4.6 Servicing the high-pressure pump

■■■■■■■■■■■■■■■■■■■■■■

60

■■■■■■■■

883 Basic IC plus

■ Ensure that no precipitates can form when changing the eluent. Salt

crystals between the piston and seal cause abrasive particles that can

find their way into the eluent. These particles lead to contaminated

valves, an increase in pressure and, in extreme cases, scratched pistons

and thus to leakages in the high-pressure pump.

Immediately successive solutions must always be miscible. If the system

must be rinsed with organic solvents, use several solvents with rising or

falling lipophilicity.

■ In order to protect the pump seals, ensure that the pump is never oper-

ated dry. Therefore ensure that the eluent supply is correctly connected

and that there is enough eluent in the eluent bottle each time before

turning on the pump.

4.6 Servicing the high-pressure pump

NOTICE

You can find a video sequence for this task in the Multimedia Guide IC

Maintenance or on the Internet at http://ic-help.metrohm.com/.

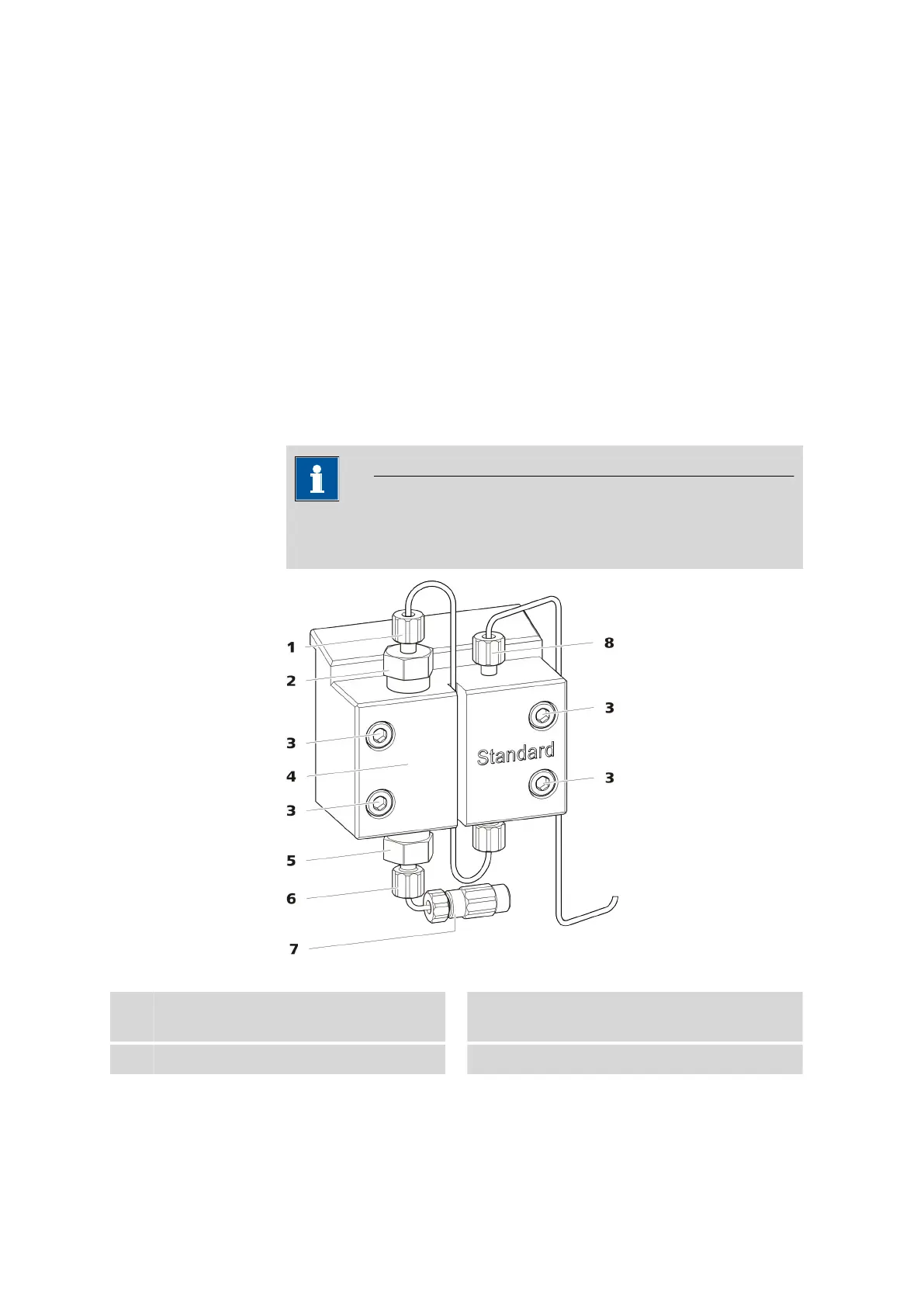

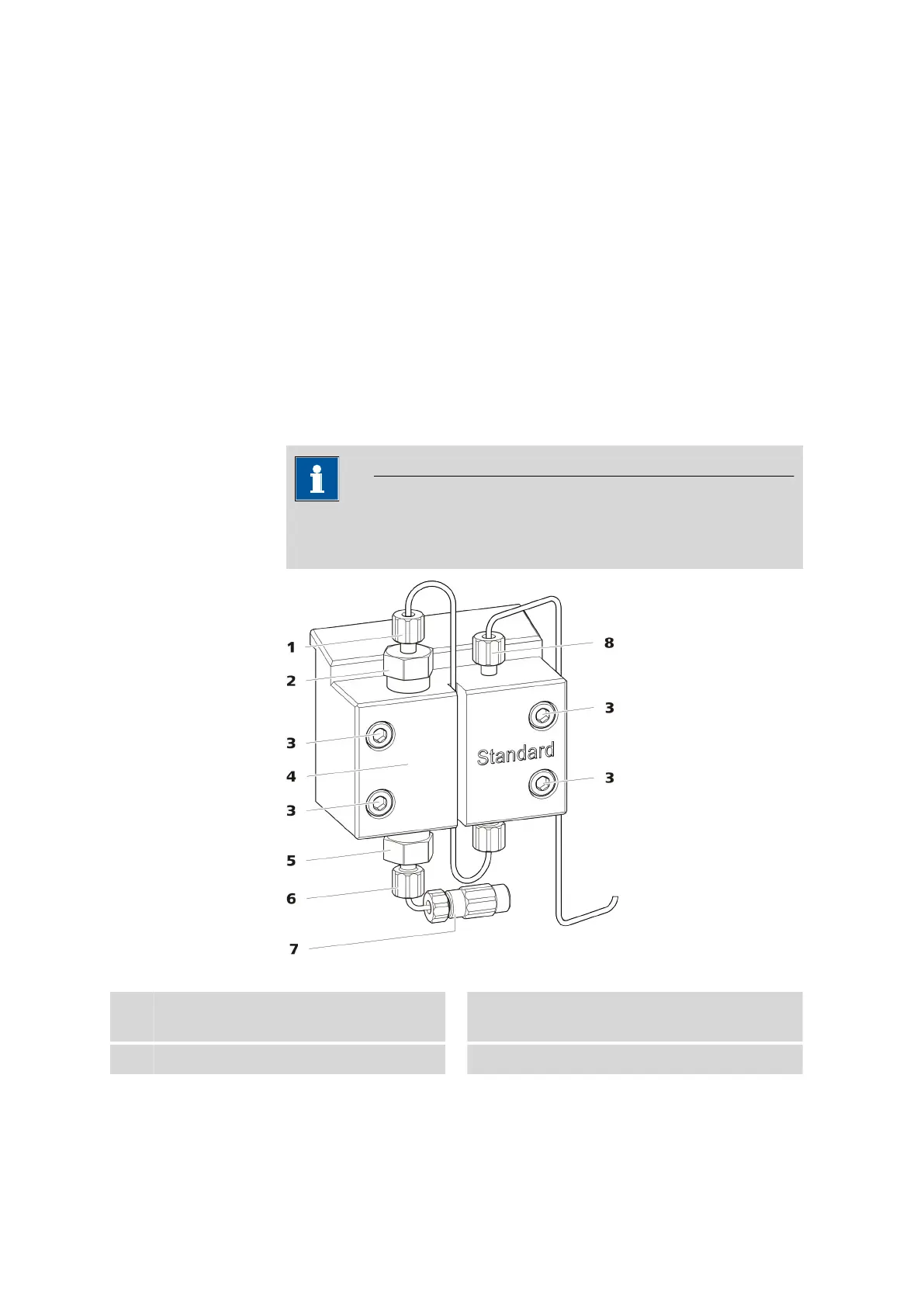

Figure 18

High-pressure pump – Parts

1

Pressure screw, short (6.2744.070)

Fastened to the outlet valve holder.

2

Outlet valve holder

3

Fastening screw

4

Pump head

Loading...

Loading...