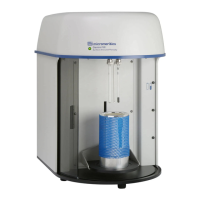

What to do if Micromeritics AccuPyc II 1340 don't turn on?

- AAngela RobertsonAug 5, 2025

If nothing happens when you turn on your Micromeritics Measuring Instruments, start by ensuring the power cord is fully inserted into both the outlet and the unit. Check if the outlet has power by plugging in another device. Wiggle the power plug to see if the display comes on, which may indicate bent prongs. A damaged power cord could also be the cause, so have an electrician inspect it. If none of these steps work, there may be a loose internal connection or a failure of the external power supply, and it is recommended to contact a Micromeritics Service Representative.