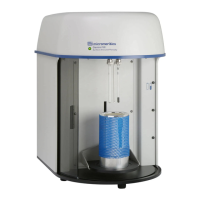

AccuPyc II 1340 Equipment Description

Aug 2013 1-5

designated purge fill pressure. The chambers are then vented to atmosphere, resulting in elimination of

water vapor or other contaminants. A cycle is used for collecting the precise, accurate data used in

report calculations.

Calibration is used to determine the size of the cell and expansion chambers within the instrument.

After calibration, the cell and expansion chamber volumes are stored automatically.

The zero function is used to calculate a new zero pressure offset. It is measured when the system is at

atmospheric pressure and thermal equilibrium and is subtracted from all subsequent pressure readings

in order to obtain a true gauge pressure.

Configurations

To ensure best fit with your sample, the AccuPyc is available in multiple configurations:

•1-cm

3

sample chamber

•10-cm

3

sample chamber

• 100-cm

3

sample chamber

• 350-cm

3

sample chamber

• 2000-cm

3

sample chamber

Best fit means your sample nearly fills the sample chamber and, therefore, optimizes the precision of

your results.

Temperature Control

A temperature-controlled unit to which an external bath is connected is available in the following

configurations:

•10-cm

3

sample chamber

• 100-cm

3

sample chamber

The temperature-controlled unit is specifically designed for temperature-sensitive materials. This unit

is ideally suited for laboratories in which ambient temperature varies during normal work hours, or in

which subambient cooling or above-ambient heating is required.

All sample chamber volumes are nominal unless otherwise specified.

Loading...

Loading...