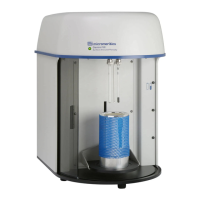

What to do if Micromeritics TriStar II 3020 Measuring Instruments sample is not within specifications?

- RRichard MooreAug 4, 2025

If your Micromeritics Measuring Instruments sample is not within specifications, there might be a leak in the manifold. You can refer to Inspecting and Changing Vacuum Pump Oil, page 9-7. Another cause could be contaminated gas. You can perform a blank analysis; if the results are good, perform a reference material analysis. You may need to replace the tank. Check for line leaks that could cause contamination and flush the lines occasionally to prevent contamination. Also, ensure the gas line is all metal, preferably the one shipped with the instrument. Avoid polymer gas lines or flexible gas lines that may be internally coated with a polymer.