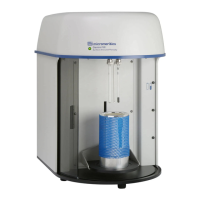

TriStar II 3020 Introduction

302-42828-01 - Dec 2012 9-1

9. TROUBLESHOOTING AND MAINTENANCE

Introduction

The analyzer has been designed to provide efficient and continuous service; however, certain mainte-

nance procedures should be followed to obtain the best results over the longest period of time. This

chapter includes maintenance and calibration procedures.

Troubleshooting

Most operational problems are caused by:

• Leaks (commonly around the sample tube O-ring at the analysis port)

• Sample weighing errors

• Use of too much analysis bath fluid in the Dewar at the start of an analysis

• Entry of incorrect system volume for analysis

• Impure gas supply

When unexpected analysis results occur, check the above first. Some common operational problems

not indicated on the screen and their respective causes and solutions are provided in the following

table:

What Happened Why What To Do

Vacuum pump is noisy. Sample tube connector is loose. Tighten fitting. Replace O-ring.

Sample tube O-ring is worn or

cracked.

Replace O-ring. Refer to

Replacing the Sample Tube O-

ring, page 9-6.

Sample tube is cracked. Replace with new sample tube.

No sample tube loaded on a

selected port.

Install plug or empty sample

tube.

Gas inlet valve open while

vacuum valve open.

With manual control enabled,

use the instrument schematic to

close gas inlet valve.

Analysis Dewar cannot be

raised (or lowered).

Elevator that moves Dewar is

stuck.

Check for possible obstruction

to elevator movement.

Analysis valves cannot be

operated.

Cable from computer to the

instrument is loose.

Make sure the cable is

connected properly

Loading...

Loading...