General

OM-244 814 Page 35

Input7 2012−05

! Turn Off welding power source, and

check voltage on input capacitors

according to Section 8-9 before

proceeding.

! Installation must meet all National and

Local Codes − have only qualified per-

sons make this installation.

! Disconnect and lockout/tagout input

power before connecting input

conductors from unit. Follow estab-

lished procedures regarding the in-

stallation and removal of lockout/

tagout devices.

! Make input power connections to the

welding power source first.

! Always connect green or

green/yellow conductor to supply

grounding terminal first, and never to

a line terminal.

. The Auto-Line circuitry in this unit

automatically links the power source to the

primary voltage being applied. Check input

voltage available at site. This unit can be

connected to any input power between 208

and 575 VAC without relinking the power

source.

See rating label on unit and check input volt-

age available at site.

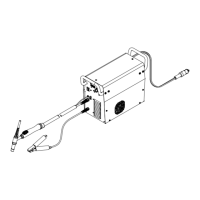

1 Input Power Conductors (Customer

Supplied Cord)

Select size and length of conductors using

Section 4-6. Conductors must comply with

national, state, and local electrical codes. If

applicable, use lugs of proper amperage

capacity and correct hole size.

Three Conductor Power Cord Preparation

2 Black And White Input Conductors

(L1 And L2)

3 Red Input Conductor

4 Insulation Sleeving

5 Green Or Green/Yellow Grounding

Conductor

6 Electrical Tape

Insulate and isolate red conductor as shown.

Welding Power Source Input Power

Connections

7 Strain Relief

Install strain relief of proper size for unit and

input conductors. Route conductors (cord)

through strain relief and tighten screws.

Connect input conductors as shown in

illustration.

8 Current Transducer

9 Welding Power Source Grounding

Terminal

10 Welding Power Source Line Terminals

Route green or green/yellow grounding

conductor through current transducer and

connect to welding power source grounding

terminal first. Then connect input conductors L1

and L2 to welding power source line terminals.

Reinstall side panel onto welding power source.

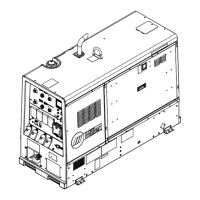

Disconnect Device Input Power

Connections

11 Disconnect Device (switch shown in

OFF position)

12 Disconnect Device (Supply) Grounding

Terminal

Connect green or green/yellow grounding

conductor (see Item 5) to disconnect device

grounding terminal first.

13 Disconnect Device Line Terminals

Connect input conductors L1 and L2 to

disconnect device line terminals.

14 Over-current Protection

Select type and size of over-current

protection using Section 4-6 (fused

disconnect switch shown).

Close and secure door on line disconnect

device. Follow established lockout/tagout

procedures to put unit in service.

8-11. Connecting 1-Phase Input Power For Axcess E 300 Only (Continued)

Notes

Work like a Pro!

Pros weld and cut

safely. Read the

safety rules at

the beginning

of this manual.

Loading...

Loading...