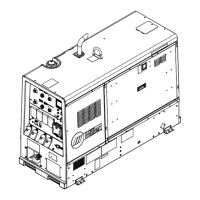

General

OM-244 814 Page 47

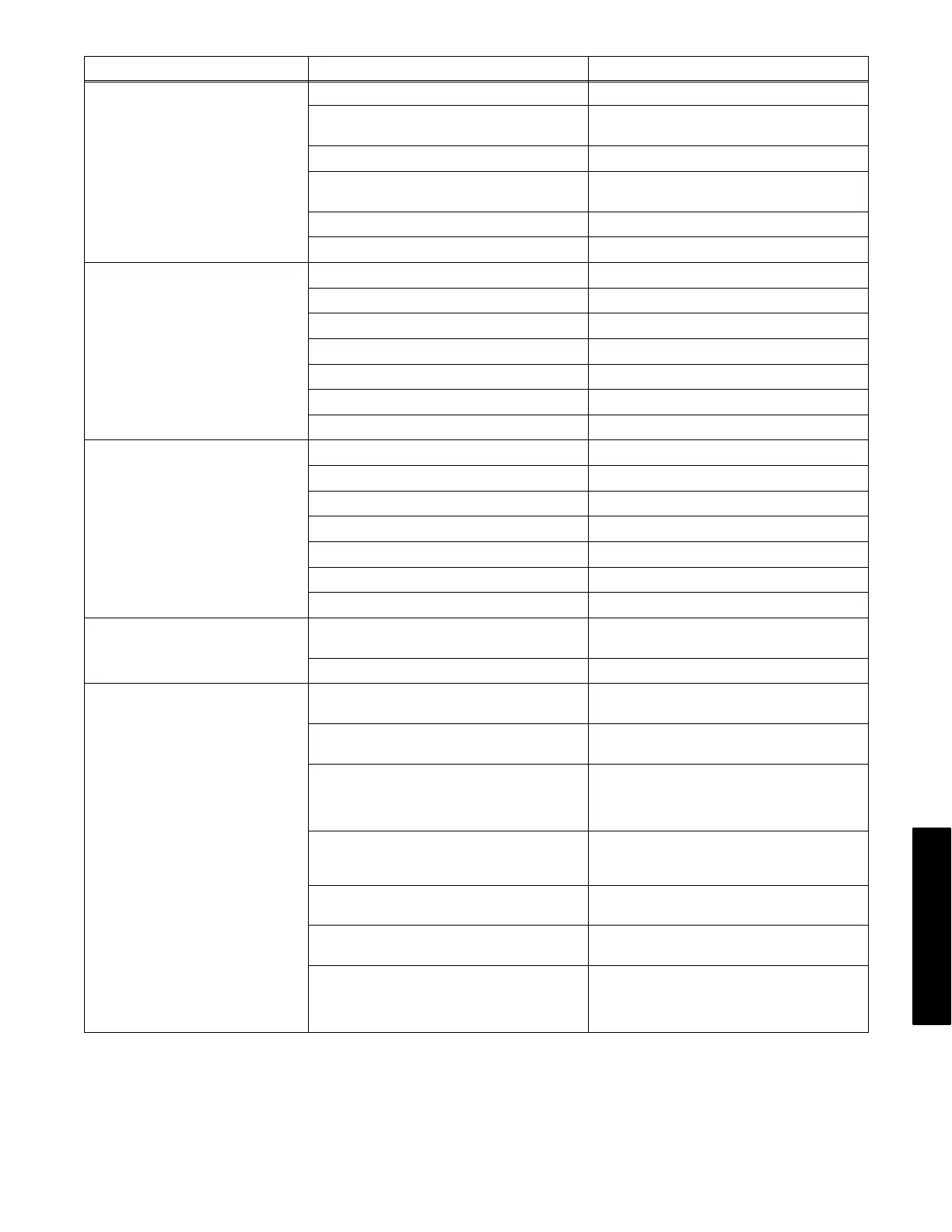

Trouble RemedyProbable Cause

Wandering, hunting or erratic arc

(Continued)

Voltage sensing leads open or shorted Repair or replace voltage sense leads

High frequency noise in the area Be sure proper grounding methods are followed

when TIG or plasma equipment is used in the area

Arc blow see Section 9-8

Drive motor tachometer or motor cable open or

shorted

Check drive motor tachometer and cables, and re-

pair or replace

Wrong size drive rolls Replace with proper size drive rolls

Too much or too little drive roll pressure Adjust drive roll pressure

Welding wire burns back to contact tip at

the start of a weld

Restriction in wire feed system Check inlet cable, gun liner and wire guides

Worn drive rolls Replace drive rolls

Wrong size drive rolls Replace with proper size drive rolls

Improper start parameters Adjust start parameters

Worn contact tip Replace contact tip

Wrong size or type of contact tip Replace with proper size and type contact tip

Not enough cast in welding wire Add a wire straightener to put cast in wire

Welding wire burns back to contact tip

during welding

Restriction in wire feed system Check inlet cable, gun liner and wire guides

Worn drive rolls Replace drive rolls

Wrong size drive rolls Replace with proper size drive rolls

Too much or too little drive roll pressure Adjust drive roll pressure

Worn contact tip Replace contact tip

Wrong size or type of contact tip Replace with proper size and type contact tip

Not enough cast in welding wire Add a wire straightener to put cast in wire

Welding wire burns back to contact tip at

the end of a weld

Welding power source output not shutting off Make sure all switches are in correct position, re-

pair power source if necessary

Burnback setting too high or too long Adjust burnback setting or turn off completely

Shutdown at arc initiation using power

source and feeder or interface

No voltage feedback signal Broken or disconnected voltage feedback lead, no

open circuit voltage, check power source

No current feedback signal Poor parameters, open in weld circuit, faulty hall

device, check power source

No tachometer sensing No wire speed command from robot, material

jammed in drive gears, faulty tachometer in drive

motor, wire feed drive circuit board, or motor cable,

check wire feed system

Poor parameters preventing arc stability Check for proper pulse program, material, welding

wire, shielding gas, voltage setting, and wire speed

setting

Arc start error Check contact tip, wire feed system and weld cir-

cuit

No start signal from robot Check robot setup and interconnect cable connec-

tion between robot controller and interface

No wire feed with wire feed motor running Wire stuck in contact tip, worn or wrong size drive

rolls, improper drive roll pressure setting, or wire

not unspooling or restriction in drum adapter, check

wire feed system

Loading...

Loading...