OM-244 814 Page 48

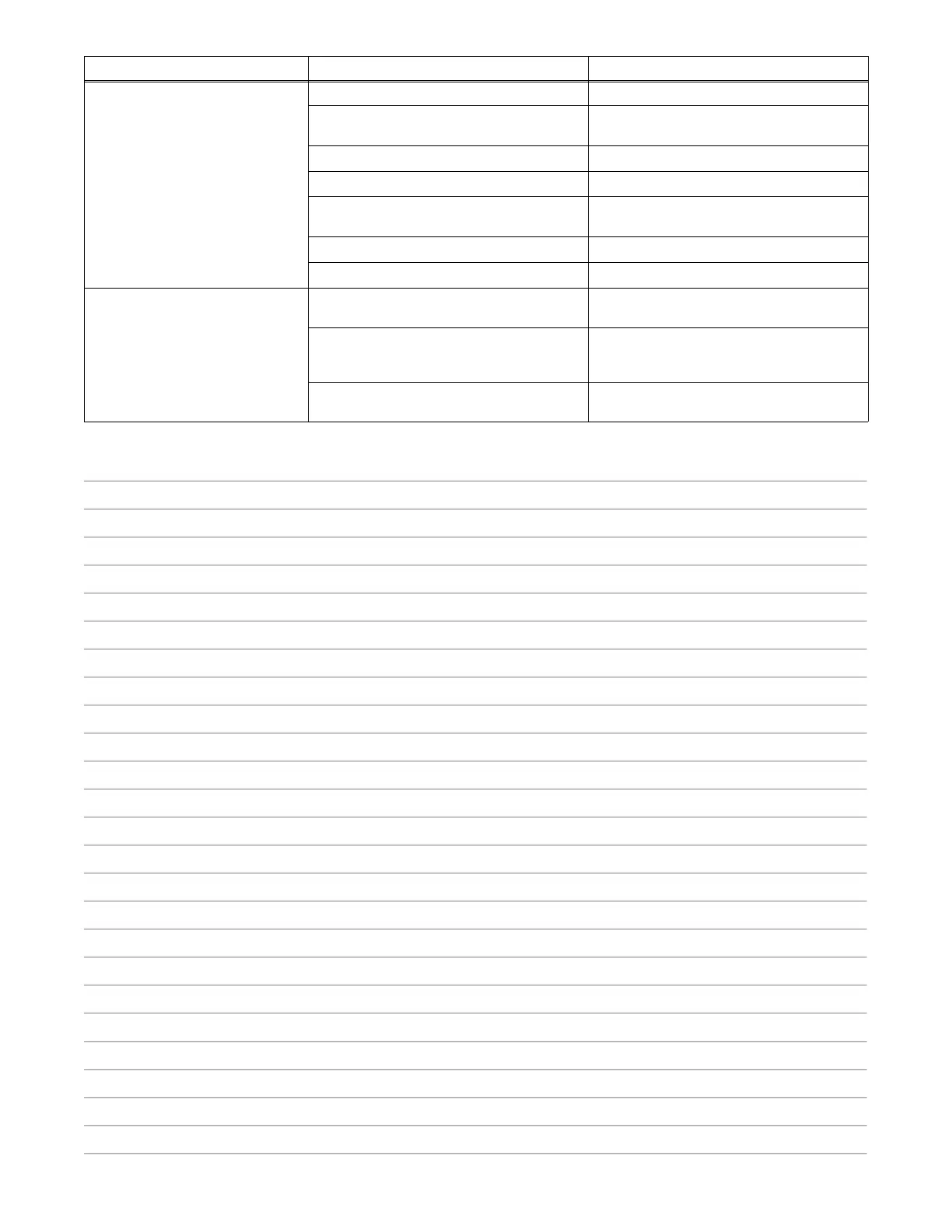

Trouble RemedyProbable Cause

Shutdown at arc initiation using robot

controller

No arc detected Check for arc detect signal coming from interface

Robot times out before arc detected Add more time for robot arc detect input, verify weld

parameters, and check weld circuit

Robot command scaling not set properly Set proper robot command scaling

Time between welds too short Adjust welding cycle time

Welding sequence problems Power source should energize and welding wire

should start feeding at the same time

No wire feed speed command Set wire feed speed

No voltage command Set voltage

Shutdown at arc initiation due to weld cir-

cuit condition

Poor part fit up at weld joint, wire not making contact

with workpiece

Check part consistency for fitup and/or position gun

so wire always contacts part

Poor connection in weld circuit Check welding gun, torch, contact tip adapter, con-

tact tip, weld cable connections and any rotary or

brush type connection

Improper gas flow causing start and timeout issues Check for correct shielding gas and flow adjust-

ment

Notes

Loading...

Loading...