OM-281426 Page 38

F

Complete Parts List is available at www.MillerWelds.com

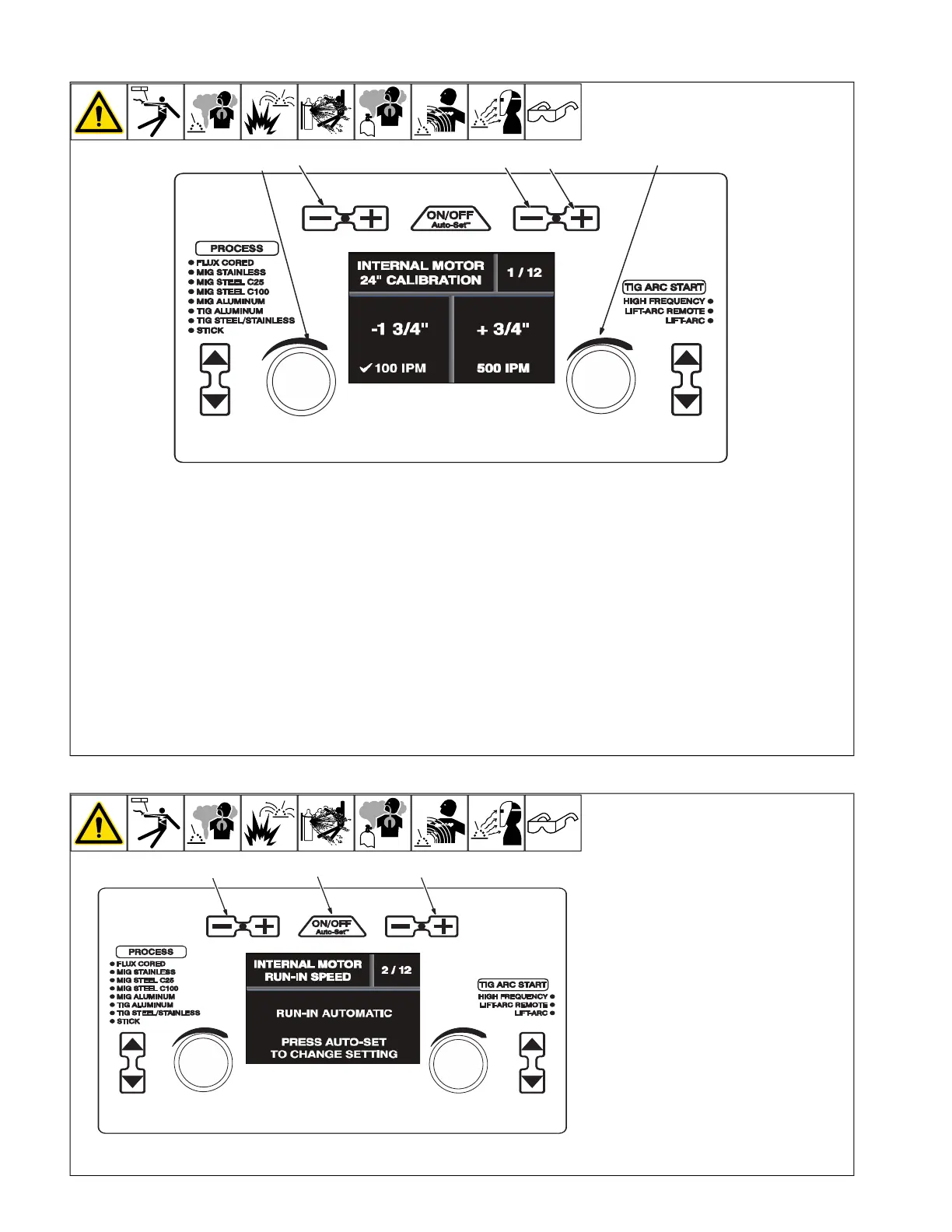

6-9. Internal Motor 24 Inch Calibration (Menu 1 Of 12)

A complete Parts List is available at www.MillerWelds.com

OM-281426 Page 27

3-9. Internal Motor 24 Inch Calibration (Menu 1 Of 12)

Ref. 281252A

1

3

2

4

5

3-10. Internal Motor Run-In Speed (Menu 2 Of 12)

Ref. 281252A

1

2

3

F

The unit’s internal drive motor is cali-

brated at the factory. No calibration is

needed unless drive motor or control

board is changed.

1 Wire/Rod/Tungsten Minus (-) Button

2 Material Thickness Plus (+) Button

3 Material Thickness Minus (-) Button

4 Left Adjustment Knob

5 Right Adjustment Knob

Cut wire flush at nozzle.

Follow instructions in Section 6-8 to enter

the setup menu.

To perform a motor calibration 24 in. run-out

test at 100 ipm, turn left Adjustment knob,

and verify that a check mark appears next to

100 ipm.

Be sure wire is cut flush at nozzle, then trig-

ger the MIG gun. Motor will feed approxi-

mately 24 in. of wire through gun.

Cut wire flush at nozzle and measure run-

out. If length of run-out is not 24 in., turn left

Adjustment knob to increase/decrease

length of run-out.

To perform a motor calibration 24 in. run-out

test at 500 ipm, turn right Adjustment knob,

and verify that a check mark appears next to

500 ipm.

Be sure wire is cut flush at nozzle, then trig-

ger the MIG gun. Motor will feed approxi-

mately 24 in. of wire through gun.

Cut wire flush at nozzle and measure run-

out. If length of run-out is not 24 in., turn

right Adjustment knob to increase/decrease

length of run-out.

To exit menu, simultaneously press and re-

lease the Wire/Rod/Tungsten Minus (-) but-

ton and Material Thickness Plus (+) button,

or turn unit off and on.

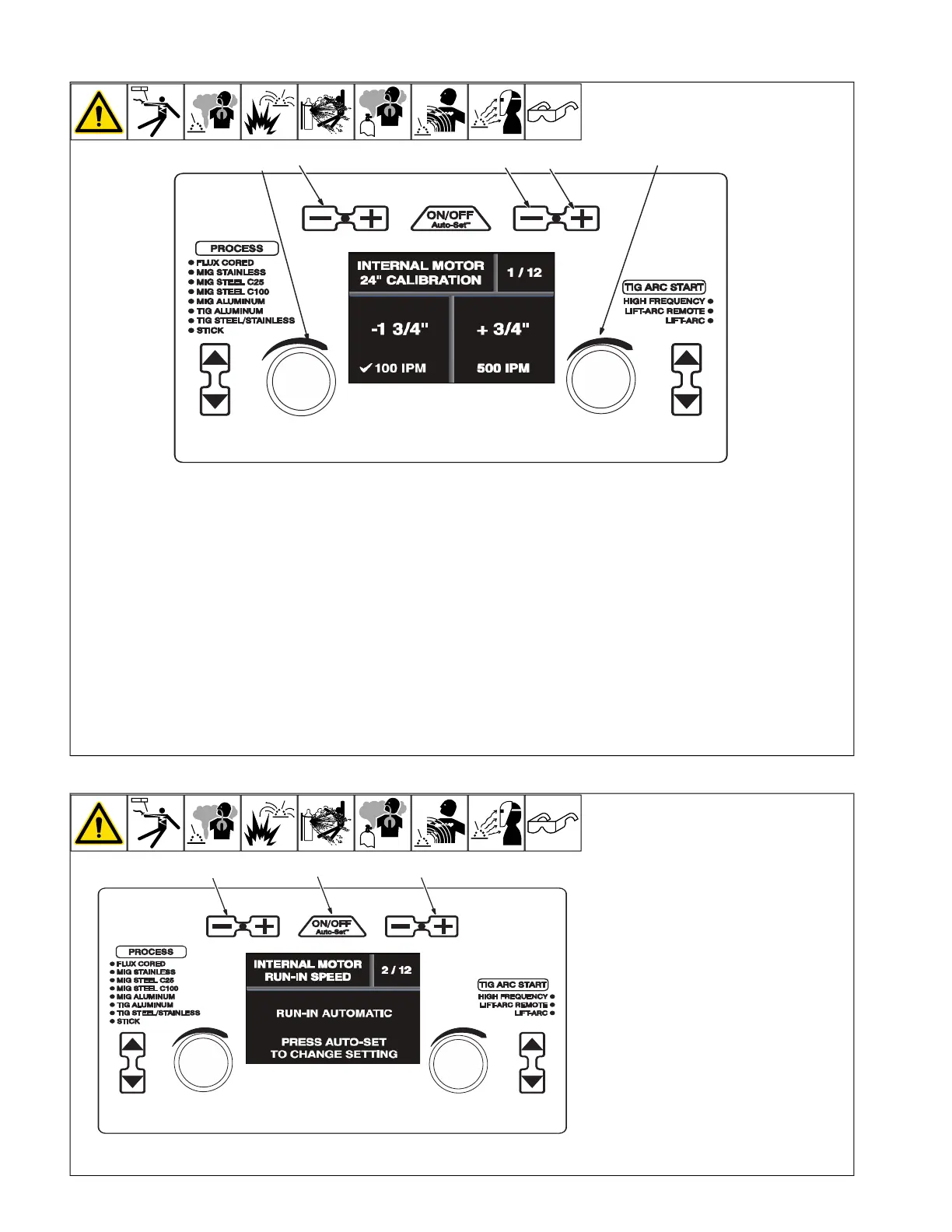

6-10. Internal Motor Run-In Speed (Menu 2 Of 12)

A complete Parts List is available at www.MillerWelds.com

OM-281426 Page 27

3-9. Internal Motor 24 Inch Calibration (Menu 1 Of 12)

Ref. 281252A

1

3

2

4

5

3-10. Internal Motor Run-In Speed (Menu 2 Of 12)

Ref. 281252A

1

2

3

1 Wire/Rod/Tungsten Minus (-) Button

2 Auto-Set Button

3 Material Thickness Plus (+) Button

Follow instructions in Section 6-8 to enter

the setup menu.

To change the run-in setting, press the Auto-

Set button.

Run-in is the wire speed prior to the welding

arc being struck. When set to Automatic, the

welder determines the optimal run-in speed

for each start. When set to disabled, the run-

in speed is the same as the weld wire speed.

To exit the menu, simultaneously press and

release the Wire/Rod/Tungsten Minus(-) but-

ton and Material Thickness Plus (+) button,

or turn unit off and on.

Loading...

Loading...