OM-281426 Page 57

Wire Size Amperage Range Recommended Wire Feed Speed Wire Feed Speed *

0.023 in. (0.58 mm) 30-90 A 3.5 in. (89 mm) per amp 3.5 x 62.5 A = 219 ipm (5.56 mpm)

0.030 in. (0.76 mm) 40-145 A 2 in. (51 mm) per amp 2 x 62.5 A = 125 ipm (3.19 mpm)

0.035 in. (0.89 mm) 50-180 A 1.6 in. (41 mm) per amp 1.6 x 62.5 A = 100 ipm (2.56 mpm)

*62.5 A based on 1/16 in. (1.6 mm) material thickness. ipm = inches per minute; mpm = meters per minute

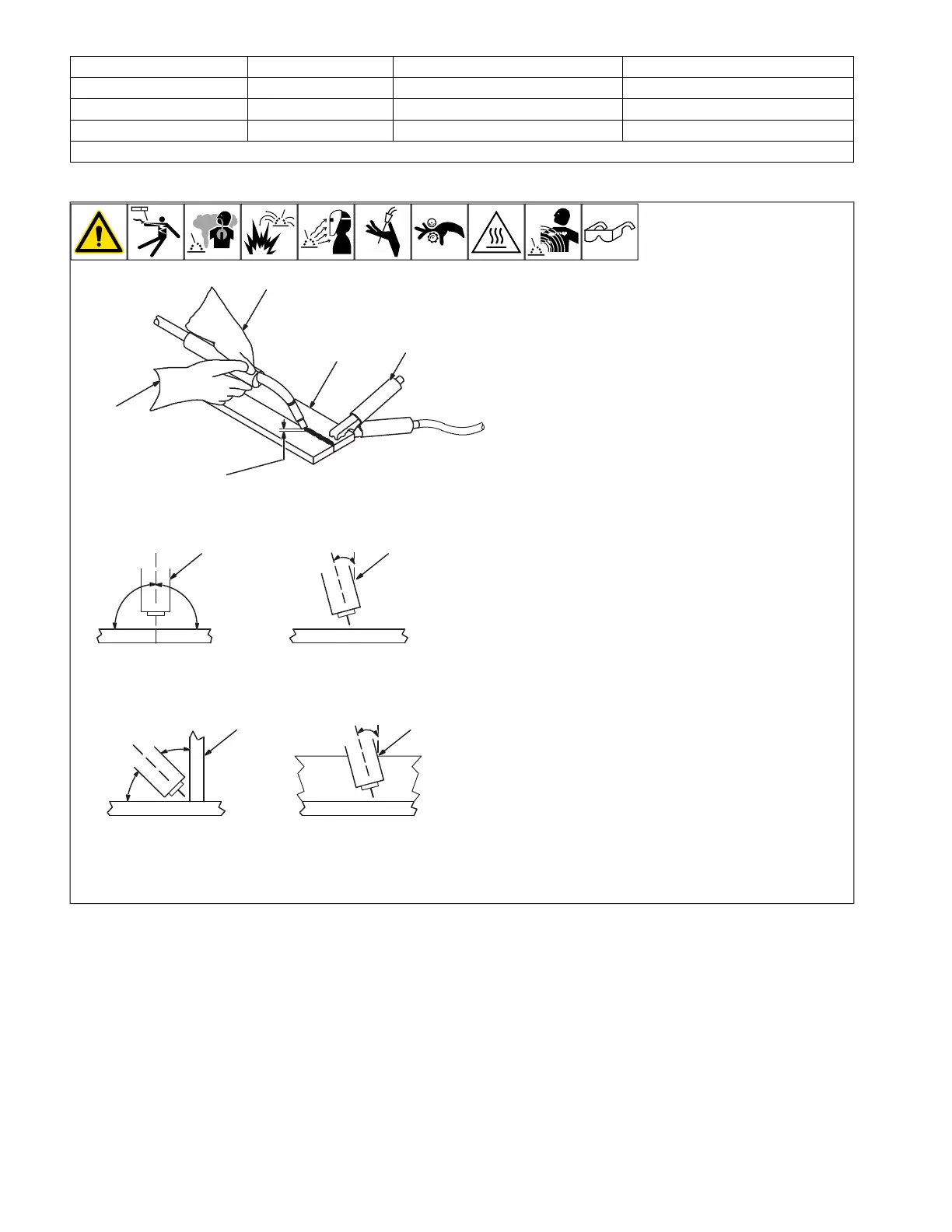

12-3. Holding And Positioning Welding Gun

OM-4419 Page 1

SECTION 1 GMAW WELDING (MIG) GUIDELINES WHEN

USING A VOLTAGE-SENSING FEEDER

1

2

3

4

5

6

7

8

2

3

5

4

90° 90°

0°-15°

45°

45°

1

0°-15°

1-1. Holding And Positioning Welding Gun

6 7 6 7

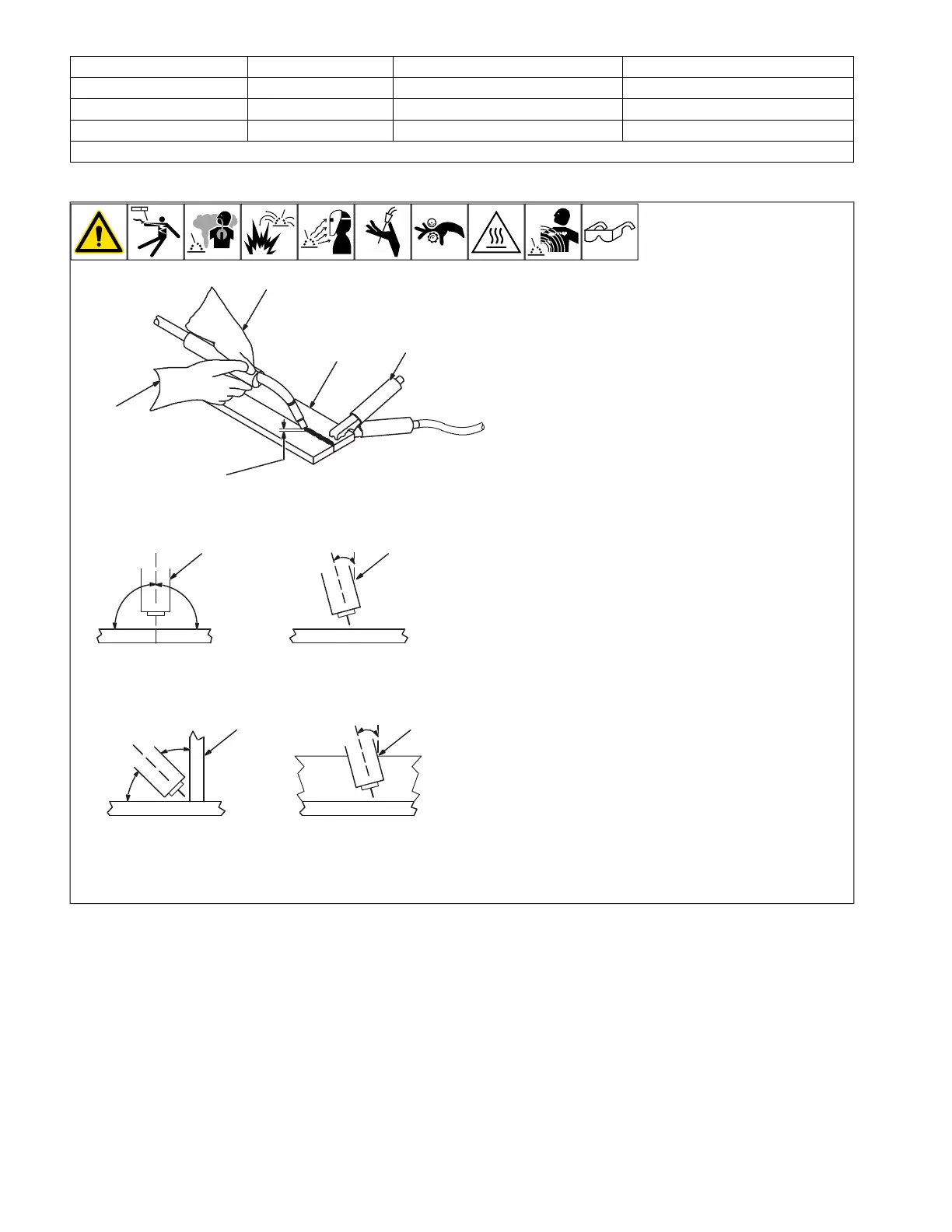

Groove Welds

90

°

90

°

0

°

-15

°

45

°

45

°

0

°

-15

°

6 7 6 7

Fillet Welds

90

°

90

°

0

°

-15

°

45

°

45

°

0

°

-15

°

6 7 6 7

F

Welding wire is energized when gun

trigger is pressed. Before lowering hel-

met and pressing trigger, be sure wire

is no more than 1/2 in. (13 mm) past

end of nozzle, and tip of wire is posi-

tioned correctly on seam.

1 Hold Gun and Control Gun Trigger

2 Workpiece

3 Work Clamp

4 Electrode Extension (Stickout)

Solid Wire – 3/8 to 1/2 in. (9 to 13 mm)

5 Cradle Gun and Rest Hand on

Workpiece

6 End View Of Work Angle

7 Side View Of Gun Angle

Loading...

Loading...