The HYDRO+ monitors levels 0.3 to 15 m (1 to 50 ft) from the transducer face, with

outstanding accuracy, usually within 0.25% of range. (Ensure the transducer selected

suits the material and measurement range monitored).

This versatility is accomplished by Milltronics patented Sonic Intelligence

TM

, providing

high measurement reliability, regardless of operating conditions.

The HYDRO+ provides the following

LCD

(Liquid Crystal Display) Readings:

» Level, space, distance, volume, or remaining capacity in open or closed vessels.

» Differential level across a channel filter or screen (2 transducers required).

» Average level in a large vessel with an uneven material surface (2 transducers).

» Head, flow, or totalized flow in free flowing open channels.

» Pumped volume from wet wells or into reservoirs.

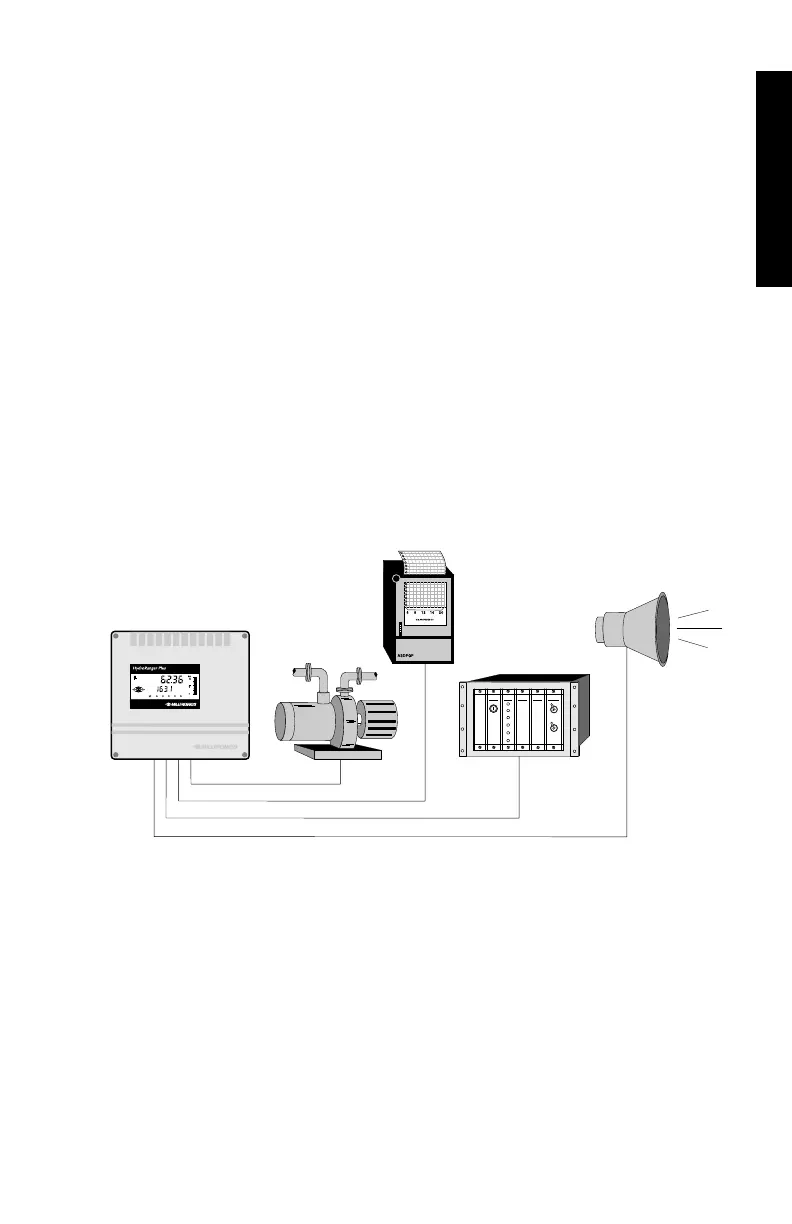

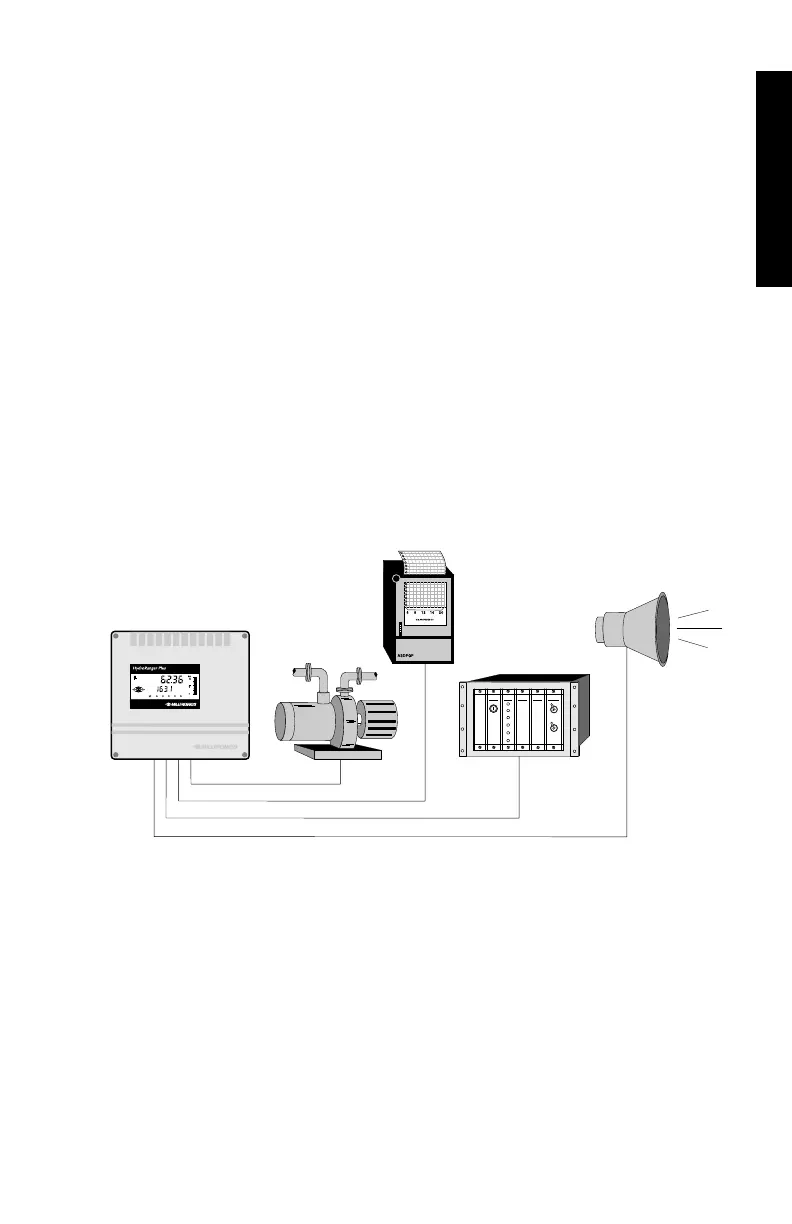

The HYDRO+ relays and/or mA output may be used as preset (or programmed as

desired) to activate alarms, pump controls, chart recorders, or virtually any process

control equipment.

The HYDRO+ infrared interface permits one programmer to be used for any number

of HYDRO+ level monitors. Upon programming completion, the programmer may be

locked away for programming security. All Operator programming is stored in

non-volatile memory, unaffected by power interruption.

While the HYDRO+ is typically used to monitor liquid level, any process which

requires a distance measurement or object presence/lack of presence (within the

system maximum measurement range) is a candidate for HYDRO+ application.

Refer to APPLICATIONS for detailed descriptions of a small sample of process

measurement requirements to which the HYDRO+ may be applied.

3

2

1

4

5

%

PLC

Chart

Recorder

Pump

HYDRO +

INTRODUCTION

PL-507 7

Loading...

Loading...