Chapter 9

196

Logic programming – Function blocks

Function test

In some applications, safeguarding devices require cyclic physical testing in order to

verify that the device continues to operate properly.

If the Safety gate monitoring function block is configured with the Function test

required parameter, the input signal(s) must change once per machine cycle in a way

that no enable condition exists anymore and back (e.g. as a result of opening and

closing of a safety gate).

Typically the Function test request input is connected to the machine cycle contact.

If according to the configuration a function test is required, this has to be performed

under the following conditions:

after the MELSEC-WS safety controller has changed from the Stop state to the Run

state, and

after each rising edge (Low to High) at the Function test request input.

This is indicated by a High signal at the Function test required output. The Function

test required output changes back to Low, if a signal sequence occurs at the inputs

that causes the Enable output to change from Low to High, before the next rising

edge at the Function test request input occurs.

The Function test error output becomes High and the Enable output becomes Low,

if the next machine cycle starts before a function test has been performed, i.e. if the

Function test required output is still High and another rising edge (Low to High) at

the Function test request input occurs.

The Function test error output changes back to Low, if a signal sequence occurs at

the inputs that causes the Enable output to change from Low to High.

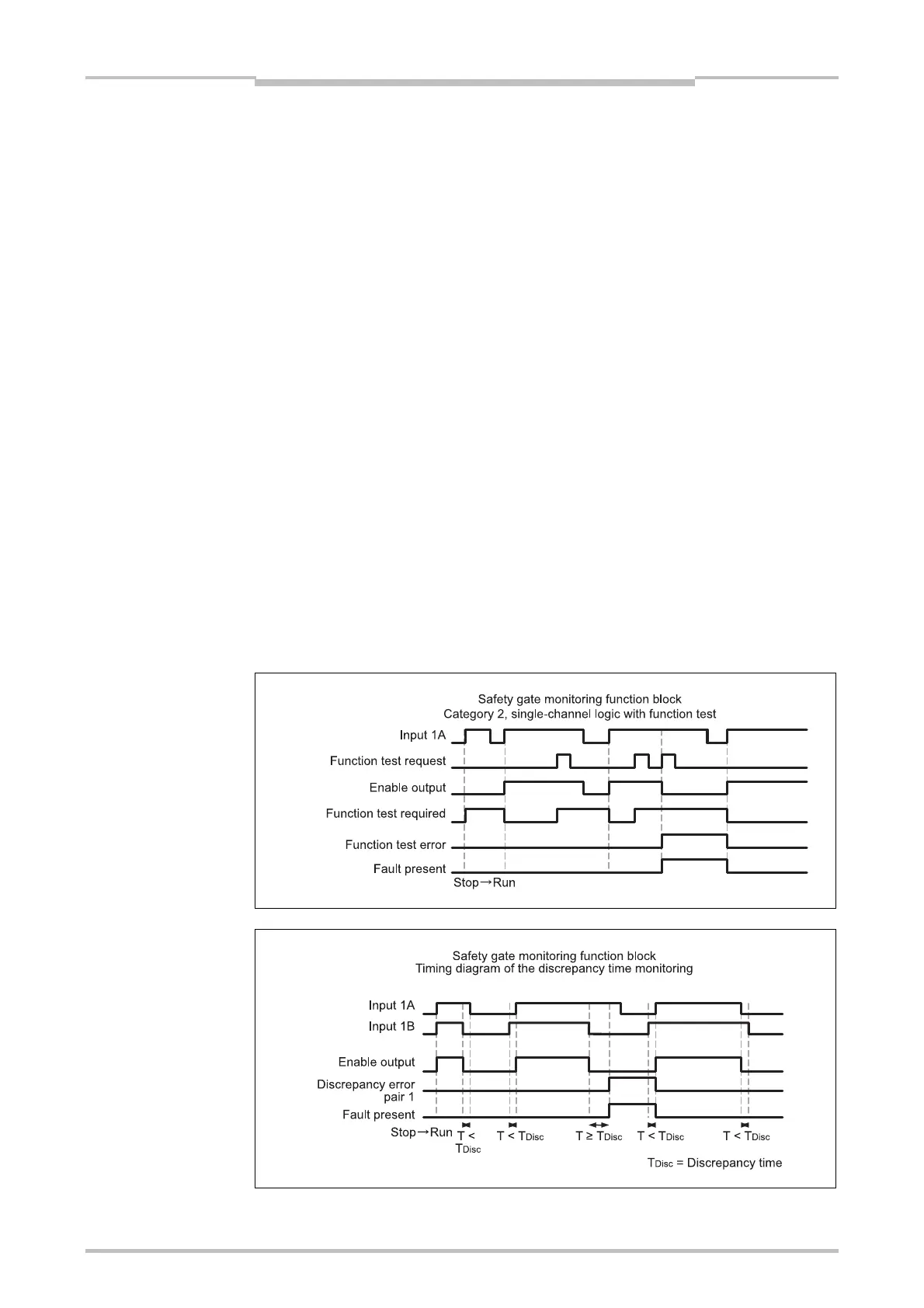

Sequence/timing diagrams

Figure 183:

Sequence/timing diagram

for the Safety gate

monitoring function block,

Category 2, single-channel

with function test

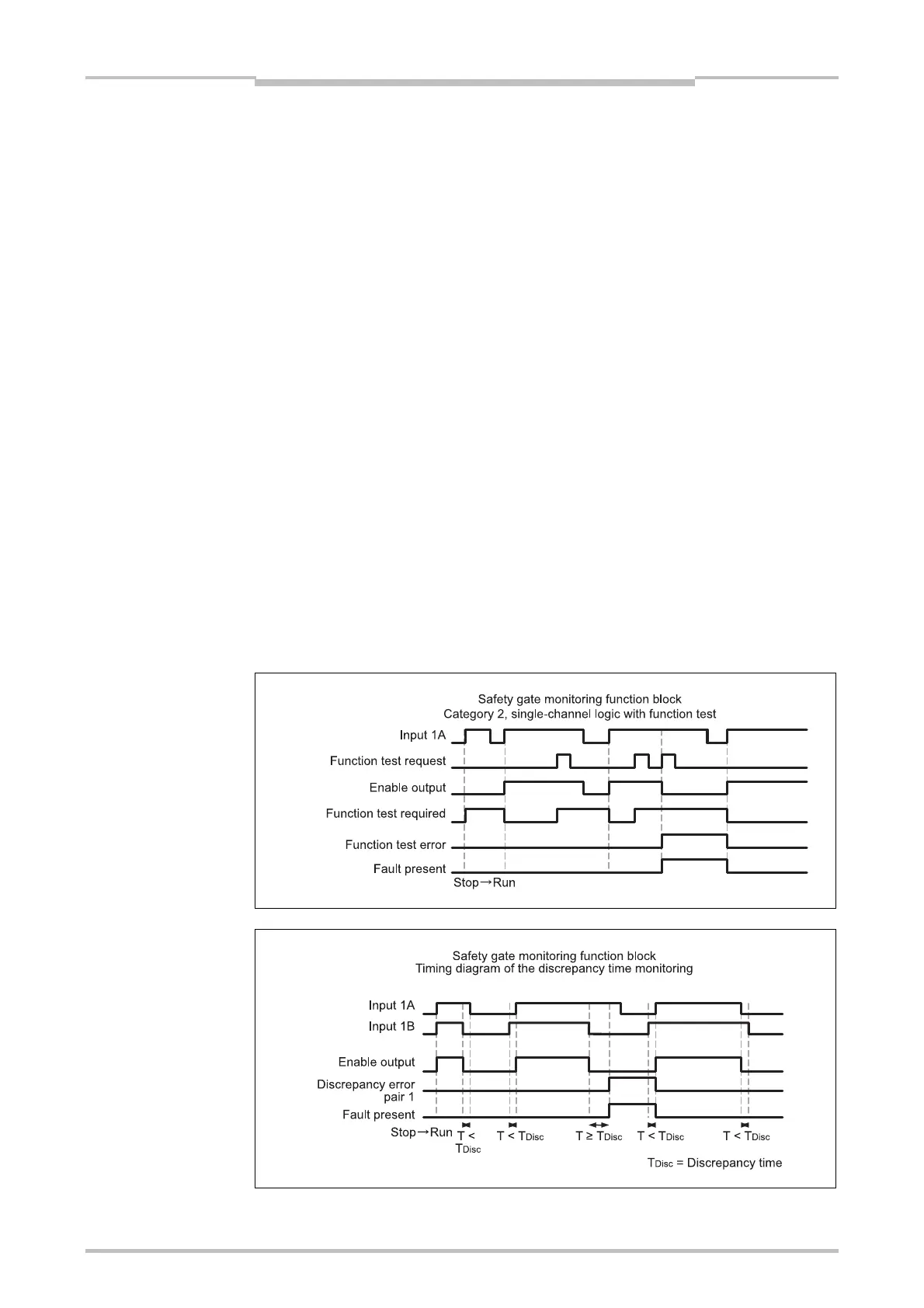

Figure 184:

Sequence/timing diagram

for the Safety gate

monitoring function block,

Category 4, dual-channel

equivalent (1 pair) without

function test

Loading...

Loading...