Chapter 9

226

Logic programming – Function blocks

9.11 Function blocks for press contact monitoring

9.11.1 Overview and general description

For press applications there are two complementary types of function blocks offered.

This section describes the contact monitoring function blocks, which provide signals

for the press cycle control function blocks.

There are two different function blocks for press contact monitoring which can be used

to monitor the correct cam signal sequence and the correct stopping (overrun) of the

press. The outputs of these function blocks indicate the current press cycle phase in

which the press is operating (e.g. upstroke or top). Typically the Enable output, Top

output and Upstroke output of a contact monitoring function block are connected to

the corresponding inputs of one or more press cycle control function blocks.

Eccentric press Universal press

Typical press types

Eccentric press Eccentric press

Hydraulic press

Press travelling

directions

Forward Forward and backward

Cams

Overrun cam

Upstroke cam

Dynamic cam

Top dead center (TDC)

Bottom dead center (BDC)

Overrun cam

Top position

condition

When Overrun cam = High When TDC = Low

Upstroke condition

When Upstroke cam = High When BDC = High

Overrun monitoring

Optional Optional

Disable monitoring

Optional Optional

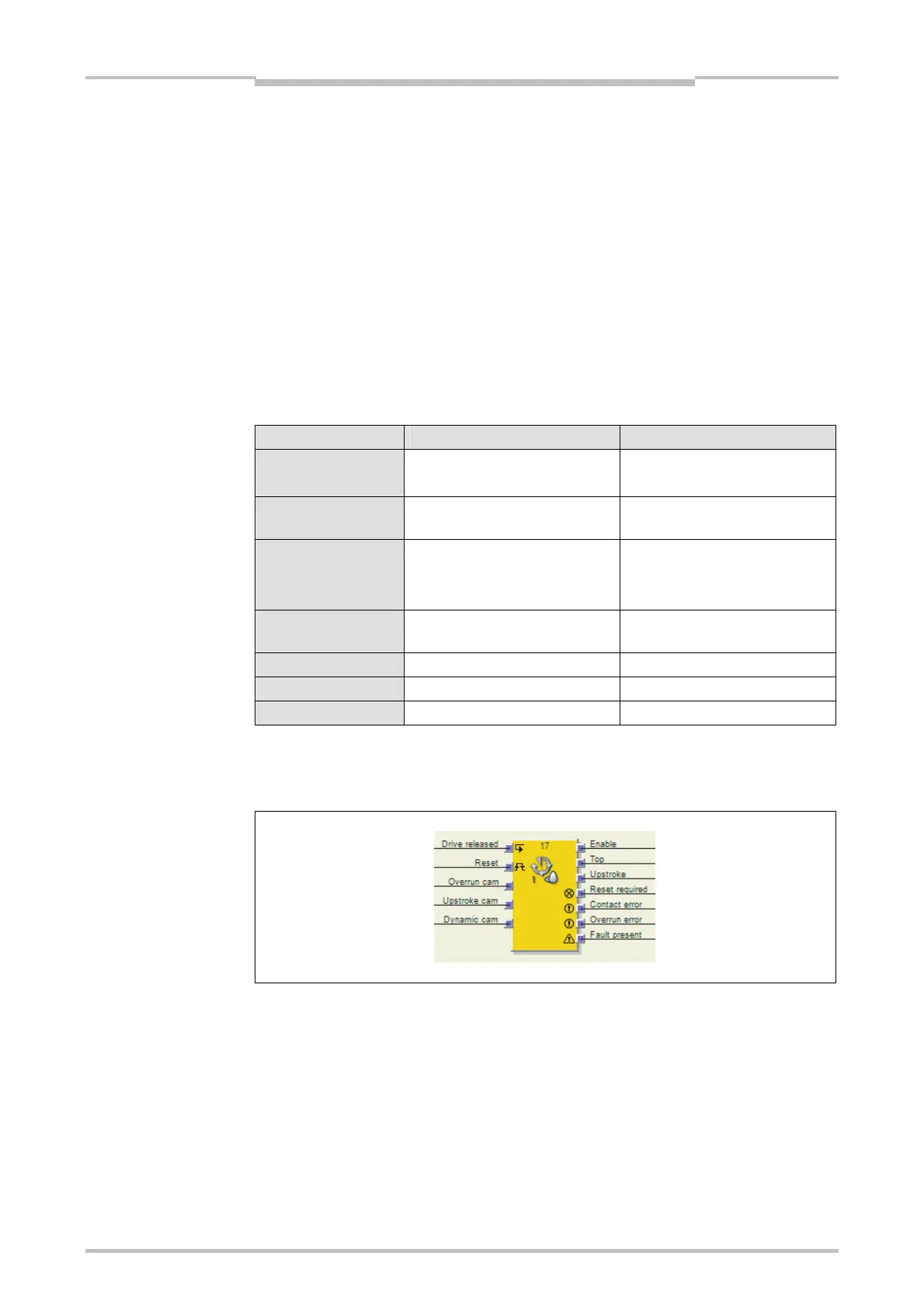

9.11.2 Eccentric press contact

Function block diagram

General description

The Eccentric press contact function block can be used for specific types of eccentric

presses (i.e. mechanical presses). The minimum configuration requires an Overrun

cam and the Upstroke cam. Optionally a Dynamic cam can also be connected.

Table 106:

Overview of the press

contact monitoring function

blocks

Figure 211:

Function block diagram for

the Eccentric press contact

function block

Loading...

Loading...