Chapter 9

212

Logic programming – Function blocks

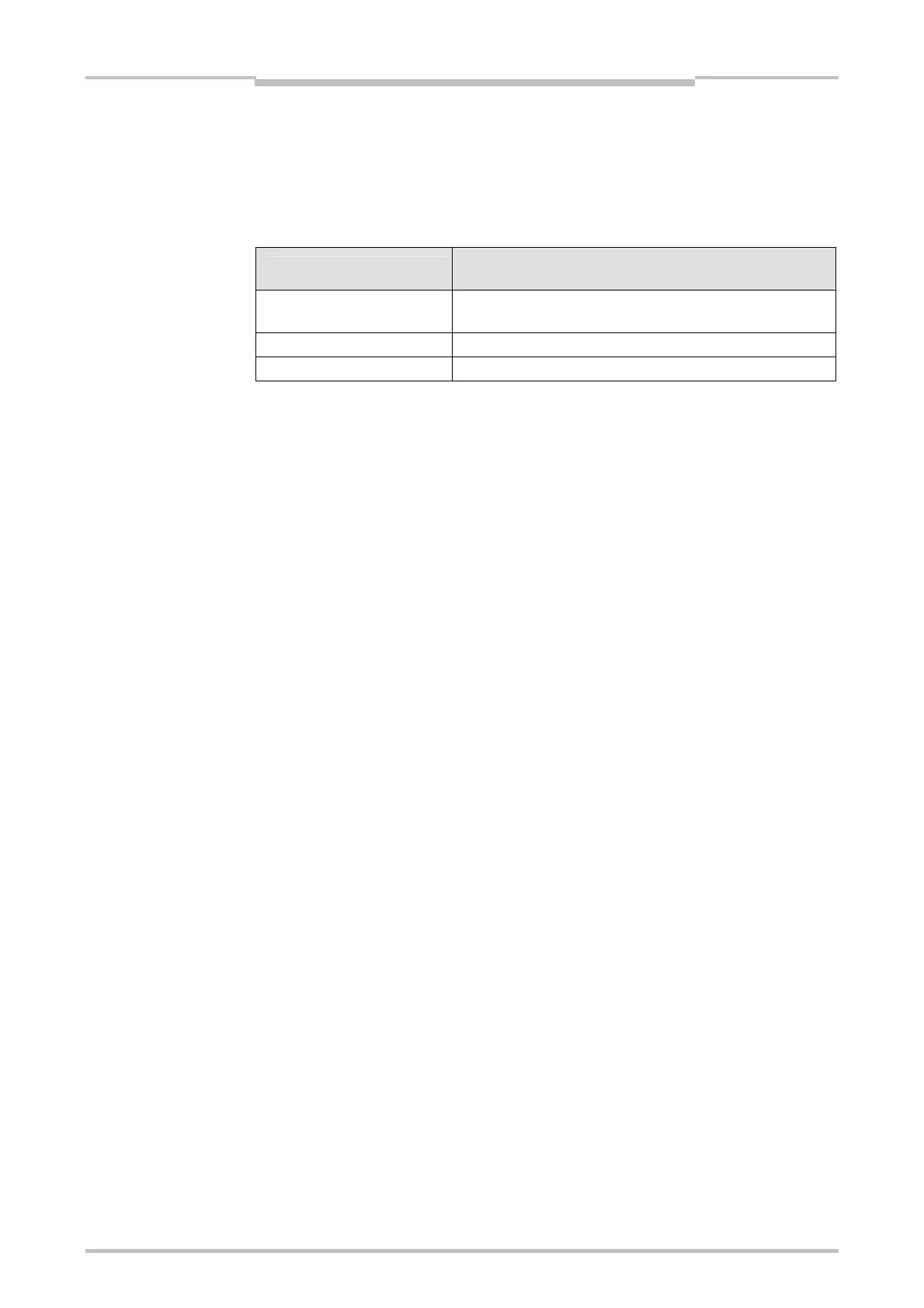

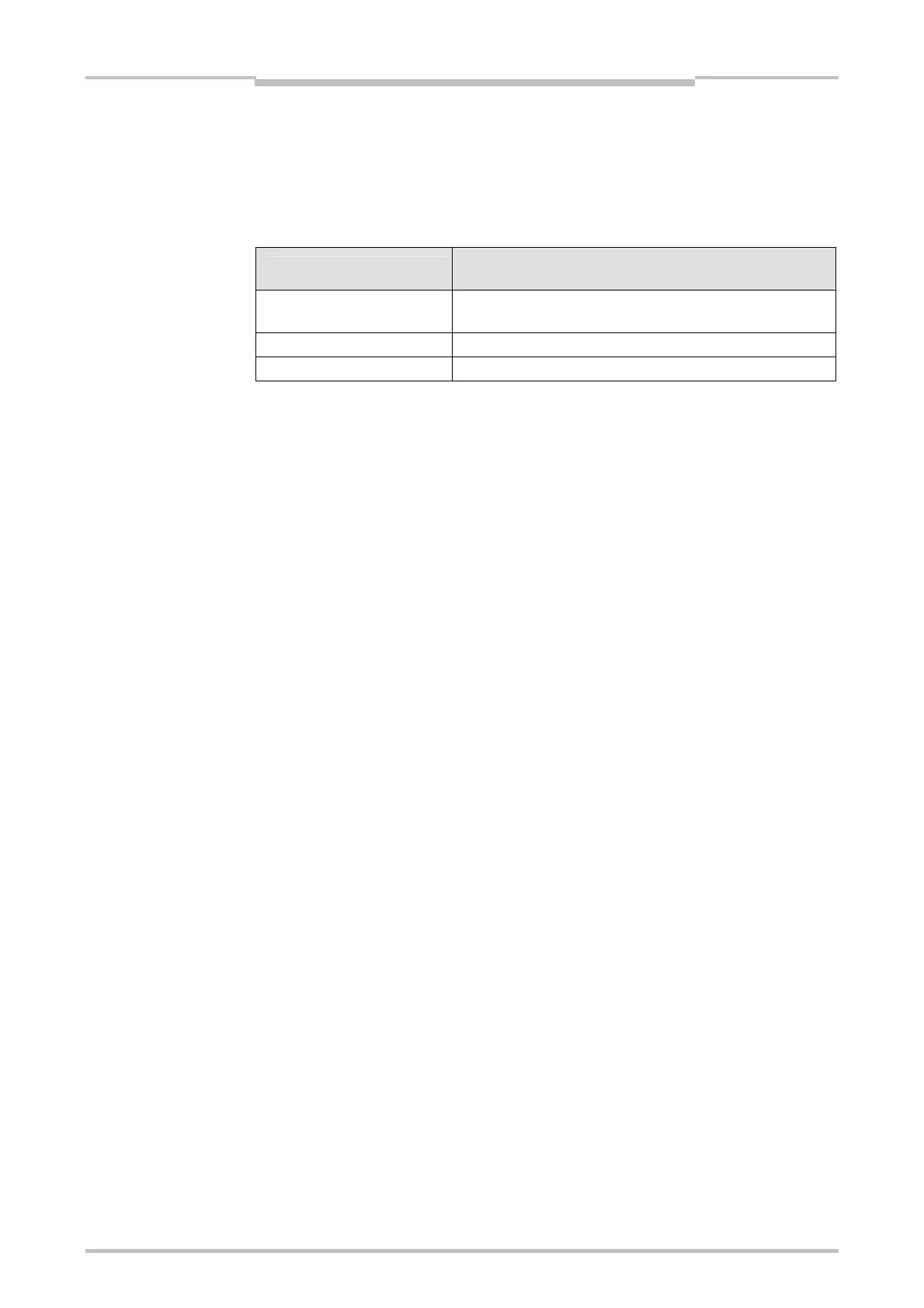

Sequence monitoring

Sequence monitoring is used to define a special mandatory sequence in which the

muting sensors have to be High. Table 93 shows the valid sequence for muting

sensor input signals. This parameter is only available for configurations with four

muting sensors, for example for parallel muting or sequential muting.

Direction detection

Requirement for the muting sensor signal inputs for

sequence monitoring:

Disabled A1 before A2 before B1 before B2 or

B2 before B1 before A2 before A1

Forward A1 before A2 before B1 before B2

Backward B2 before B1 before A2 before A1

This parameter depends on the function block. Deviations from the sequence shown

above result in a muting error, indicated by the Muting error output. In order to avoid

machine downtime the configured time for the Sensor signal gap monitoring should

furthermore be shorter than the time span that the transported object requires to pass

a muting sensor pair (e.g. A1/A2 or B1/B2).

C1 input

The C1 input is used as an additional measure to avoid manipulations. If C1 is used, a

transition from Low to High has to take place before the first muting sensor pair

becomes High. Input C1 must then remain High until both sensors of the muting

sensor pair are High so that a valid muting condition can arise. If this condition is not

fulfilled, this results in a muting error, indicated by the Muting error output. The C1

input subsequently has to return to Low again before the next muting cycle is

permitted.

Override input

An Override input signal is used to remove transported objects that have remained in

the protective field of the protective device (e.g. safety light curtain) after power

failures, triggering of an emergency stop, muting errors or similar circumstances.

The Override status output (available from firmware V3.02) changes to high and the

Override required output pulses at 2 Hz, if the following conditions are met:

Muting is currently inactive (i.e. Muting status is Low).

At least one muting sensor is High.

The OSSDs of the ESPE are Low (e.g. safety light curtain is interrupted).

The Enable output is Low.

If the conditions for the Override required output are fulfilled and a valid override

pulse sequence with a Low-High-Low transition (minimum 100 ms or 350 ms and

maximum 3 s; longer or shorter pulses are ignored) has occurred at the Override

input, the Enable output becomes High, as if the muting conditions were fulfilled.

When all muting sensors have returned to Low and the OSSD input of the ESPE is

High (e.g. indicating that the protective field of a safety light curtain is now clear), the

next valid muting cycle is expected. If the next object does not fulfill the conditions for

a muting cycle, but the conditions for the Override required output, a further override

cycle can be used in order to remove the transported material. The number of override

cycles is limited (see Table 95).

Table 93:

Requirements for sequence

monitoring

Loading...

Loading...