<HMS140V>

Emptying the vessel

The vessel in indoor unit is emptied by opening the valve

(QM1) and safety valve (FL2).

NOTE

When the vessel in indoor unit is emptied via the valve

(QM1), some water will remain in the coil and in the

heat exchanger.

This means that there is a risk of the heat exchanger,

pipes and valves f reezing at low temperatures as well

as a hygienic risk f or the coil in the hot water section.

Safety relief

valve position

5 m higher 0 m 5 m lower

system water

volume (

ℓ

)

540 470 360

Safety relief

valve position

5 m higher than

expansion vessel

0 m

5 m lower than

expansion vessel

system water

volume (

ℓ

)

390 330 240

Dimensioning expansion vessel

Internal volume in HMA100V and HMA100VM for calculating

expansion vessel is 280

ℓ

. The expansion vessel’s volume must

be at least 5 % of the total volume.

HMS140V has 18

ℓ

of expansion vessel. which can cover the

total system water volume mentioned in the below table.

Ifthesystemvolumeexceedsthelimit,extraexpansionvessel

is necessary. Install it in the same level and same pre-pressure

as the original one.

Alternatively,byreducingthewaterreserve*to1ltr,itispossible

to increase the system volume.

*waterreserve:initialwatervolumeintheexpansionvessel

when the system is f illed with water

Initial pressure and max height difference

The initial pressure of the pressure expansion vessel must be

dimensioned according to the maximum height (H) between

thevesselandthehighestpositioned radiator,seefigure.An

initial pressure of 0.5 bar (5 mvp) means a maximum permitted

height difference of 5 m.

If the standard initial pressure in the pressure vessel is not high

enough it can be increased by filling via the valve in the

expansion vessel. The expansion vessel’s standard initial

pressure must be entered in the check list on User’s manual.

Any change in the initial pressure affects the ability of the

expansion vessel to handle the expansion of the water.

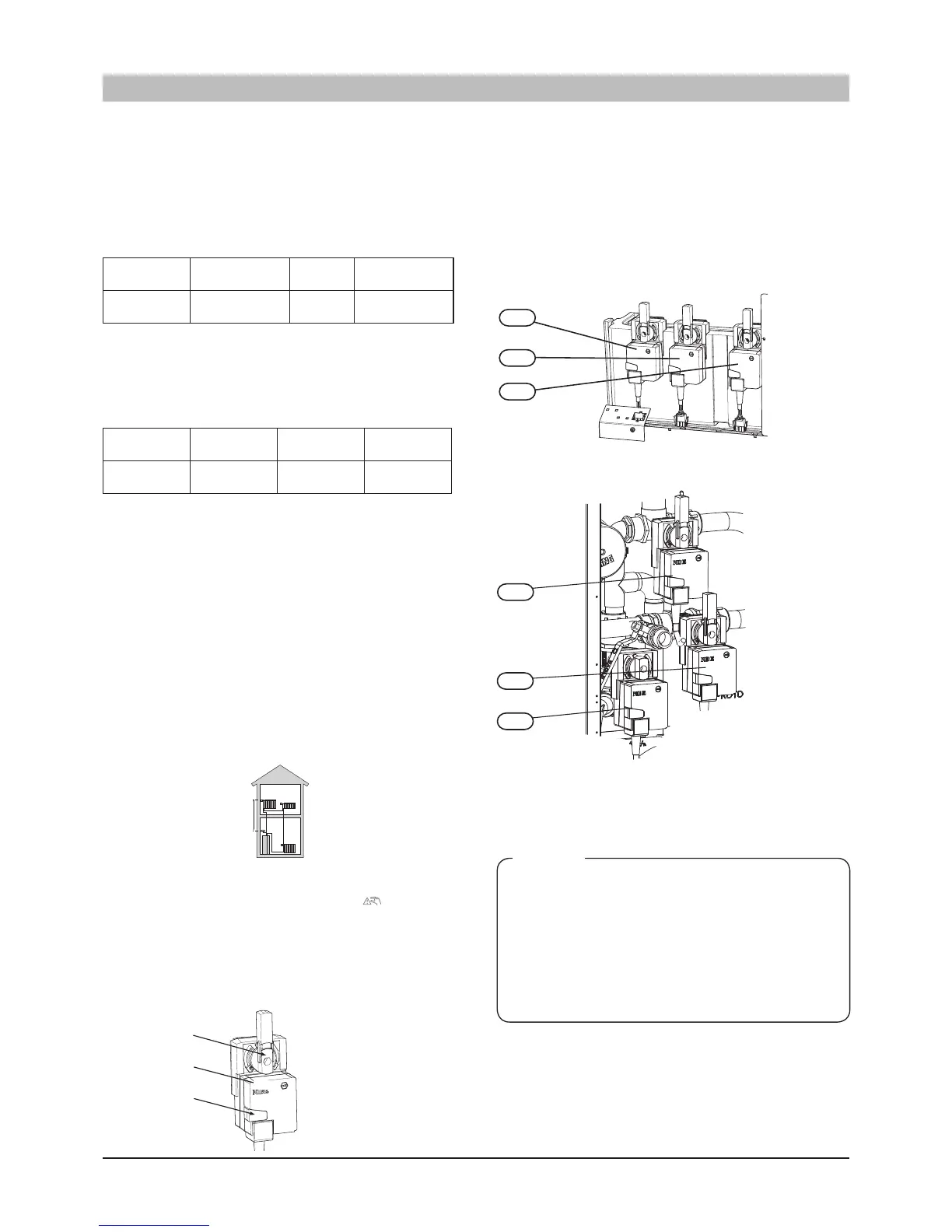

Manual shunting

When indoor unit is set to emergency mode on the main

switchSF1,theheatingcontrolsystemisnotinoperation,and

is why manual shunt operation is required.

1. Depress and lock the button on the valve.

2. Turn the mixing valve to the desired position by hand.

Loading...

Loading...