moog

MSD Servo Drive DC-AC Operation Manual

[]

Appendix

Technical data

79

Id.-No.: CA97554-001 Date: 06/2012

to glossaryto table of contents

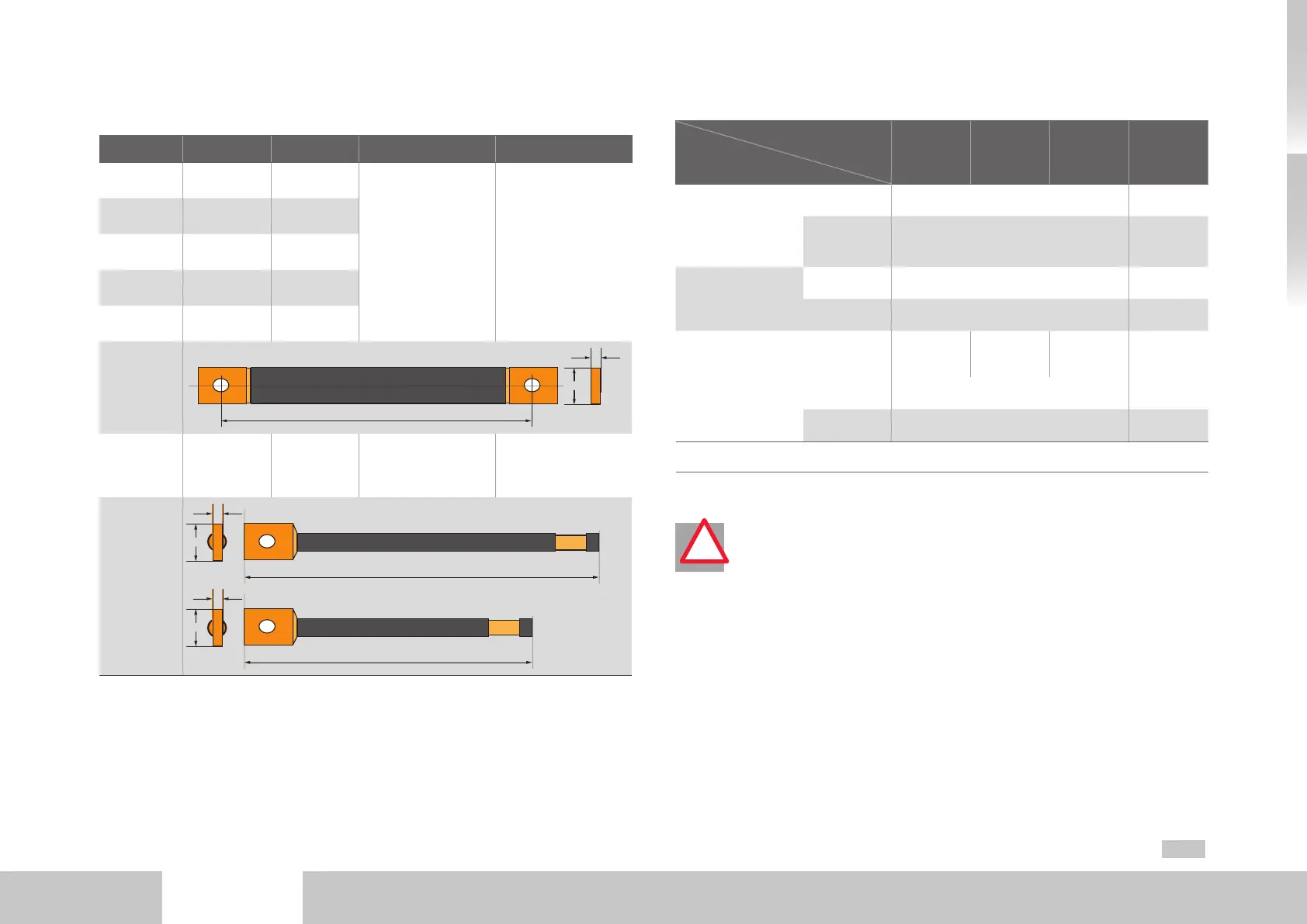

B.5 Ready made-up cables

Type L Cross-section Variant Connection

DC link

Size 1

61.5mm 42mm²

Flat copper braiding

with double shrink-fit

tube covering

Flat sheath on both

sides with hole

Ø 5.5mm

DC link

Size 2

93mm 42mm²

DC link

Size 3

133mm 42mm²

DC link

Size 4

174mm 42mm²

DC link

Size 5

193mm 42mm²

Sketch

L

4

15

DC link

Size 6A

L1 = 385mm

L2 = 345mm

30mm²

Round stranded

copper with double

shrink-fit tube covering

One side flat sheath

with hole Ø5.5mm,

second side stripped

strand

Sketch

L1

5

16

L2

5

16

Table B.16 Technical data – ready made-up encoder cables

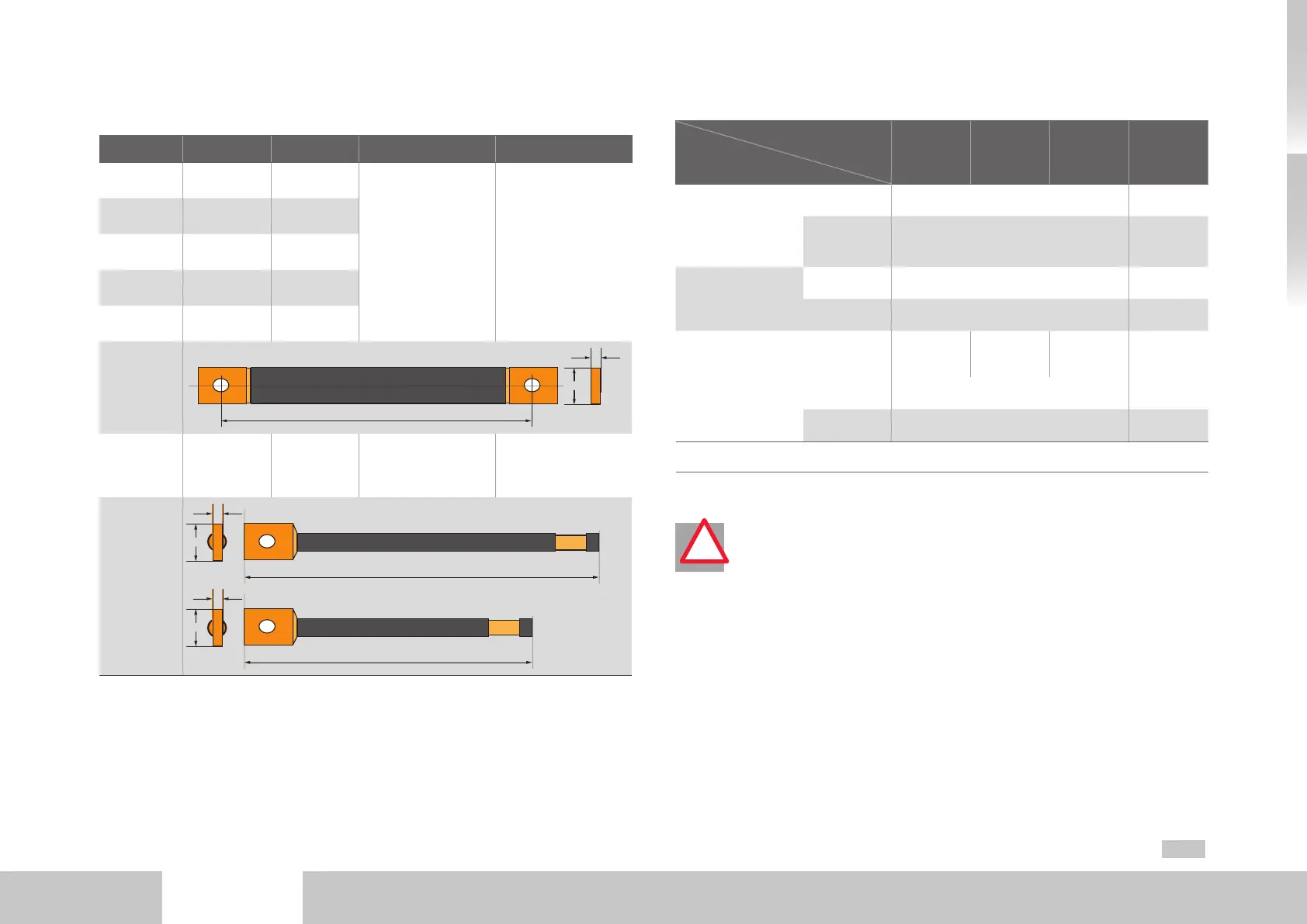

Cable connections

DC-AC servo drive

to connect

Supply

Size 1

Size 2

Size 3

Size 4

Size 5 Size 6A

Power supply unit

Size 5

or

DC-AC servo drive

Size 1 to Size 5

Cable

Use only the

ready made-up cables supplied.

-

Tightening

torque (Nm)

2.5 -

Power supply unit

Size 6A

Cable

Use only the

ready made-up cables supplied.

95mm²

(AWG4/0)

Tightening

torque (Nm)

2.5 20

AC-AC servo drive

Cable

6mm²

(AWG9),

max. 1m

16mm²

(AWG5),

max. 1m

35mm²

(AWG2)

95mm²

(AWG4/0)

On one side ring cable lug

1)

with hole Ø5.3mm.

Tightening

torque (Nm)

2.5 20

1) In the case of ring cable lugs without insulation, the crush zone and min. 20 mm of the cable insulation should be insu-

lated fully with heat-shrink tubing.

Table B.17 Cables, cross-sections and tightening torques

!

ATTEMTION! Requirements for longer cables

• Use only the ready made-up cables supplied for the DC electrical connec-

tions between the devices.

• If extending the cable is unavoidable (such as to bypass a switch cabinet

panel or for a second DC-AC servo drive array), the DC link connection

must be made as follows:

− Cable cross-section >30mm² (copperr)

− A PE conductor of the same cross-section should run alongside and be

connected to the PE terminals of the two interconnected devices.

− The three conductors (DC+, DC-, PE) should be bundled and shielded.

− A length of 2 metres must not be exceeded.

− Only one extension may be executed in each multi-axis system.

Loading...

Loading...