moog

MSD Servo Drive DC-AC Operation Manual

14

Id.-No.: CA97554-001 Date: 06/2012

to glossaryto table of contents

2.3 DC-AC servo drive installation

Liquid-cooled housing

Step Action Comments

Arrange the devices starting from the

supply unit to the right and/or left sorted in

descending order of power output, in order to

minimize thermal influences.

In the case of the power supply unit Size 5,

align all DC-AC servo drives in a line along the

top edge of the unit (Fig. 2.5).

In the case of the power supply unit Size 6A,

align all DC-AC servo drives 18.5 mm lower

(Fig. 2.6).

This is necessary in order to

execute the DC link using the

ready made-up cables.

For specified mounting clearances

see Table 2.1.

Mark out the positions of the tapped holes

and the pipe socket on the backing plate.

Drill holes and cut a thread for each fixing

screw in the backing plate.

Take account of the bend radius

of the connecting cables!

For hole pitch and dimensional

drawings see Table 2.2, Fig. 2.3

and Fig. 2.4.

Mount the DC-AC servo drives vertically in a

row on the back plane.

The contact area must be

metallically bright. For the DC

power supply use the supplied

ready made-up DC link cables.

When fitting the hose connections (not

supplied) in the pipe sockets, brace with

a 22mm open-ended wrench in order to

prevent damage to the device by torsion.

Ensure a perfect liquid-tight

connection (e.g. using a Teflon

sealing strip)!

Continue with the electrical installation in

section3

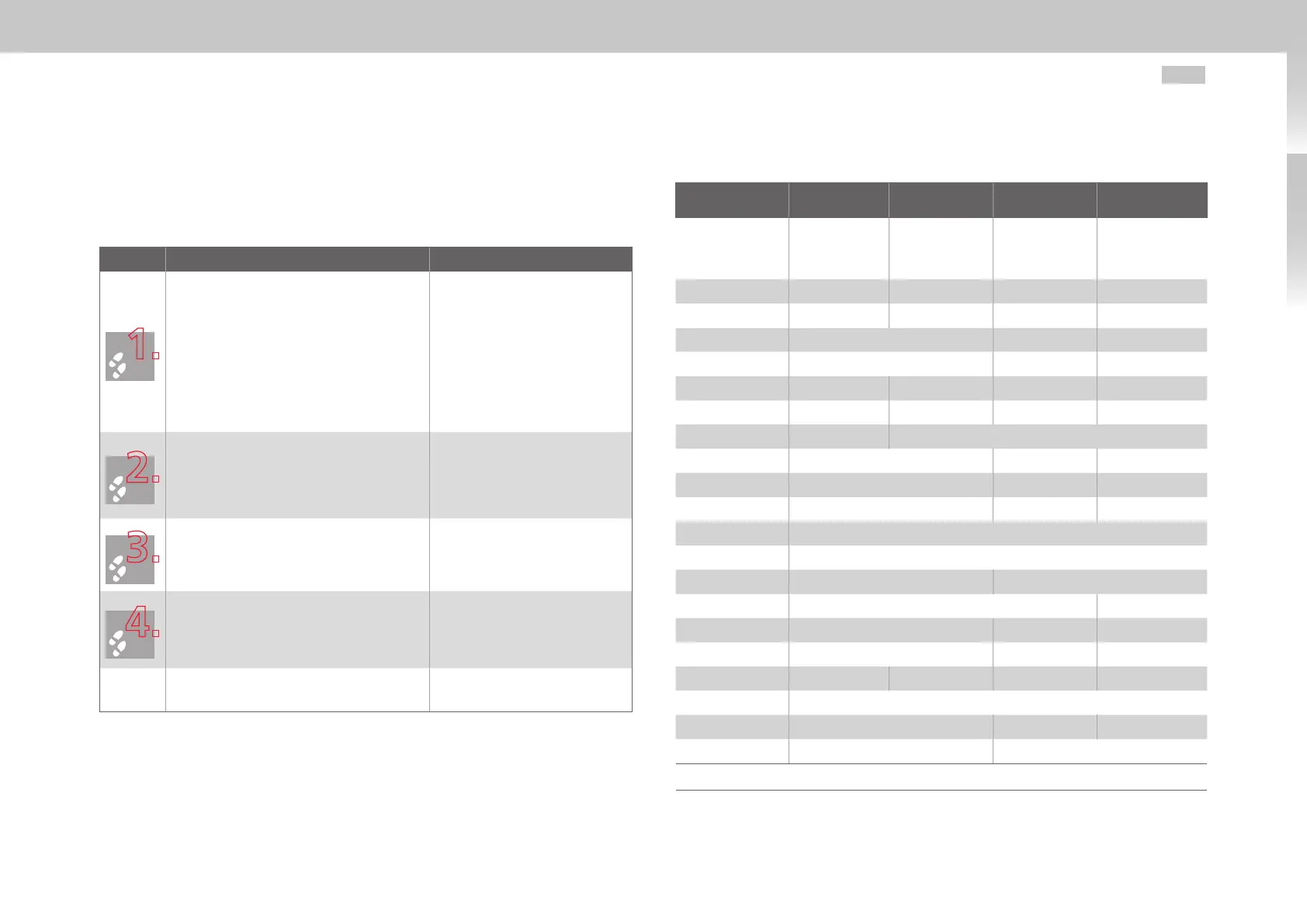

Dimensions and mounting distances for liquid-cooled housing

MSD Servo Drive Size 3 Size 4 Size 5 Size 6A

G397-020

G397-025

G397-026

G397-035

G397-053

G397-070

G397-084

G397-110

G397-143

G397-170

G397-210

Weight [kg] 6.5 7.5 13 32

B (width) 130 171 190 280

H (height)

1)

295 346.5 540

T (depth)

1)

224 238.5 285

A 80 120 150 200

A1 10 25 40 65

A2 60 70

C 382 406.5 581

C1 5 6 10

D 4.8 6.5 9.5

D1 48 (hole for pipe-socket)

E Direct side by side mounting, maximum 2

F

2)

≥150 ≥180

G

2)

≥300 ≥500

H1 392 418.5 600

H2 38.5 15 20

H3 75 70 54 56.5

S [inches] 3/8 (inside thread)

Screws 4 x M4 4 x M6 4 x M8

T1 74 73.5

1) Without terminals/connectors All dimensions in mm

2) The bend radius of the connecting cables must be taken into account

Table 2.2 Dimensions and mounting distances for liquid-cooled housing

Loading...

Loading...