moog

MSD Servo Drive DC-AC Operation Manual

30

Id.-No.: CA97554-001 Date: 06/2012

to glossaryto table of contents

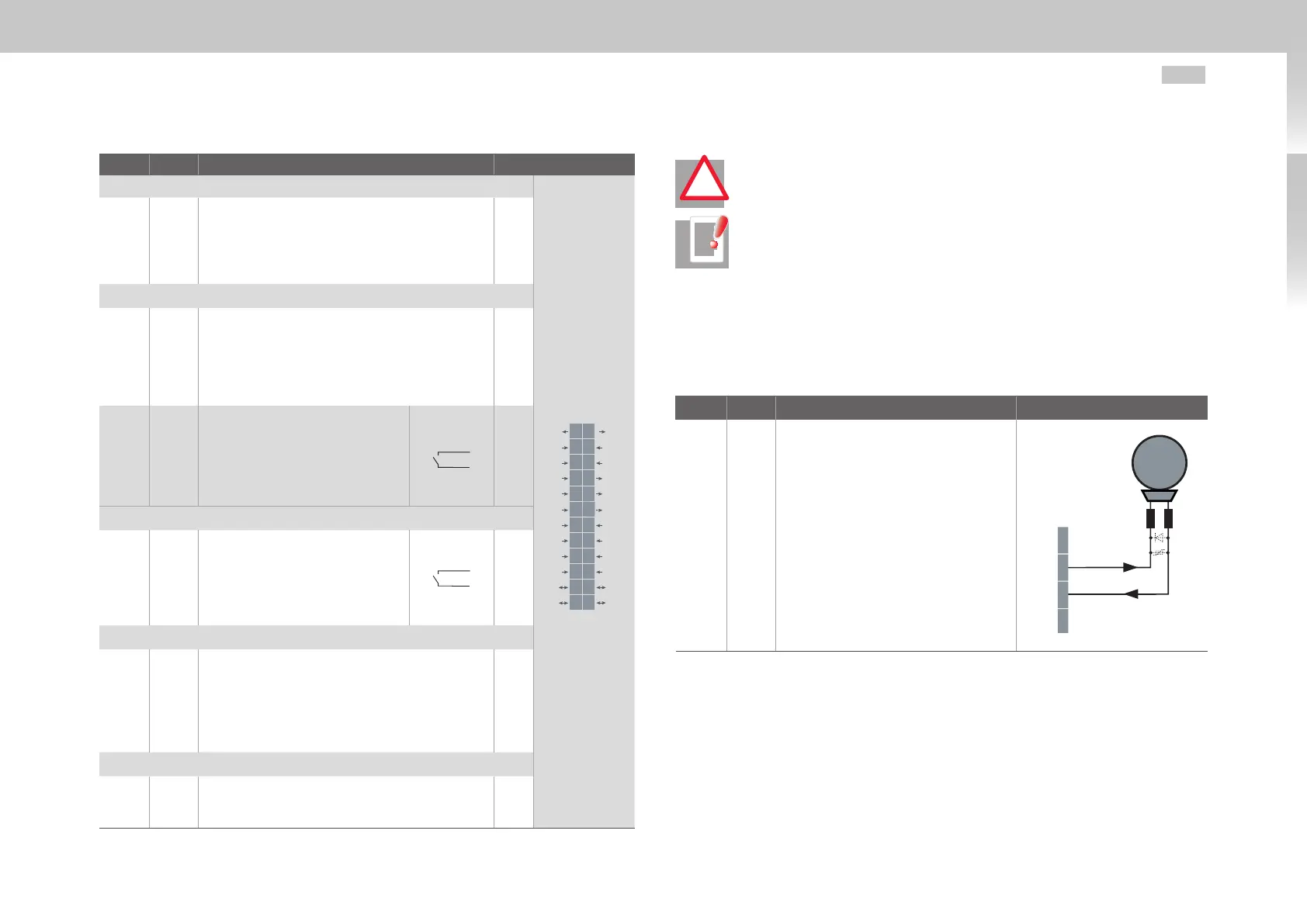

Des. Term. Specification Isolation

Digital outputs

REL

REL

ISDSH

ISD06

ISD05

ISD04

ISD03

ISD02

ISD01

ISD00

+24V

DGND

RSH

RSH

ENPO

OSD02

OSD01

OSD00

ISA1-

ISA1+

ISA0-

ISA0+

+24V

DGND

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

OSD00

OSD01

OSD02

X4/7

X4/8

X4/9

• No destruction in case of short-circuit (+24V ->

GND), but device may briefly shut down

• I

MAX

=50mA, PLC-compatible

• Terminal scan cycle =1ms

• High-side driver

yes

STO (Safe Torque Off)

ISDSH

(STO)

X4/22

• "Request input" = Low-level

• OSSD-capable (from hardware version 2)

• Switching level Low/High: ≤4.8V / ≥18V

• U

IN max

= +24VDC +20%

• I

IN

at +24VDC = typ. 3mA

yes

RSH

RSH

X4 /11

X4/12

Diagnosis STO, both tripping chan-

nels active, one NO contact with au-

tomatically resetting circuit-breaker

(polyswitch)

• 25V/200mAAC, cosϕ=1

• 30V/200mADC, cosϕ=1

X4/12

X4/11

yes

Relay outputs

REL

X4/23

X4/24

Relay, 1 NO contact

• 25V/1.0AAC, cosϕ=1

• 30V/1.0ADC, cosϕ=1

• Switching delay approx.10ms

• Cycle time1ms

X4/23

X4/24

Auxiliary voltage

+24V

X4/2

X4/14

• Auxiliary voltage to feed the digital control inputs

• U

H

= U

V

-∆U (∆U typically approx.1.2V), no de-

struction in case of shot-circuit (+24V -> GND),

but device may briefly shut down.

• I

MAX

=80mA (per pin) with self-resetting circuit-

breaker (polyswitch)

yes

Digital ground

DGND

X4/1

X4/13

Reference ground for +24V, I

MAX

=80mA (per pin),

Hardware versions 0..1 with self-resetting circuit-

breaker (polyswitch)

yes

Table 3.4 Specification of control connections X4

ATTENTION! With high currents flowing through the ground terminals a high

resistance isolation from the device ground is required. This may cause incor-

rect response of the drive (avoid ring currents in the wiring).

NOTE: Note that in the event of a fault the supply unit may no longer be able

to feed regenerative power from the DC-AC servo drives back into the grid.

In order to prevent destruction of the supply unit braking resistor in sustained

regenerative mode, the DC-AC servo drives and power supply unit can be

mutually locked via X4. For more information and an example of circuit con-

figuration refer to appendix on page 83.

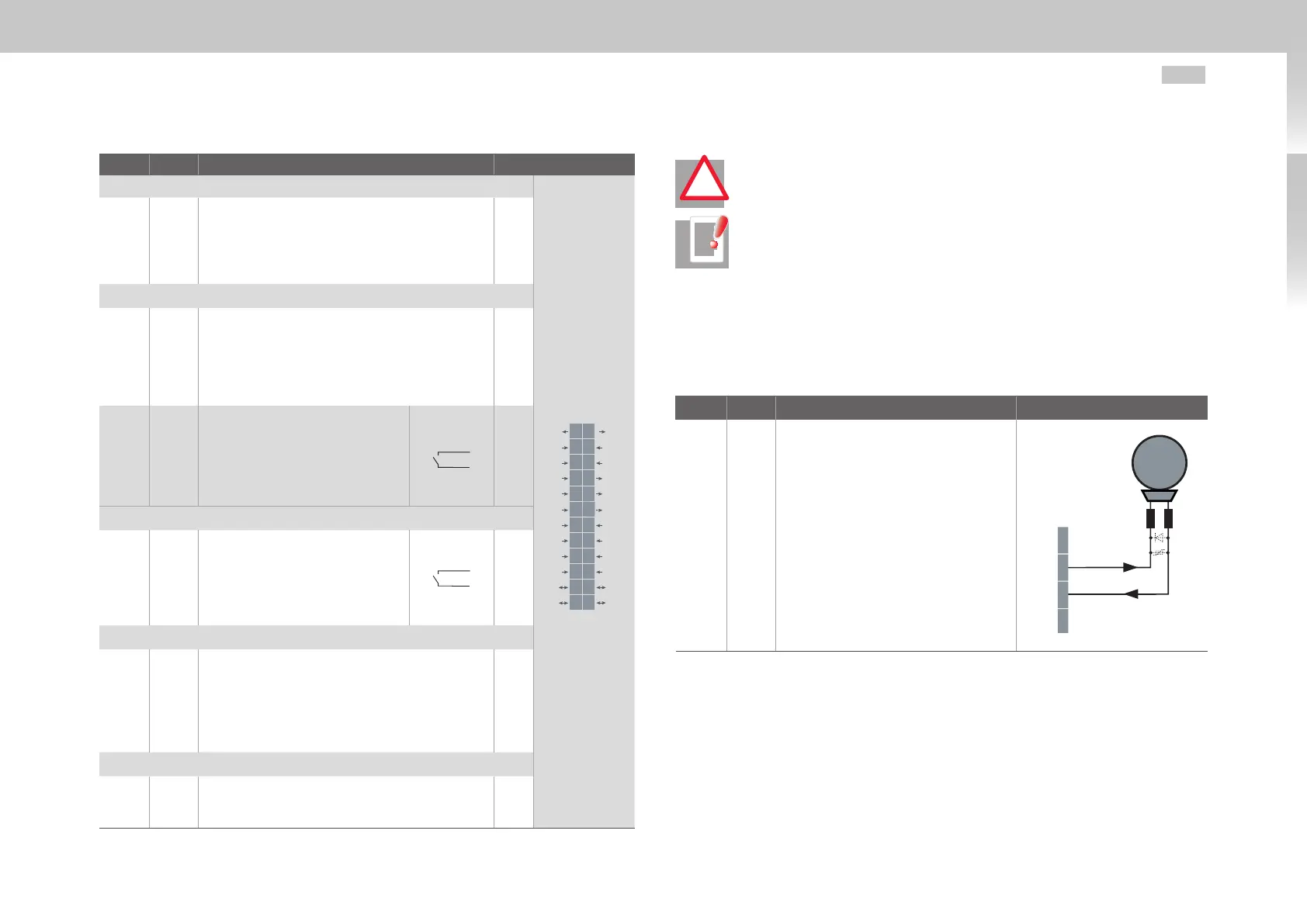

3.7.2 Brake driver

Connector X13 (Size 1 to Size 4) is intended for connection of a motor brake.

Des. Term. Specification Connection

+24V

BR+

BR-

GND

X13/1

X13/2

X13/3

X13/4

• Short-circuit-proof

• Voltage supply is via the control supply

U

V

on X9 or X10

• U

BR

=U

V

-∆U`(∆U`typically ap-

prox.1.4V)

• To actuate a motor holding brake up

to I

BR

=2.0Amax., for brakes with

higher current requirements a relay

must be interposed.

• Overcurrent causes shutdown

• Also usable as configurable digital

output.

• Interruptible cable break monitoring

<500mA in condition "1" (up to relay)

M

Brake (+)

Brake (-)

X13

1

BR+ 2

BR- 3

4

Table 3.5 Specification of terminal connections X13

!

Loading...

Loading...