Instructions

Page 103

Column 1

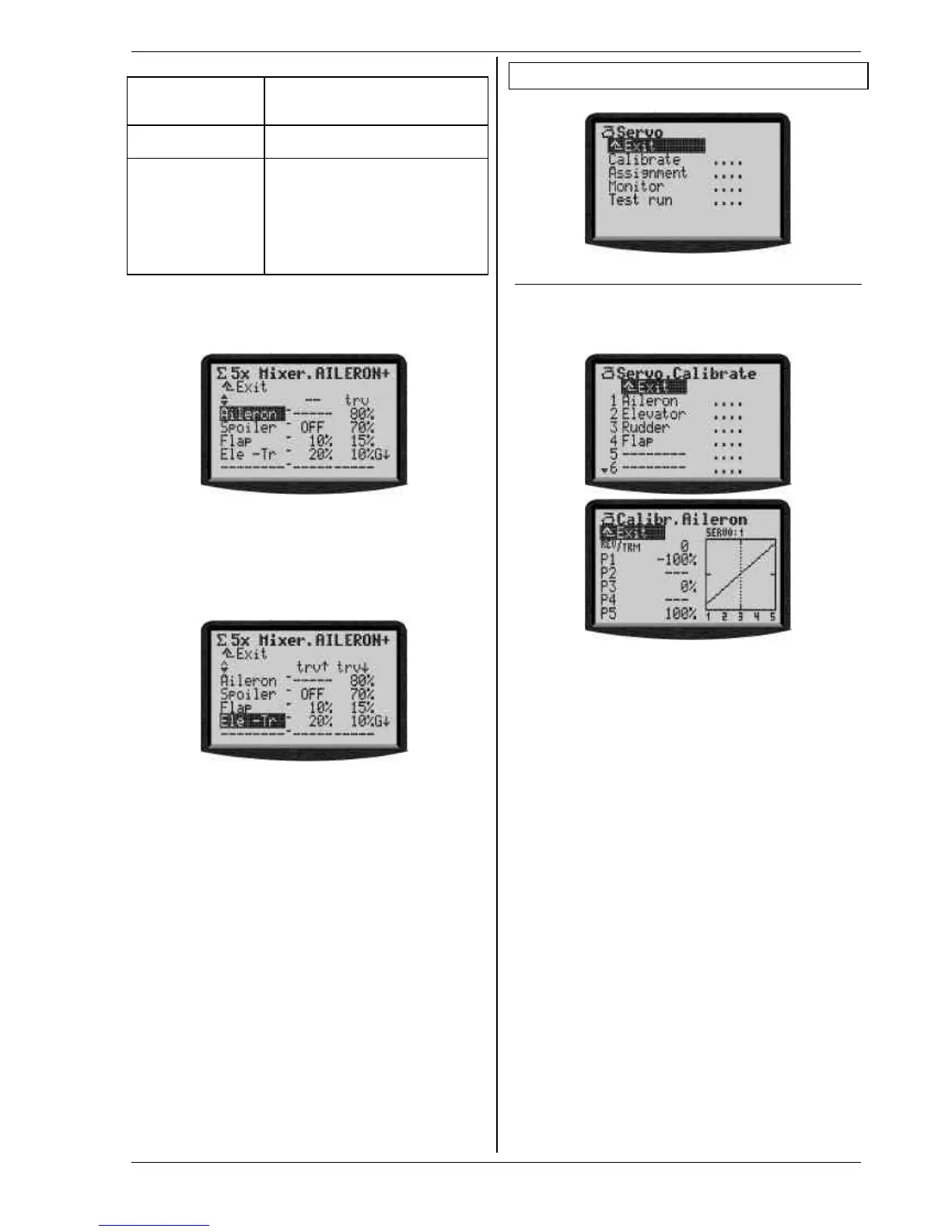

(above input)

Shows the mixer option assigned

to the mixer input in the form of a

symbol (è 13.2.3)

Column 2+3 Show the type and effect of the

mixer values.

Column 4 Indicates whether the mixer input

can be switched off; if so, which

switch is used, and the current

switch status:

Asterisk * mixer input = ON

Arrow shows ON position of

switch (if input is OFF)

Example:

The input (transmitter control) Aileron (primary input)

affects the aileron servo(s) symmetrically relative to the

servo centre, with a travel setting of 80%.

Example:

The input (transmitter control) Ele -Tr (Elevator, no trim)

affects the aileron servo(s) asymmetrically relative to the

servo centre (snap-flap). The travel setting is 30% in one

direction, 20% in the other. The mixer input can be

switched off using switch G. The current switch status is

ON (asterisk *), i.e. the input is activated.

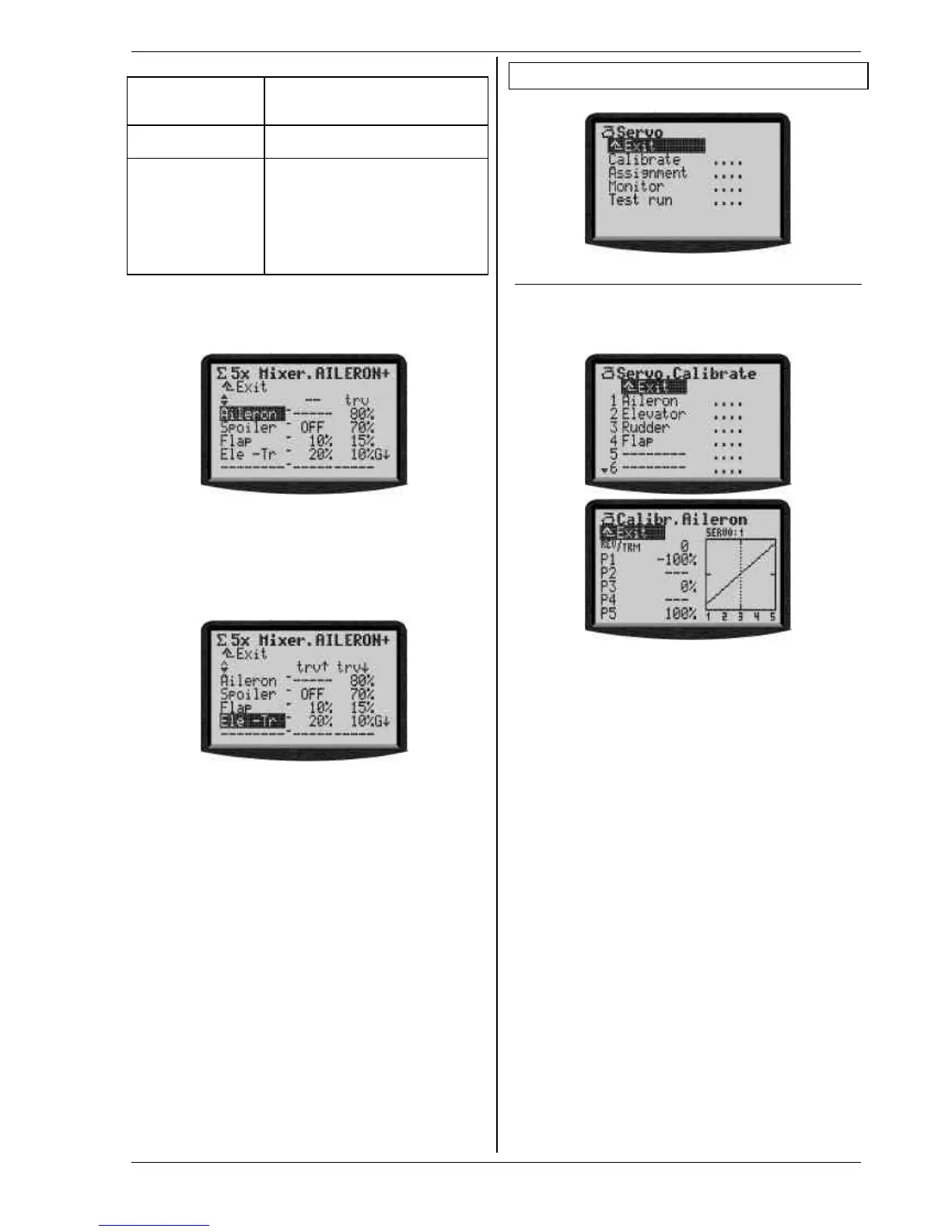

16. Main menu „Servo“ KK

I affects active model memory

16.1. Sub-menu „Calibrate“

In “Calibrate” you can adjust the travels, centres and - if

required - intermediate points for all servos, to ensure

that the servos move identically and evenly, and reach

the required end travels.

All changes to the parameters REV/TRM and the servo

calibration points P1 ... P5 are shown immediately in the

graph, making it easy to understand the effect of the

changes you make.

Line 1 always displays the name (function) of the servo.

The channel number (receiver output) of the selected

servo is shown above the graph.

Below the graph (X-axis) the numbers 1 ... 5 correspond

to the servo calibration points P1 ... P5.

16.1.1. Parameter „REV/TRM“

The first parameter REV/TRM has two functions:

1. Servo reverse (REV) changes the

direction of rotation

2. Servo trim (TRM)

Servo reverse REV

To reverse the direction of servo rotation simply select

the parameter value and press the REV/CLR-button:

⇒ the curve is “reversed”

⇒ the prefix changes

(only if the value of the parameter TRM ≠ 0)

Servo trim TRM

Servo trim is used to compensate for variations from the

nominal neutral position of one control surface. A cor-

rection may be necessary with servos, for example,

which do not feature adequate temperature compensa-

tion, and whose neutral position tends to vary.

The value for TRM operates on the standard trim princi-

ple, i.e. the set trim value works as an offset on all cali-

bration points P1 ... P5, thereby effecting a parallel shift

Loading...

Loading...