POSICON positioning control – Supplementary manual for series SK 200E and SK 250E-FDS

34 BU 0210 en-3117

Pos: 14 4 /Anlei tung en/El ektr onik/P OSICON /4. Funkti onsbes chr eibung/ Wego ptimal e Posi tioni erung _Ergä nzung _01 _Beispi el für ei ne Singleturnanwendung @ 14\mod_1478169580383_388.docx @ 2301069 @ 5 @ 1

Examples for a "single-turn application"

The calculation of the overflow point of a single-turn application is made according to the following

equation:

±n

max

= 0.5 * Ü

b

/ U

n

n

max

: Number of revolutions of motor = Overflow point

(P615)

Ü

b

: Speed ratio

(P607 [-xx])

U

n

: Reduction ratio

(P608 [-xx])

)

Depending on the encoder or absolute encoder used for positioning control: [-xx] = [-02]

Example 1

The encoder, an absolute encoder, is mounted on the motor shaft (speed and reduction ratio = "1").

±n

max

= 0.5 * 1 / 1 = 0.5 revolutions

The following values are parameterised:

= 1

P608 [-02]

= 1

=

= 0.5

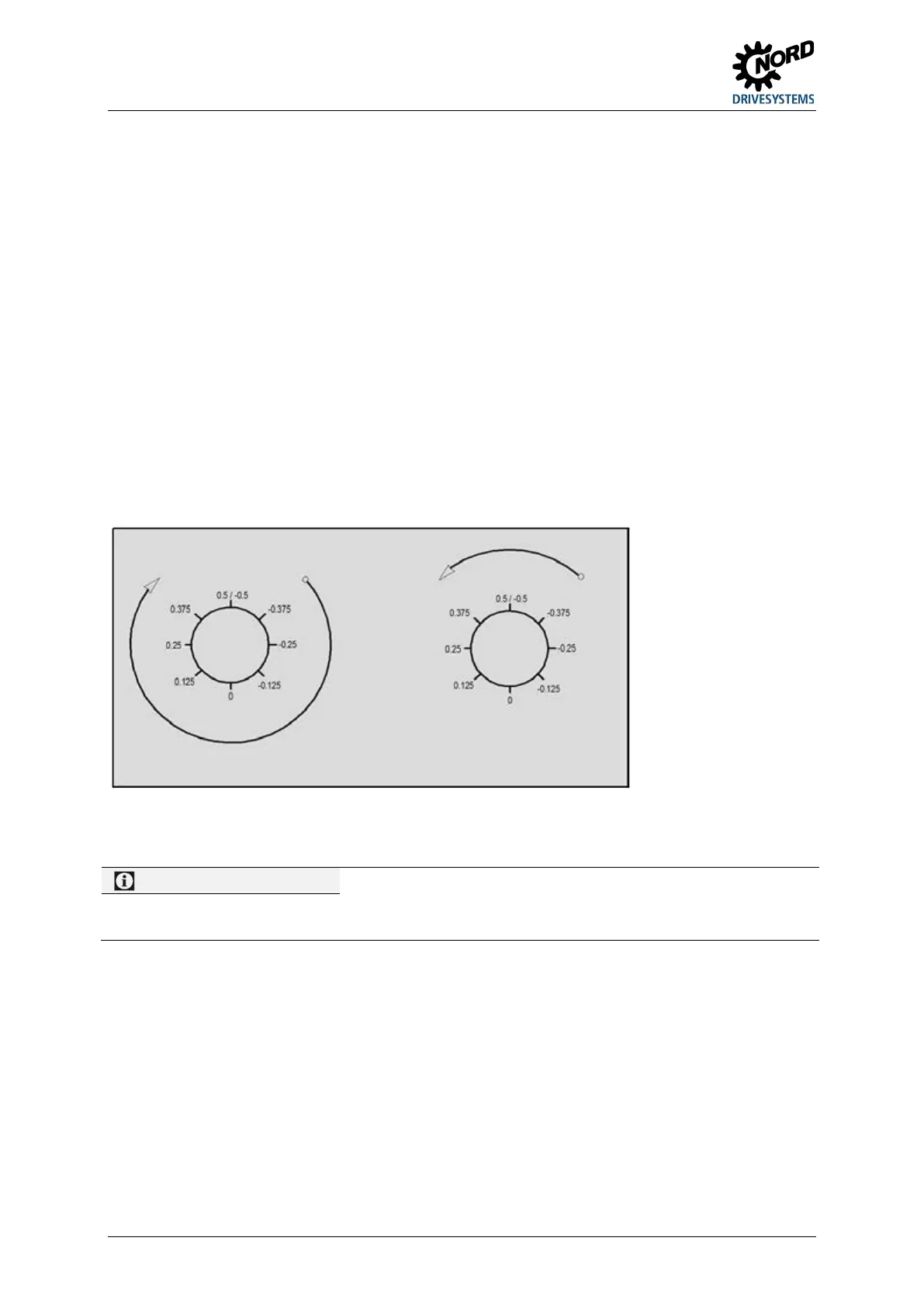

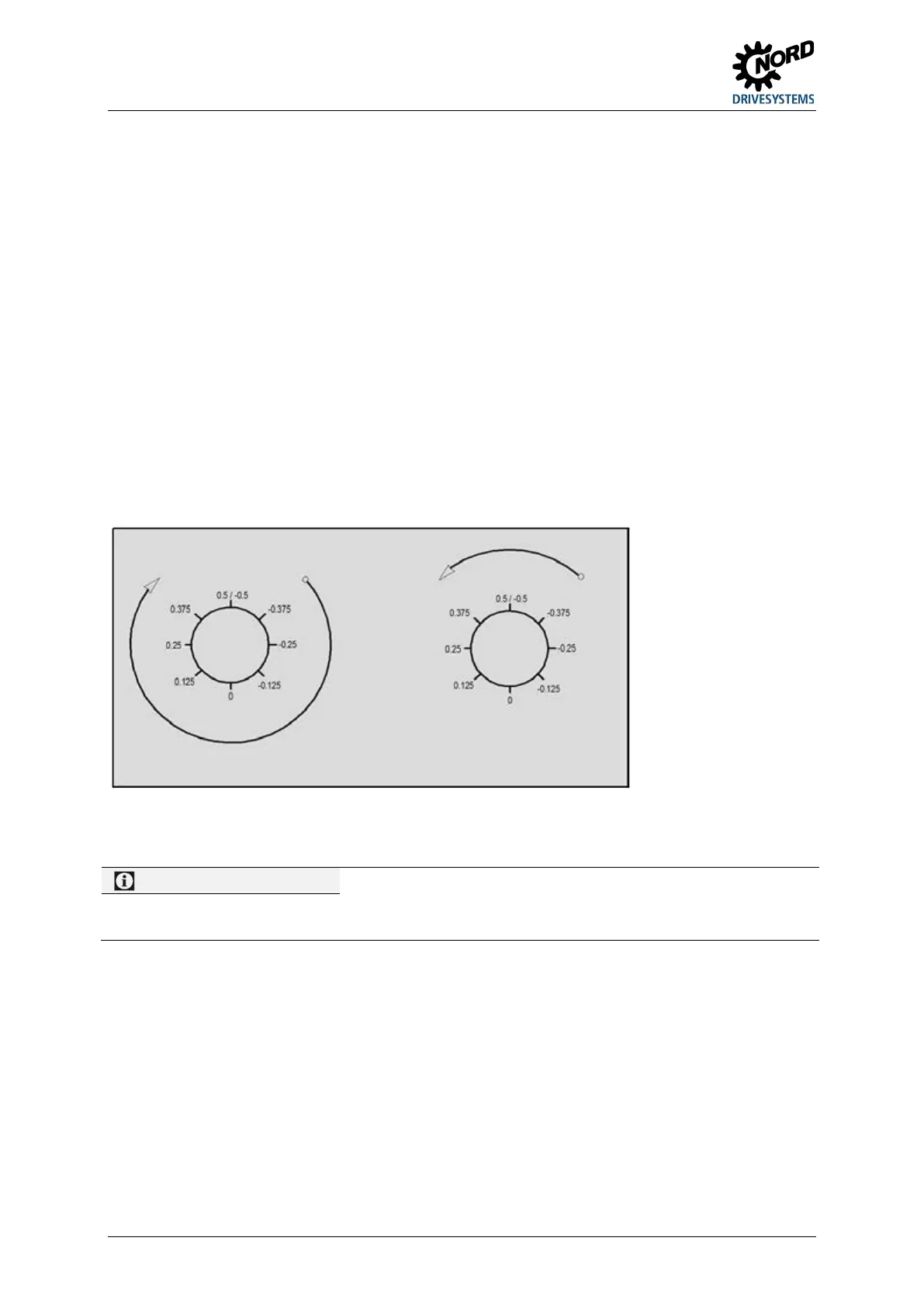

Linear path Path optimised movement

Figure 1: Rotary platform positioning with a single-turn application

In this case (single-turn application, encoder on the motor shaft) P615 can also remain in the factory setting

(setting 0).

Example 2

The encoder, an absolute encoder is installed on the output side of the gear unit. The gear unit has a

speed ratio of i = 26.3.

±n

max

= 0.5 * 263 / 10 = 13.15 revolutions

The following values are parameterised:

P607 [-02]

= 263

= 10

P615 =

= 13.15

Pos: 14 5 /Allg emein/ Allg emeing ültig e Mod ule/---------Sei tenumbr uch ko mpakt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

Loading...

Loading...