POSICON positioning control – Supplementary manual for series SK 200E and SK 250E-FDS

76 BU 0210 en-3117

Pos: 33 8 /Anlei tung en/El ektr onik/P OSICON /7. Störung smel dung en/FA Q Betri ebsst örunge n @ 14\mod_1478872151653_388.docx @ 2303450 @ 2 @ 1

7.2 FAQ operational problems

Typical operating errors and sources of error in connection with positioning and speed control are

listed below. It is recommended that the same sequence as for commissioning is used for

troubleshooting. Accordingly, it should first be checked whether the affected axis is running without

control. After this, the speed and position controllers should be tested.

Pos: 33 9 /Anlei tung en/El ektr onik/P OSICON /7. Störung smel dung en/FA Q Betri ebsst örunge n_01_ Betr ieb mit Dr ehza hlrüc kführ ung, ohn e Lager egel ung @ 14\ mod_1478872439200_388.docx @ 2303486 @ 3 @ 1

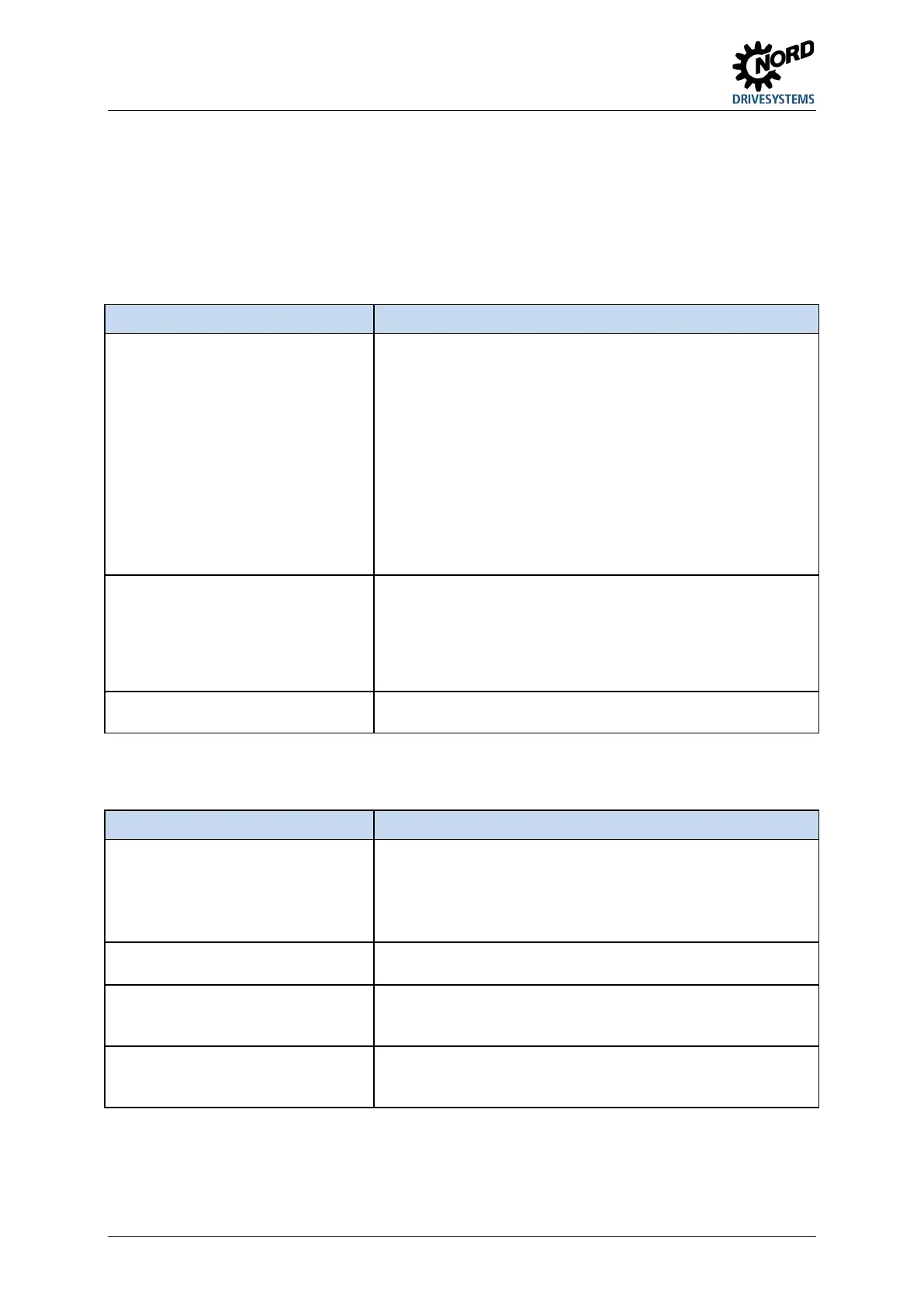

7.2.1 Operation with speed feedback, without position control

Symptom Cause

• Motor only rotates slowly

• Motor runs unevenly

• Incorrect assignment of the direction of rotation of the motor to the

counting direction of the incremental encoder

– Change the sign in P301

• Incorrect incremental encoder type (no RS422 outputs)

• Encoder cable interrupted

– Check the voltage difference of track A and B with P709

• Encoder voltage supply missing

• Incorrect pulse number parameterised

– Check the resolution in P301

• Incorrect motor parameters

– Check P200 et seq.

• Encoder track missing

• With active speed feedback (servo

mode enabled) the motor runs

correctly, but runs unevenly at low

speeds

• Overcurrent switch-off at higher

speeds

• Incremental encoder incorrectly mounted

• Interference in encoder signals

• Overcurrent switch-off when braking

• For field weakening operation in servo mode, the torque limit must

not exceed 200 %

Pos: 34 0 /Anlei tung en/El ektr onik/P OSICON /7. Störung smel dung en/FA Q Betri ebsst örunge n_02_ Betr ieb mit a ktiver L agereg elu ng @ 14\mod_1478873517240_388.docx @ 2303522 @ 3 @ 1

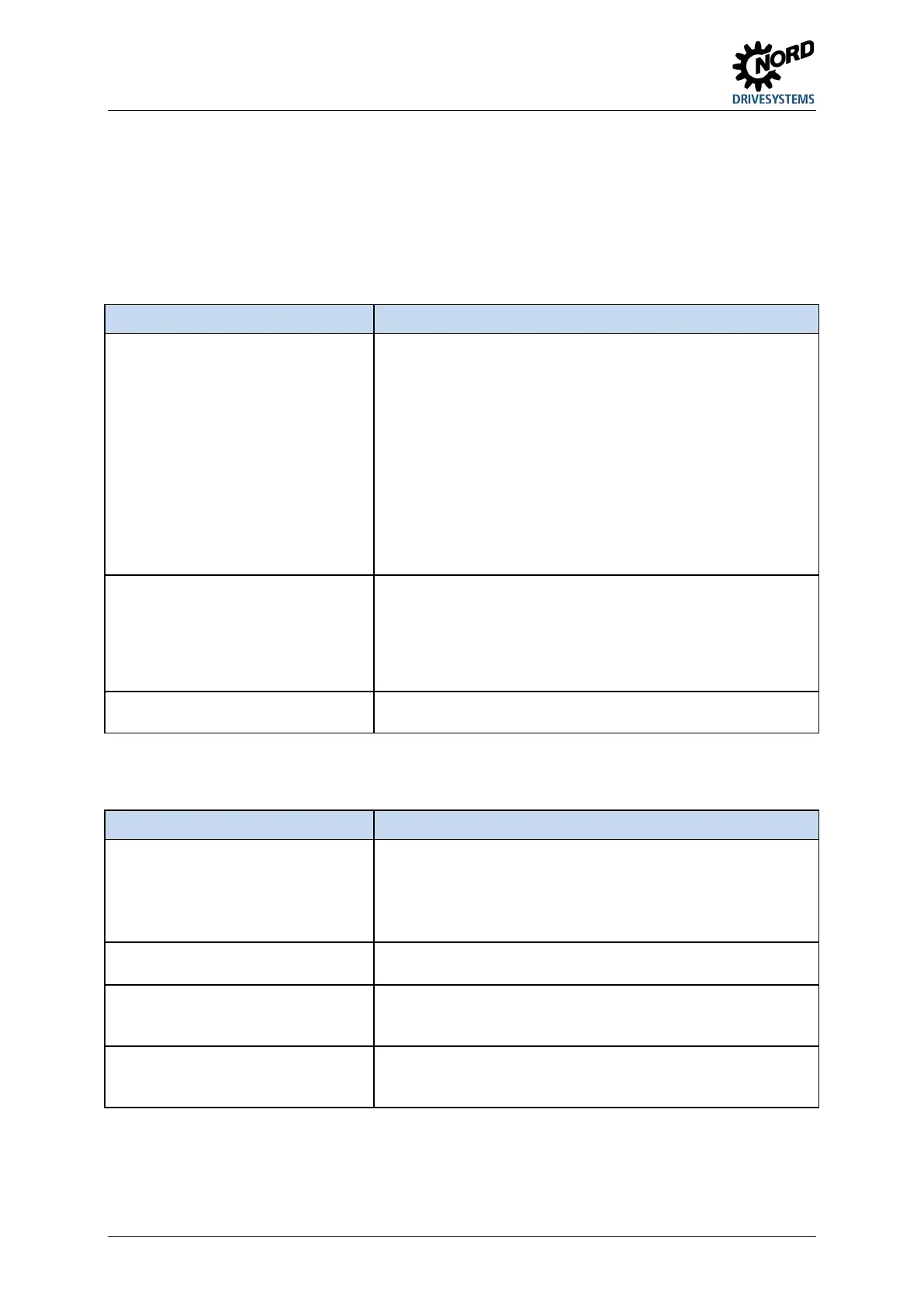

7.2.2 Operation with active position control

Symptom Cause

• Target position exceeded

• Position control P amplification considerably too large

– Check P611

• Speed controller (servo mode) not optimally set

– Set I amplification to approx. 3 % / ms,

– Set P amplification to approx. 120 %

• Drive oscillates at the target position

• Position control P amplification considerably too large

– Check P611

• Drive moves in the wrong direction

(away from the setpoint position)

• The direction of rotation of the absolute encoder does not match

the direction of rotation of the motor

– Parameterise a negative value for the speed ratio (P607)

• Drive unit sags away after enabling is

removed (lifting gear)

• Setpoint delay missing (control parameter)

• For servo mode = "Off" the control must be locked immediately by

the event "End Point Reached"

Pos: 34 1 /Allgemein/Allgemeingültige Module/---------Seitenu mbruc h komp akt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

Loading...

Loading...