17

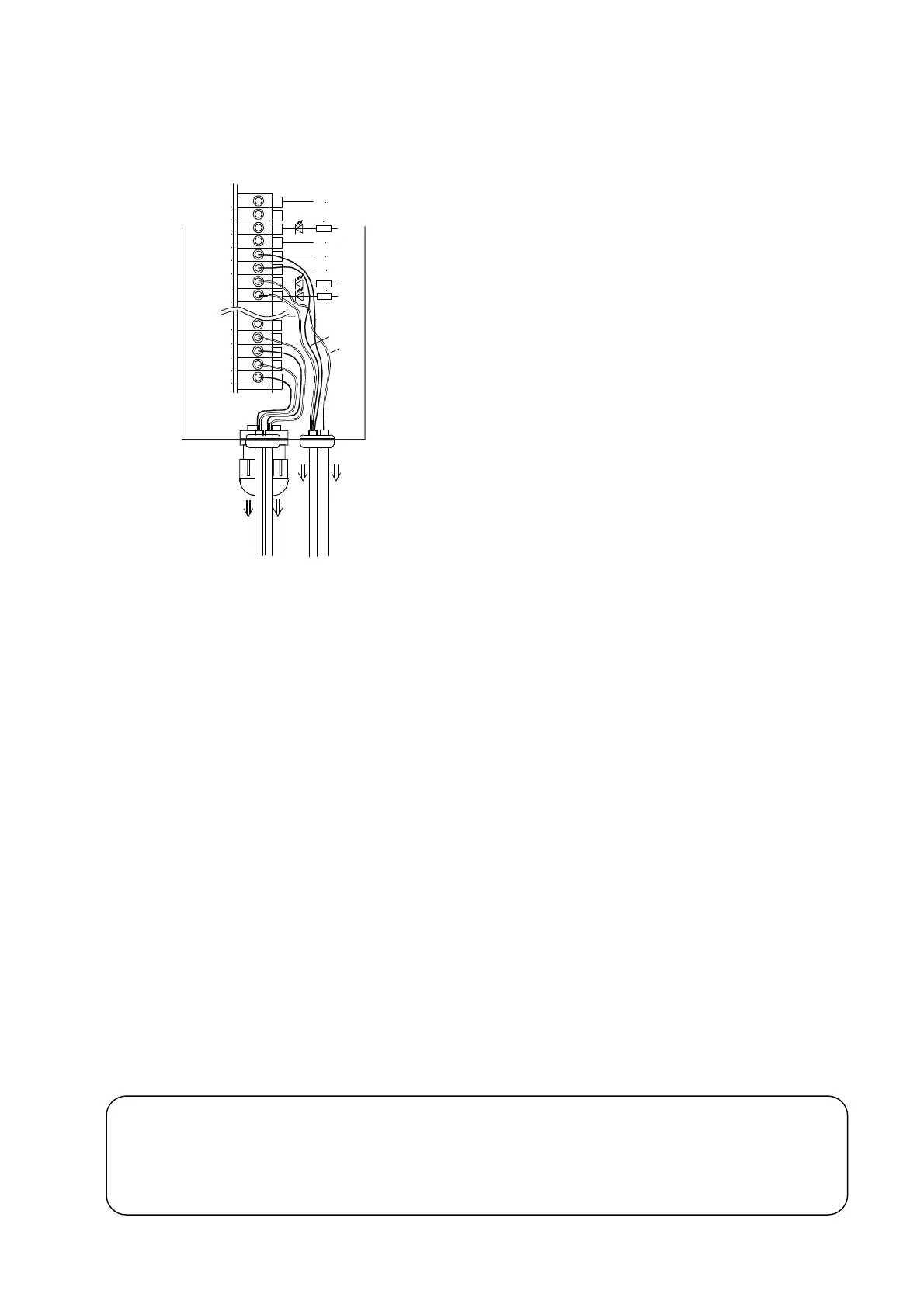

4. Two rows AND air overflow control by two sensors

(In case that overflow is controlled by air)

When discharging with two rows by the parts feeder, in case of

using the air for discharging the work due to overflowing, the

overflow control for each row with use of air becomes possible by

installing two sensors for overflow and setting the function H00 to 4

or 5.

The signal of sensor 1 is processed at set time of ON/OFF delay

timer 1, and output to the terminal P1, and the work is discharged

by the air at the time of full work. The signal of sensor 2 is

processed at set time of ON/OFF delay timer 2, and output to the

terminal P2, and the work is discharged by the air at the time of full

work. The parts feeder is stopped, and the air is turned off for the

case of both sensor 1 side and sensor side 2 being full.

Be careful that the total current consumption of the sensor and

the solenoid valve does not exceed the capacity (200mA) of

controller's service power supply. The terminal P0 can be used for

ON/OFF of supplementary air during driving while using the

terminals P1 and P2.

The configuration and the switching capacity of the drive circuit

of P1 and P2 terminals are the same as those of the terminal P0

(Refer to P.16).

Other notes for the connection are also the same as for the

terminal P0.

When the solenoid valve is not connected, it is possible to use it as two rows AND overflow control in the

paragraph 5 (1) below. In this case, although a logic reversing of each input becomes possible, because the

timer is added for each, it is necessary to set the time of timer for both 1 and 2 of ON/OFF Delay.

5. Other controls by sensor and solenoid valve

In addition to 1~4 explained above, the following controls are possible.

(1) To stop the parts feeder with the two rows AND overflow by using two sensors in case of discharging

two rows by the parts feeder. (In case that air is not used for the overflow control)

(2) In case that one row is discharged on the chute, overflow sensor is fitted respectively to chute inlet

and outlet, then when the work exists, the sensor at the chute inlet turns the parts feeder OFF, and

when the work does not exist, the sensor at the chute outlet turns the parts feeder ON.

(3) The overflow sensor on the chute outputs this sensor signal to the terminal P2 as well as controlling

the normal overflow (branching of signal).

(4) The overflow sensor controls the normal overflow and also outputs the jam signal to the terminal P2

when the work is not detected for a certain time. It can be used for jam air blow control of NTN

spring separate feeder.

※ As for the air overflow control (NTN internal nominal designation) explained on P.16~17, the behavio

becomes rather complicated. When you are already well aware of the content, it is possible to cover the wide

range control by using these functions. Please contact NTN for the detail or obtain separately the control

manual for confirmation.

バルブ2へ

24V

+V

X1

0V

24V

0V

IN1

IN2

+24V

0V

0V

+24V

赤

黒

24V

P1

24V

センサ1へ

茶

黒

青

P2

センサ2へ

バルブ1へ

P0

黒

3.3k

3.3k

3.3k

Black

Brow

Black

Red

Blue

Black

To sensor 2

To valve1

To sensor 1

To valve 2

Loading...

Loading...