Outline of Control PACD011001C2

440 Function UM Combination “MA1R Series” Using R-407C

3.1.13 Discharge Pipe Temperature Control

Controls the liquid injection and operating frequency to prevent abnormal increase of discharge pipe

temperature and compressor internal temperature.

Liquid Injection

Control (Inverter

Compressor)

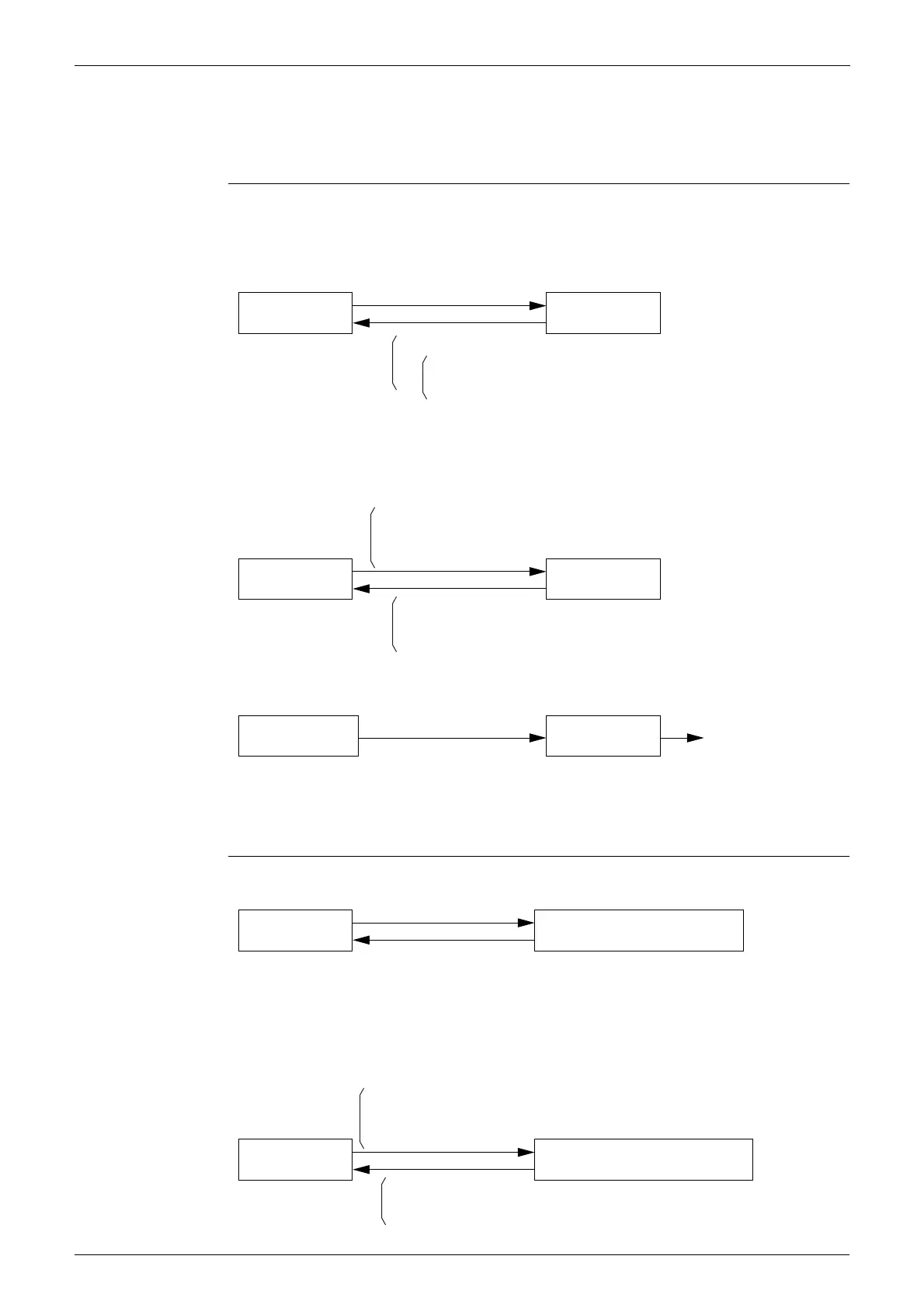

„

Opens SVTi (Y3S) (solenoid valve for inverter compressor liquid injection) for 3 minutes after

software startup.

[Cooling]

DSHi: Inverter compressor discharge pipe superheated degree

= Tdi (Th3-1) - (HP equivalent saturation temperature)

Tdi: Inverter compressor discharge pipe temperature (Th3-1)

[Heating]

[Preparing Oil return and defrosting operation (1 min before operation start)]

[Oil return operation/defrosting operation]

„

SVTi (Y3S) is OFF at any case when inverter compressor stops.

Liquid Injection

Control (STD

Compressor)

[In cooling operation]

DSHs: STD compressor discharge pipe superheated degree

= Tds1, 2 (Th3-2) - (HP equivalent saturation temperature)

Tds1, 2 : STD compressor discharge pipe temperature (Th3-2)

[In heating operation]

Normal operation SVTi : ON

DSHi≥40˚C

DSHi<15˚C

(V0826)

OR

&

DSHi<25˚C

10min elapsed

Normal operation SVTi : ON

• Tdi≥100˚C

• LP<0.05MPa

• (HP+0.10) / (LP+0.10)>8

• Tdi<90˚C

• LP>0.07MPa

• 2 min elapsed

(V0827)

OR

&

Preparing oil return

and defrosting

SVTi : ON

DSHi≥15˚C

Start oil return

& Defrost operation

(V0828)

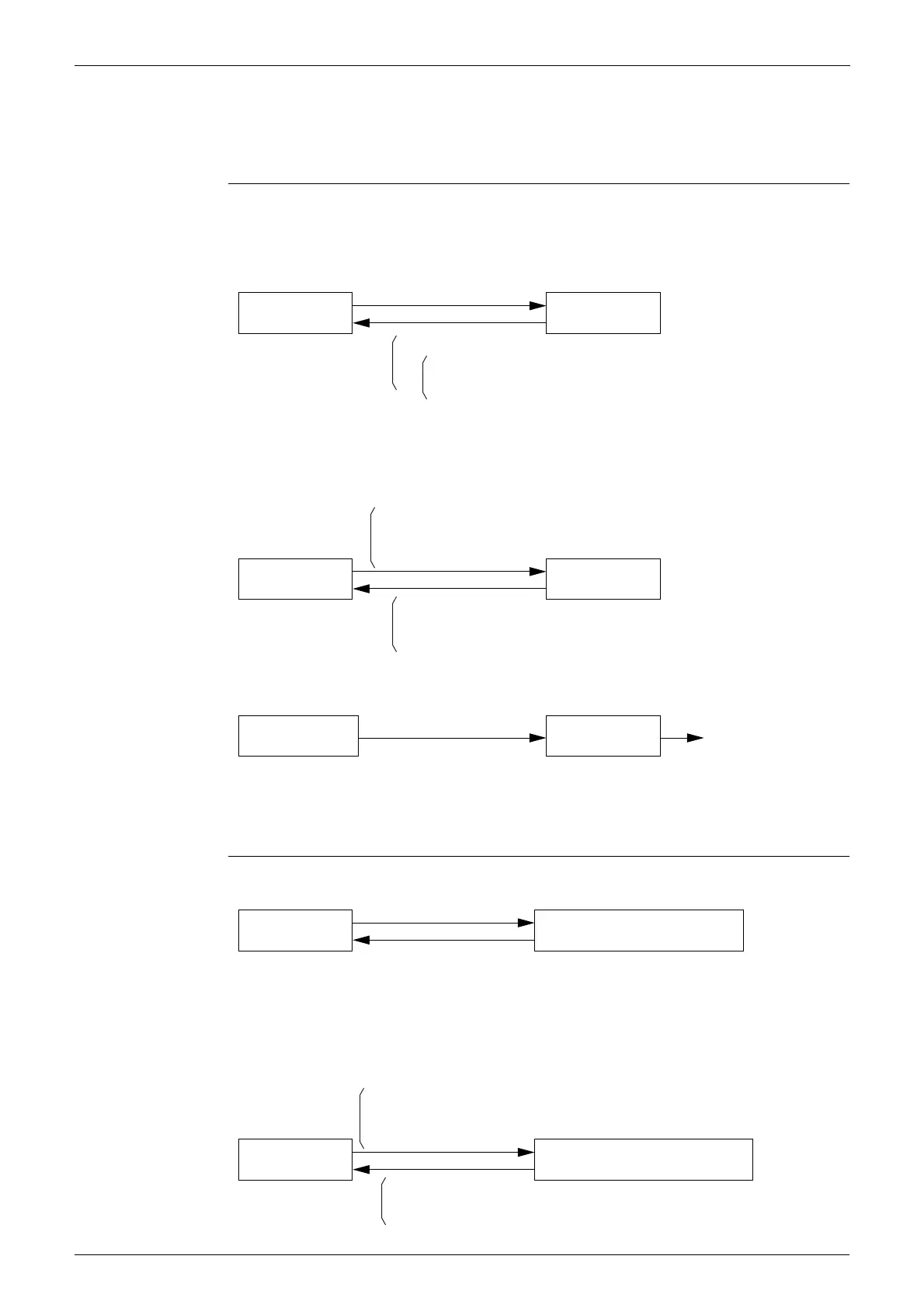

Normal operation

SVTs1 (Y4S), SVTs2 (Y6S) : ON

10 min

DSHs1, DSHs2≥40˚C

DSHs1, DSHs2<15˚C

(V0829)

Normal operation

SVTs1 (Y4S), SVTs2 (Y6S) : ON

2 min

• Tds1, Tds2≥100˚C

• LP<0.05MPa

• (HP+0.10) / (LP+0.10)>8

• Tds1, Tds2<90˚C

• LP<0.07MPa

(V0830)

OR

&

Loading...

Loading...