116

APEX615n Installation Guide

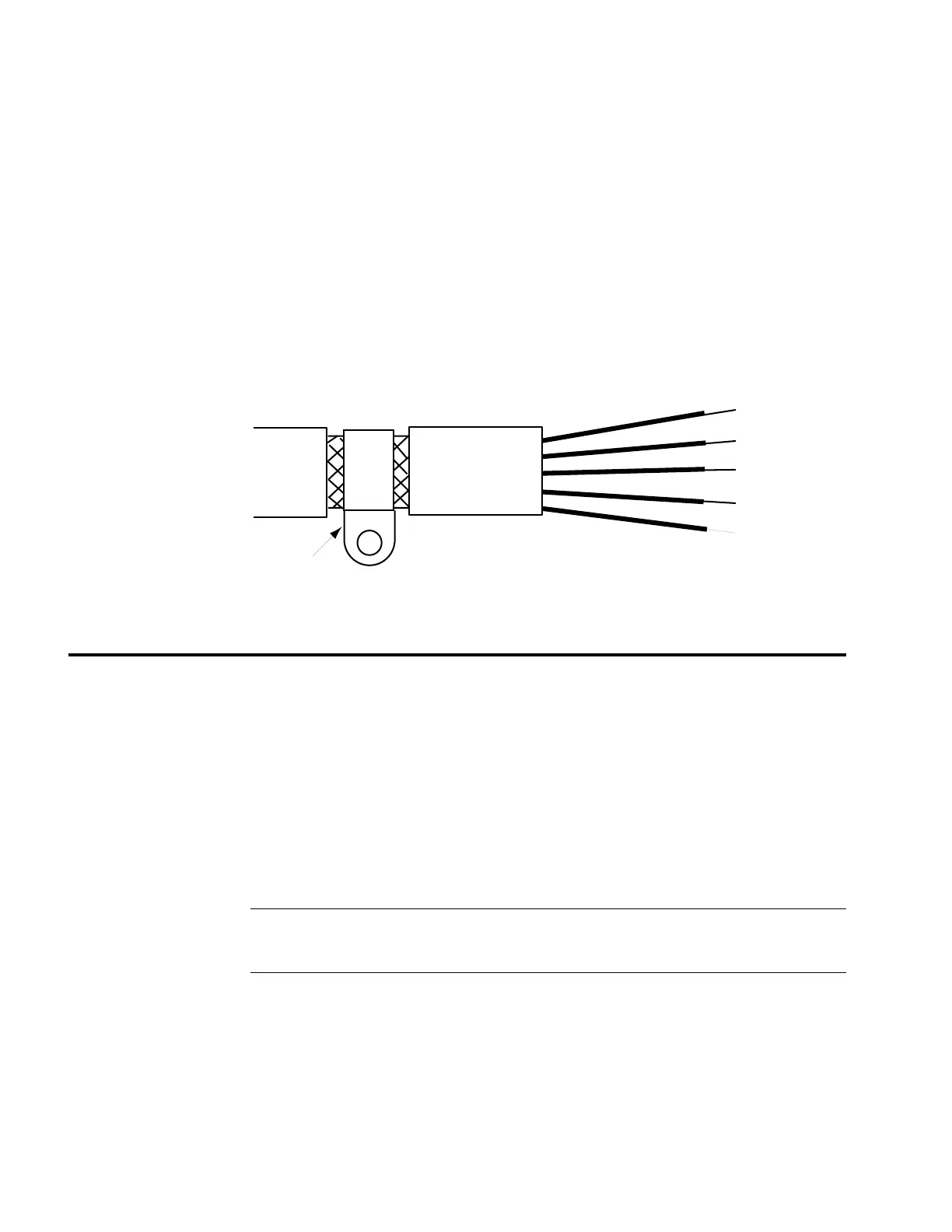

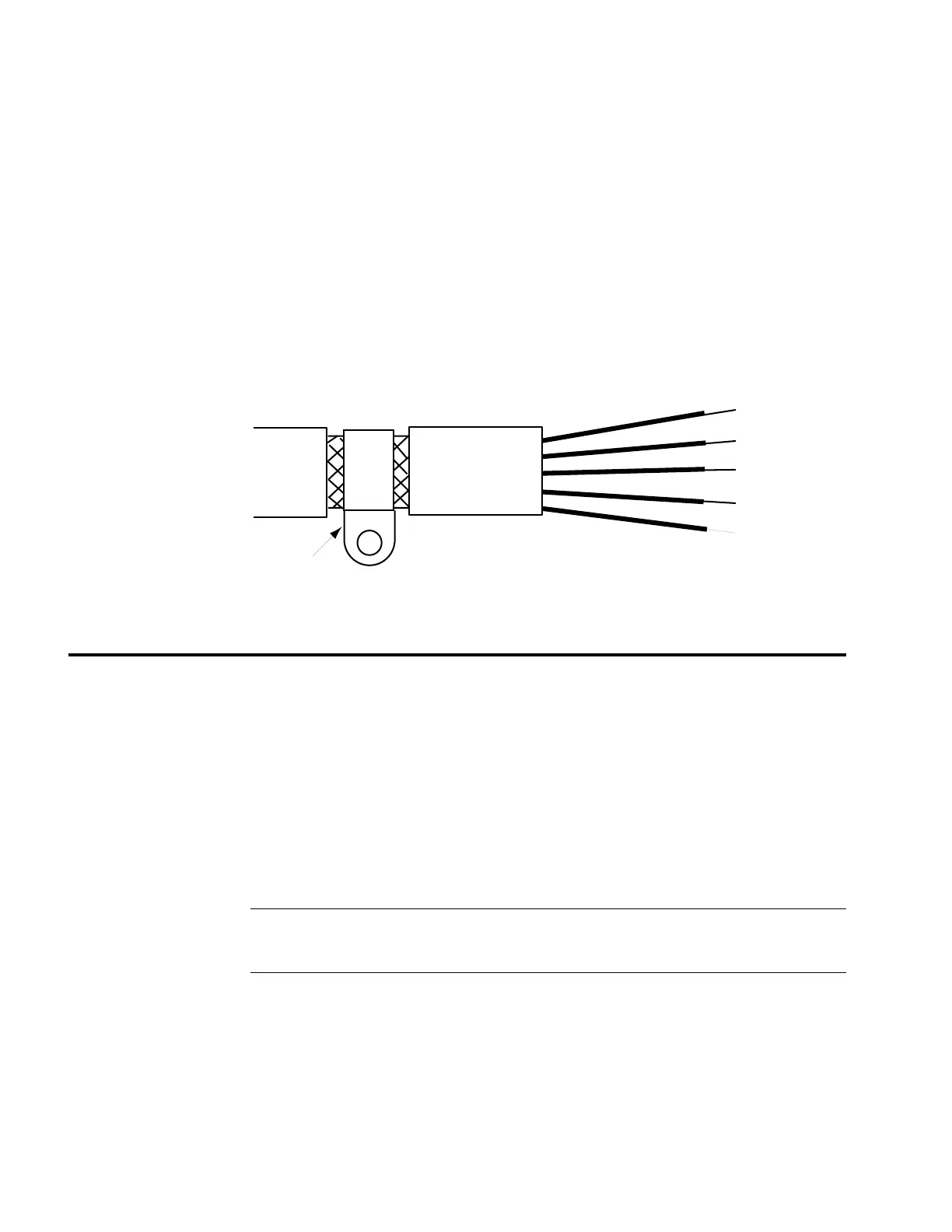

P-Clip Installation Details

The function of the P-Clip is to provide a 360 degree metallic contact and thus a convenient

means of ensuring a proper R.F. ground. When dealing with EMI issues, it is important to

remember that continuity, a DC connection, does not at all speak to the integrity of an AC

(high-frequency) connection. High-Frequency bonding typically involves wide, flat cabling to

establish a suitable system ground. When applied properly, the P-Clip has been shown to give

an adequate high-frequency contact.

When installing a P-Clip, Figure 2, install as close to the cable end as possible, provided a

suitable ground, backplane, earth stud or bus bar is accessible, (this may mean removing the

paint from a cabinet or panel). Remove only the outer (vinyl) jacket of the braided screen cable

(this allows the braid to continue to the cable connector), be careful not to damage the braid.

Snap the P-clip over the exposed braid, and adjust for a tight fit. Secure the clip to the

designated ground with a machine screw and lock washer. The use of brass or other inert

conductive metal P-Clip is recommended. Cover any exposed bare metal with petroleum jelly

to resist corrosion.

P-Clip

Remove outer jacket only

do not cut braid

Figure 2 - P-Clip Installation

APEX615n Servo Controller/Drive

Applicable Products: APEX6151, APEX6152, APEX6154

Please read this in conjunction with the general considerations applicable to all products.

To insure proper grounding of the APEX615n Controller/Drive, remove paint from the rear

panel that is located behind the upper right mounting slot on the drive. The upper right slot is

unpainted. You can use a star washer with the mounting screw in this slot to provide a

grounding path from the chassis ground to the unpainted mounting surface. After mounting

the unit use petroleum jelly on the exposed metal to minimize the risk of future corrosion.

Filtering the AC mains supply

A filter must be installed between the incoming AC supply and the input to the drive.

Suitable filters are:

AC Mains AC Mains

Controller/ Filter AC Control Filter Filter

Drive Manufacturer Filter 1-Phase 3-Phase

120/240VAC 120/240VAC 120/240VAC

APEX6151 Schaffner FN610-3-06 FN2070-16-06 Not Applicable

Schaffner FN2070-3/06 Not Applicable

Corcom 3EB1 * Not Applicable

APEX6152 Schaffner FN610-3-06 FN258-16-07 FN258-16-07

Schaffner FN2070-3/06 Not Applicable

Corcom 3EB1 * 20AYT6C

APEX6154 Schaffner FN610-3-06 FN258-16-07 FN258-16-07

Schaffner FN2070-3/06 FN258-30-07

Corcom 3EB1 * 20AYT6C

* Test Pending

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...