K3.1.141e Manual NitroFlow HP_EN.doc - 45 -

8 Troubleshooting

8.1 Troubleshooting list

In case of trouble always start with calibrating the O

2

sensor (refer to §9.5).

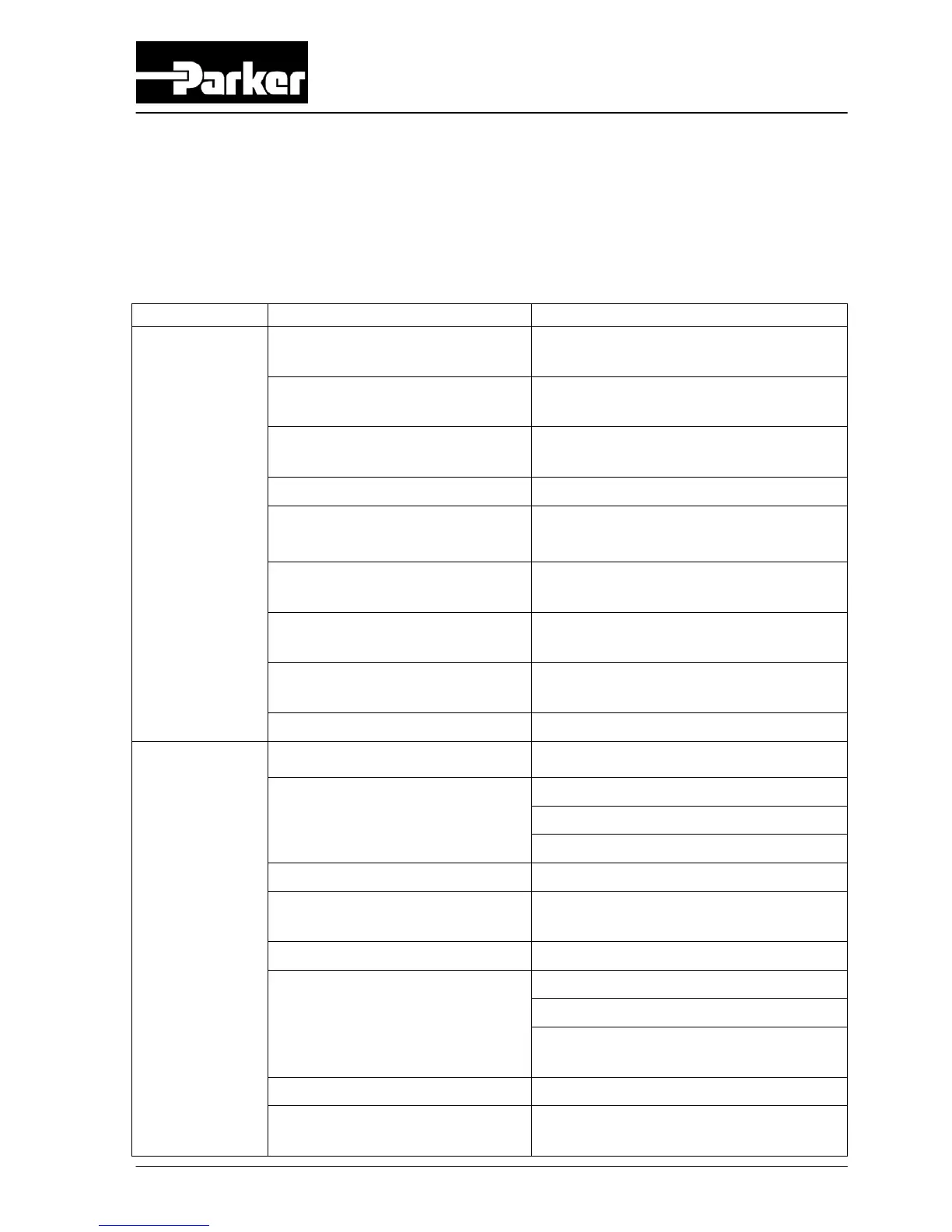

Trouble Possible cause Possible solution

Compressed air supply too

low

Check / increase the air supply

Leak in piping (external or

internal)

Check for leaks in external and

internal piping.

Compressed air temperature

is too high

Lower the temperature, if possible

Air filters are polluted Change or clean the air filters

Automatic drain is

continuously open

Check the automatic drain.

Refer to §9.3 and §9.2.

Flow control valve (FCV1) is

set incorrect

Adjust valve FCV1 to correct setting.

Sample flow to O

2

sensor is

too low

Check / readjust the sample flow to

the O

2

sensor. Refer to §9.5.

Nitrogen outlet line is

restricted

Check / open the outlet line

Delivery (flow)

of nitrogen too

low

Faulty module set(s) Check / replace module set(s)

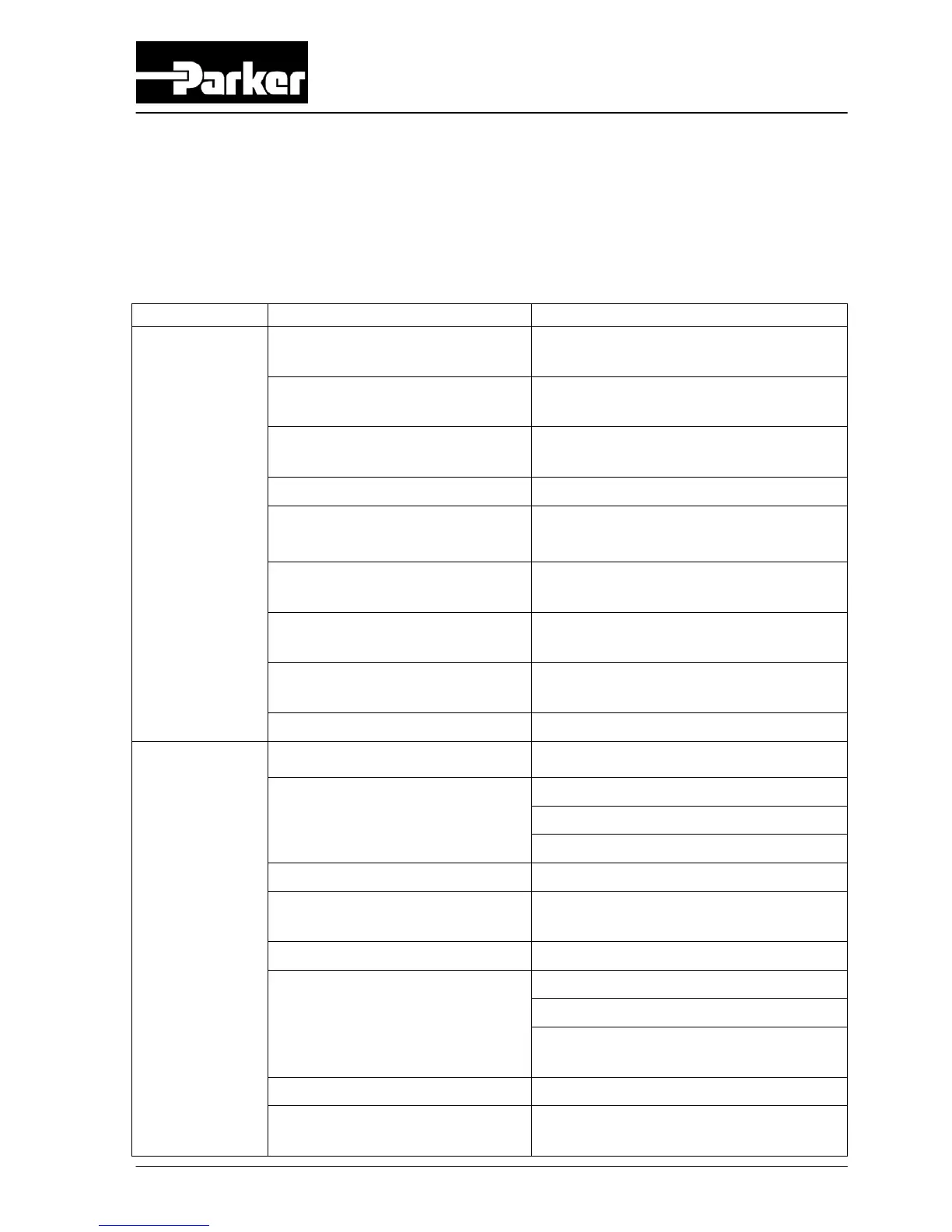

NitroFlow

®

HP is switched off Switch on the NitroFlow

®

HP

Check fuses

Check mains switch

No power

Check voltage power supply

No compressed air available Check compressed air supply

Loose tubing (internal or

external)

Check / restore tubing and piping

Nitrogen outlet line is blocked. Check / open the outlet line

Check / reduce inlet temperature

Replace temperature sensor

NitroFlow

®

HP is in alarm

Check / reduce inlet pressure

(absolute maximum is 15 bar(g))

Solenoid valve failed

Check / replace solenoid valve

No nitrogen

delivery

Flow control valve (FCV1) is

closed completely

Check / readjust valve FCV1

Loading...

Loading...