TR-6-12

28 May 2009TRIMMING PROCESS

Trimming

Booklet maker sends a start signal. The transport motor (TR-M1) starts and trans-

ports the booklet into the machine. The infeed sensor (TR-Q13) is activated by the

booklet. The booklet passes and deactivates the infeed sensor (TR-Q13). When

the booklet hits the stop gate, the transport motor (TR-M1) stops. The timing is

controlled by transport motor sensor (TR-Q4) and set by the paper size.

Trim knife motor (TR-M2) starts moving the knife down. After a while when the

knife is about to cut the sheets, transport motor (TR-M1) is triggered by knife posi-

tion sensor (TR-Q5) to reverse and helps knife motor (TR-M2) during the cutting

stroke. About the time when the knife has cut through the sheets, the stop gate

motor (TR-M3) moves the stop gate down and the transport motor (TR-M1) re-

verses again to transport the set out of the machine. The knife motor completes its

cycle and stops at the trim knife home position sensor (TR-Q5).

The stacker motor (ST-M1 - not shown in picture) starts when the outfeed sensor

(TR-Q6) activates and runs for a short while to separate the booklets on the stack-

er belt. When outfeed sensor (TR-Q6) activates, stop gate motor (TR-M3) moves

the stop gate to up position and is stopped when the stop gate home position sen-

sor (TR-Q7) activates.

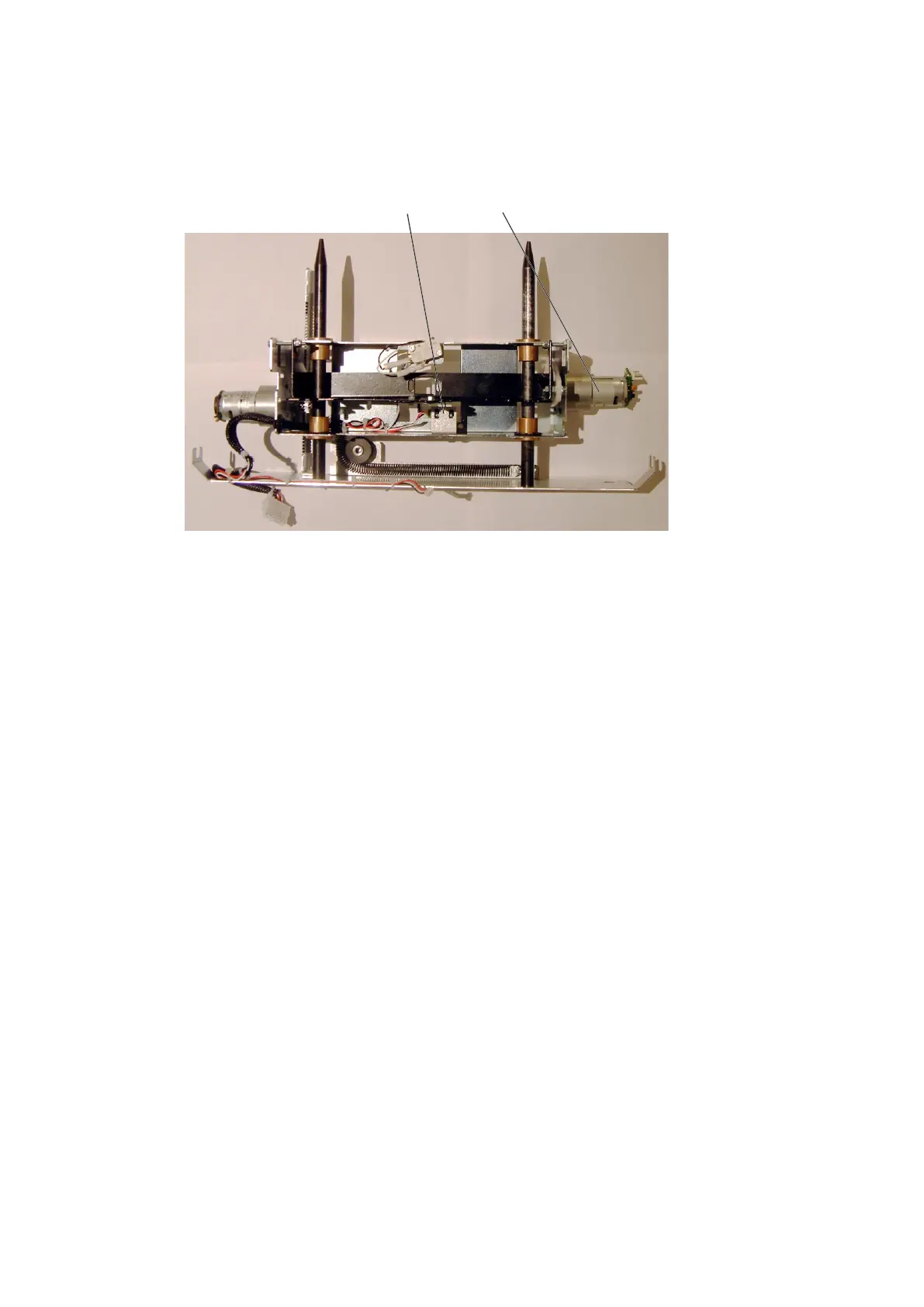

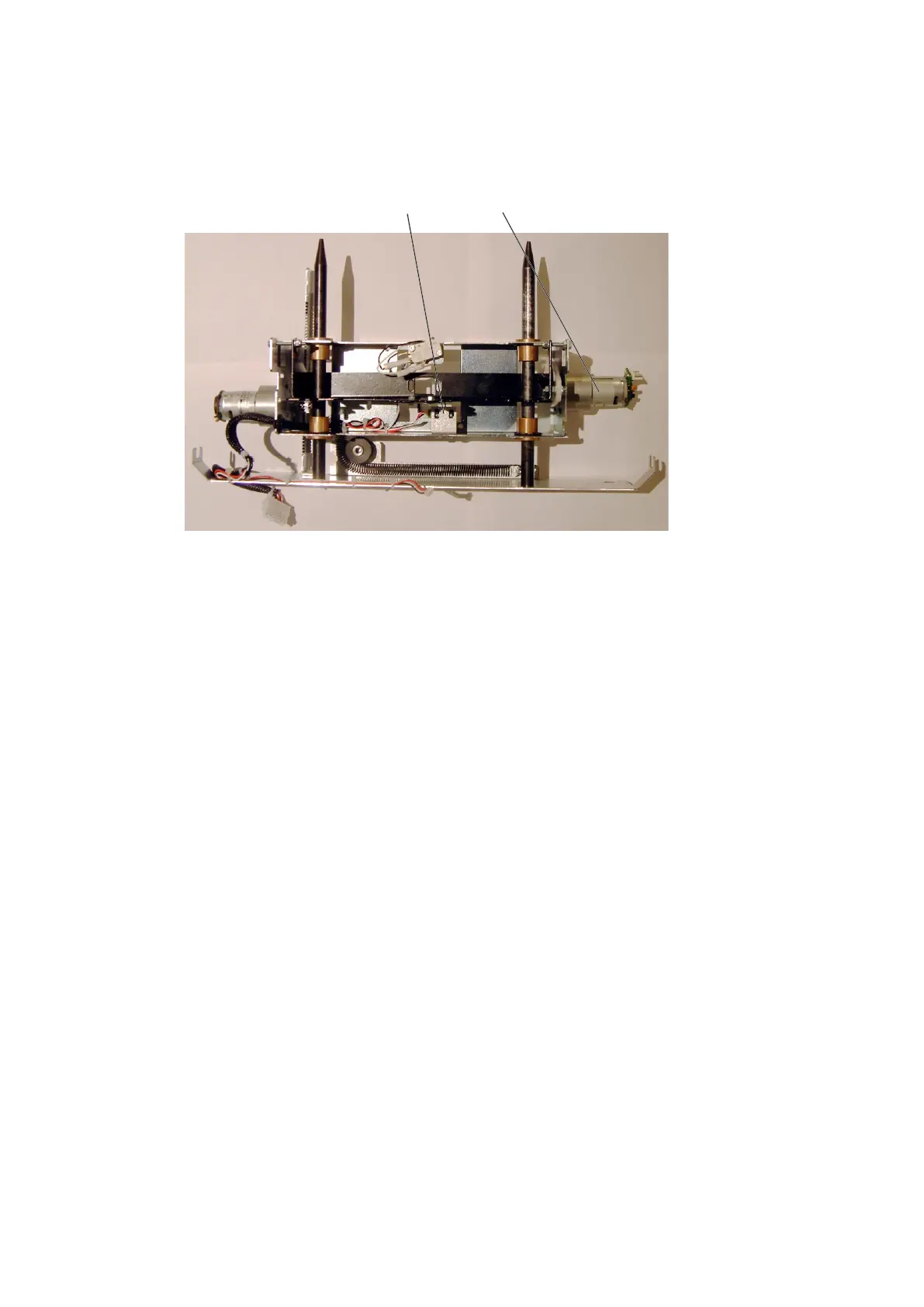

TR-M3TR-Q7

Loading...

Loading...