© 2017 PoolPak LLC. All rights reserved. MPK Series - Installation, Operation and Maintenance | 31

PoolPak

®

MPK Series IOM

For ground-level installation, a one-piece concrete slab with footers that extend below the frost line is highly

recommended. Additionally, the slab should not be tied to the main building foundations to prevent noise

transmission. The unit must be supported with adequate space to allow for a condensate line trap.

For roof-top installation, choose a location with adequate structural strength to support the entire weight of the

unit and service personnel. For non-curb mounted units, provide spring vibration isolation to minimize vibration

transmission to the roof structure. The unit must be situated with adequate height for a condensate line trap. The

PoolPak unit may be mounted on equipment rails with spring vibration isolation. For any alternative mountings not

discussed here, contact the factory for additional guidance. Care must be taken not to damage the roof. If the roof

is bonded, consult the building contractor for allowable installation procedures.

Inspection

Immediately upon receiving the unit, inspect it for damage which may have occurred during transit. If damage is

evident, note it on the carrier’s freight bill. A written request for inspection by the carrier’s agent should be made at

once.

Unit Hookup

Avoid tearing or damaging unit insulation while working on or around the unit. Do not stack access panels. Stand

them upright with the insulation away from traffic.

GAS FURNACE AUXILIARY HEAT OPTION

When using a gas furnace, power venting is provided for all unit sizes. External vent piping and/or cap is required.

Please refer to the furnace manufacturer’s manual for piping and venting instructions. Install, leak-test, and properly

regulate piping for the gas-fired heater. Pressures should be regulated to the entering pressures as shown on the

furnace manufacturer’s data plate or manual.

POWER SUPPLY

The contractor is required to supply (unless supplied as an option by PoolPak) and install separate fused

disconnect(s) within easy accessibility of the PoolPak unit. Use the minimum circuit capacity listed on the unit’s

data plate to determine the minimum wire size for incoming electrical power. The ground connection for the unit

is located in the unit control panel. The power supply to the unit must be adequate for the compressor starting

amperage (LRA). All field wiring must be done according to the wiring diagram provided with the unit and in

conformance to the National Electrical Code (NEC) and any other applicable local electrical code. Conduits

connected to outdoor units must be sealed in accordance with NEC 300.7 (A)

If a remote air-cooled condenser is required, a separate power feed must be provided for the air-cooled condenser.

When the auxiliary electric heater option is provided, another power connection point is provided in the electric

heat compartment. This power connection feeds the auxiliary electric heating coil. With this option, the contractor is

required to supply and install a second fused disconnect.

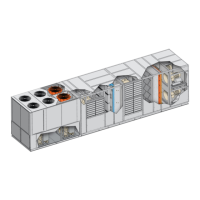

PoolPak MPK units are available in single and dual point power supply options. The 208V option is dual point

power only. See illustrations.

Loading...

Loading...