www.poolpak.com | 800-959-772540 | MPK Series - Installation, Operation and Maintenance

Pool Water Piping and Installation

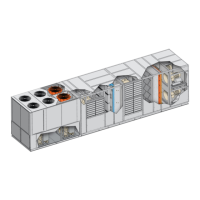

PoolPak Pool Water Circulation Loop

The PoolPak unit pool water condenser (full or partial) must be connected to a secondary circulation loop with its

own circulation pump (field-supplied) to obtain the required design water flows. A typical piping configuration is

shown in Figure 4-5.

The secondary pool water loop supply must come from the main pool water distribution line downstream of the

main pool water pump and the pool filter and before the take off to the auxiliary pool water heater. The discharge

from this secondary loop goes back into the primary distribution line downstream of the secondary loop supply and

upstream of the auxiliary pool water heater. This location is required so that the PoolPak® unit will sense the actual

pool water temperature.

The secondary circulation loop pump should be located near the main pool water distribution line on the supply line

of the secondary loop feeding the PoolPak® unit. The pump should be self-priming and vented. The pump should be

located at the lowest point possible in this secondary circulation loop. For example, if the PoolPak® unit is located

on a mezzanine and the main pump filter are located in the basement below the mezzanine; the second pump

should be located in the basement with the filter, not on the mezzanine with the PoolPak® unit. Particular attention

must be given to venting when the PoolPak® unit is installed above the level of the main pool water system. When

designing a system that has over 20 to 30 feet of vertical rise, the system should be considered to be open (size

pump accordingly, assuming no gravitational assistance).

Auxiliary Water Heater (Field Supplied)

The auxiliary pool water heater must be installed downstream of the PoolPak® unit’s secondary loop discharge. It

is normally installed in its own secondary loop as shown in the figure. The auxiliary pool water heater is controlled

by the PoolPak® System. It is only turned on either when the heat available from the PoolPak® is insufficient for

pool water heating and pool water temperature drops to 1.5°F below set point or when the pool water flow to the

PoolPak® unit is below the minimum required water flow.

Main Pool Water Pump and PoolPak Pool Water Loop Pump Interlocks

The main pool water distribution pump and the PoolPak® pool water loop pump must each have its own start/stop

switch. Wire the main pool water pump’s auxiliary contacts in accordance with the manufacturer’s specifications,

and run the wires to the PoolPak® unit auxiliary pool water loop pump starter. Wire the auxiliary pump so that it

operates only when the main pool water pump operates. This interlocking is necessary to prevent overheating and

possible damage to the pool water piping and PoolPak® pool water loop pump.

Pool Water Isolation Valves

Hand stop valves and pressure gauge stopcocks are factory-installed in the pool water supply line and return

line inside the PoolPak® unit for servicing. A third hand valve (field-supplied) should be installed upstream of the

auxiliary pool water pump so that the pump can be isolated for service. A fourth hand valve (field-supplied),

installed in the main pool ater line between the secondary loop supply and return, is normally required to balance

the flow in the PoolPak® unit secondary loop.

Pool Water Pressure Transducer

Pool water pressure transducers are factory-installed in the MPK unit. The pressure transducers can be calibrated

through the CPCS controller if necessary. The pressure transducers measure the difference in water pressure across

the pool water condenser and display this head pressure in units of water column (feet of head). This reading is

used to determine whether proper flow has been received by the MPK unit. The MPK unit can be operated with

inadequate water flow; however, the MPK System will not go into a water-heating mode until the head pressure

reaches the required value.

Loading...

Loading...