© 2017 PoolPak LLC. All rights reserved. MPK Series - Installation, Operation and Maintenance | 79

PoolPak

®

MPK Series IOM

adjusted. This ability is especially important when calibrating sensors or in the event of a failed sensor in order to

continue normal operation.

DIGITAL AND ANALOG OUTPUT CONFIGURATION

Input/Output Configuration (I/O Config) is a selectable option in the Service menu of the Controller. With this

function, the qualified HVAC service technician has access to Digitial Outputs and Analog Outputs.

DIGITAL OUTPUT

Each digital output of the CPCS controller may be controlled individually by setting the corresponding parameter to

one of three possible values: AUTO, ON, or OFF. A setting of AUTO gives control of the digital output relay to the

software in the CPCS. ON will force the output relay to energize regardless of the status requested by the software.

OFF will force the output relay to de-energize regardless of the status requested by the software.

The digital outputs found in this menu are solenoid valves, fan start signals, compressor run signals, auxiliary heat

run signals, smart pump enable, and more.

ANALOG OUTPUT

Each analog output of the CPCS controller may be controlled individually by setting the corresponding parameter.

This is helpful determining functionality of auxiliary control valves or dampers.

Startup & Warranty

Pre-startup

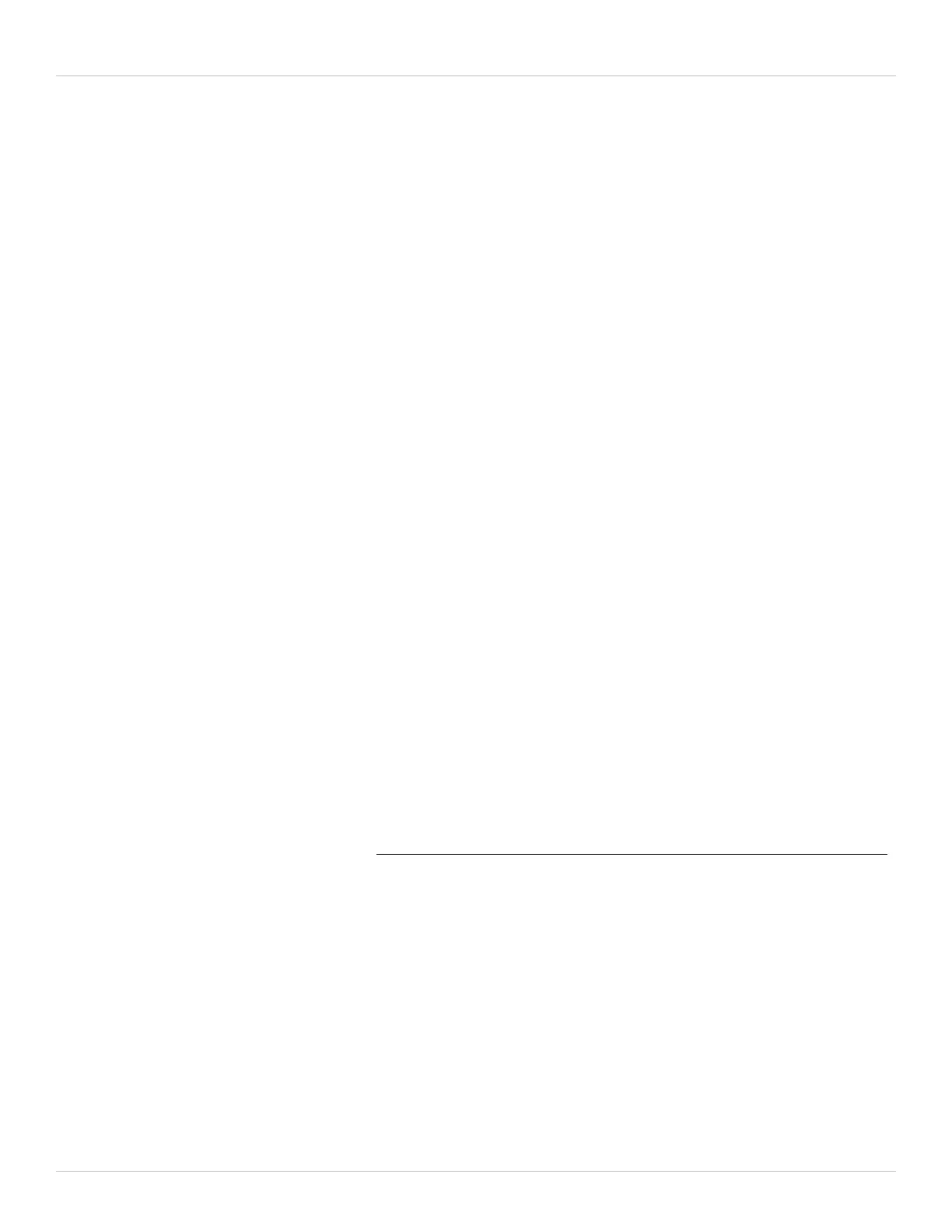

After receiving the PoolPak® unit, there are several tasks to complete before scheduling the factory startup. PoolPak

Service maintains and provides a checklist of these activities that they require in order to schedule startup.

This checklist provides additional confirmation of the proper installation of the unit and any field installed

components. These items include but are not limited to field wiring for remote ACC/WCC, field wiring for field

installed sensors, refrigerant piping for remote ACC/WCC, and water piping for pool water and remote WCC

applications.

This checklist determines that the space conditions and unit condition will be suitable for startup. If the checklist is

completed satisfactorily, startup and owner training can be accomplished in a single day.

This pre-startup checklist will be given at the time of order acknowledgement. It can also be found in the PoolPak

website, www.poolpak.com, under the Start-up and Warranty Information section of the Parts & Service Downloads

page.

Startup

PoolPak Service requires a minimum of 2 weeks notice to allow adequate time to schedule startup. This 2 weeks

notice includes a completed pre-startup checklist as described above. If Startup is required within the first month

of shipment, special arrangements must be made with PoolPak Accounting Department at the time of Order

Acknowledgement.

In instances where the equipment start-up will be delayed, a Delayed Startup Warranty Extension may be

purchased in one-month increments for up to an additional 12 months. This delayed startup can be purchased any

time before the actual startup. Contact PoolPak Service at service@poolpak.com to apply.

Loading...

Loading...