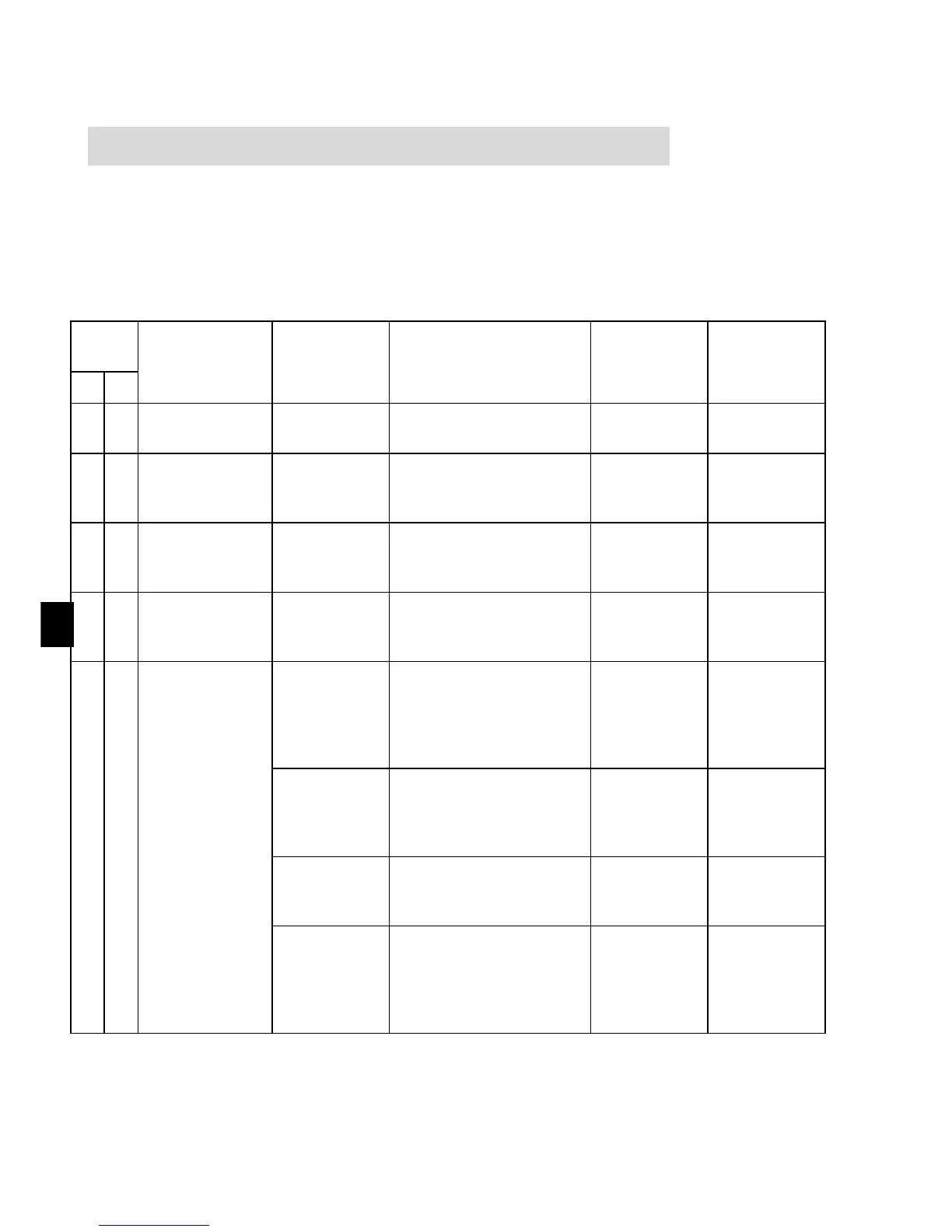

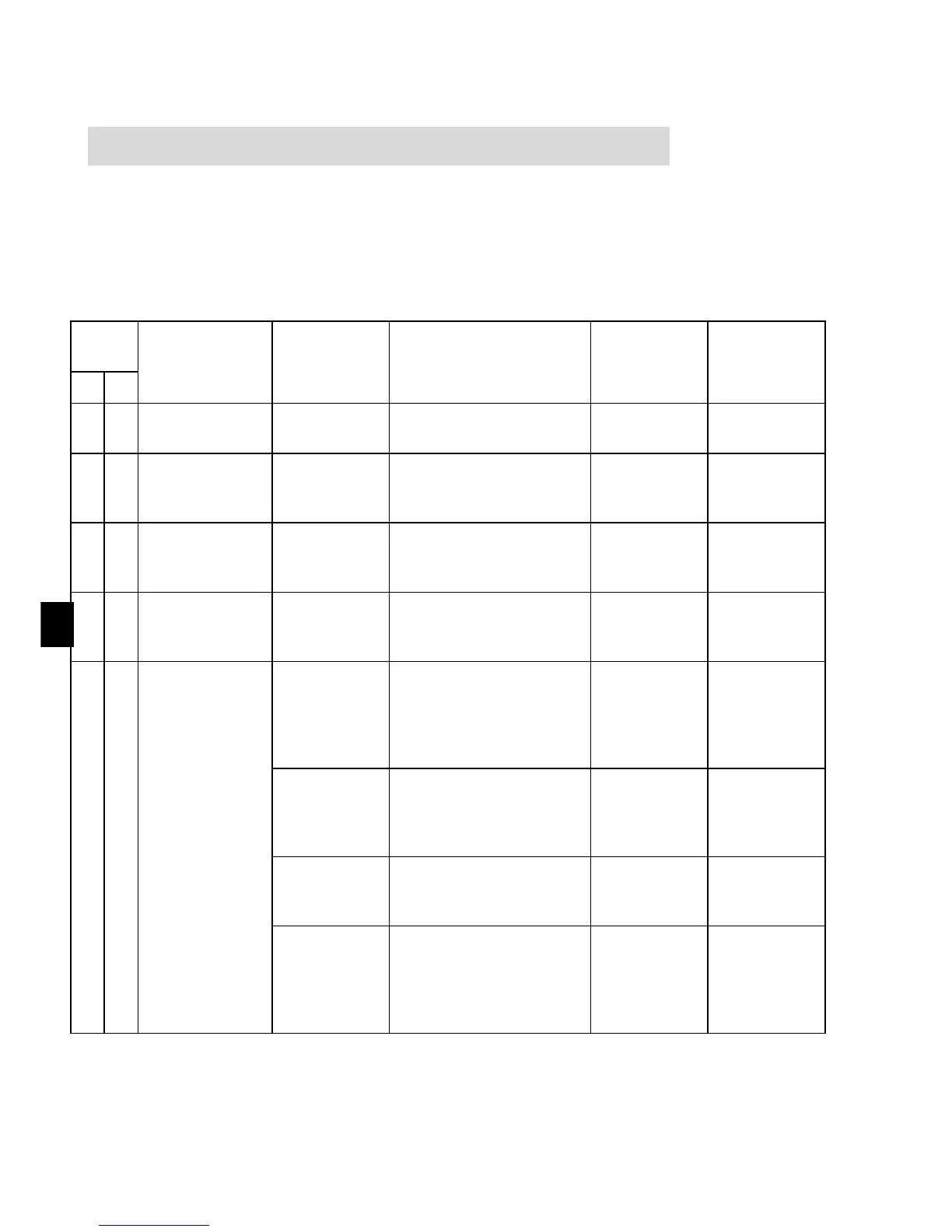

Section VIII Inspection & Maintenance

8-1. Inspection and Maintenance

Under normal working conditions, in addition to daily inspection, the frequency converter

should be subject to regular inspection (for example inspection for overhaul or as specified but at an

interval of six months at most). Please refe r to the following table in order to prevent faults.

If there is any abnormal

display

If abnormal noise or

vibration is produced.

No abnormal

sound or

vibration

Temperature,humidity,

dust content, harmful gas,

etc.

Check visually,

by smelling

and feeling

If input, output voltage is

abnormal

Measure at R,

S, T and U, V,

W terminals

As per

standard

specifications

Main circuit Body

Input/ output

terminal Main

circuit

If the fastenings come

loose, if any signs show

overheat,discharging,or

too high dust content, or

the air piping is blocked

Check visually,

tighten the

fastenings, and

clean the

related parts

Temperature,humidity,d

ust content, harmful gas,

etc.

Check

visually, by

smelling and

feeling

If input, output voltage

is abnormal

Measure at R,

S, T and U, V,

W terminals

As per

standard

specifications

If the fastenings come

loose, if any signs show

overheat,discharging, or

too high dust content, or

the air piping is blocked

Check visually,

tighten the

fastenings, and

clean the

related parts

“√” means need daily check or regularly check

For inspection, do not disassemble or shake the parts without reason, and still less pull off the

plug-in-parts at random. Otherwise, the unit will not operate normally, or can not enter the mode of

fault display, or causes faults of components or even parts of the main switch components IGBT

Loading...

Loading...