5.3.4 Installation (electrical)

The cable must be routed in a site-

provided cable duct to ensure strain

relief

1. Undo the four housing screws

2. Slightly lift the controller housing

top section forwards and fold it to

the left

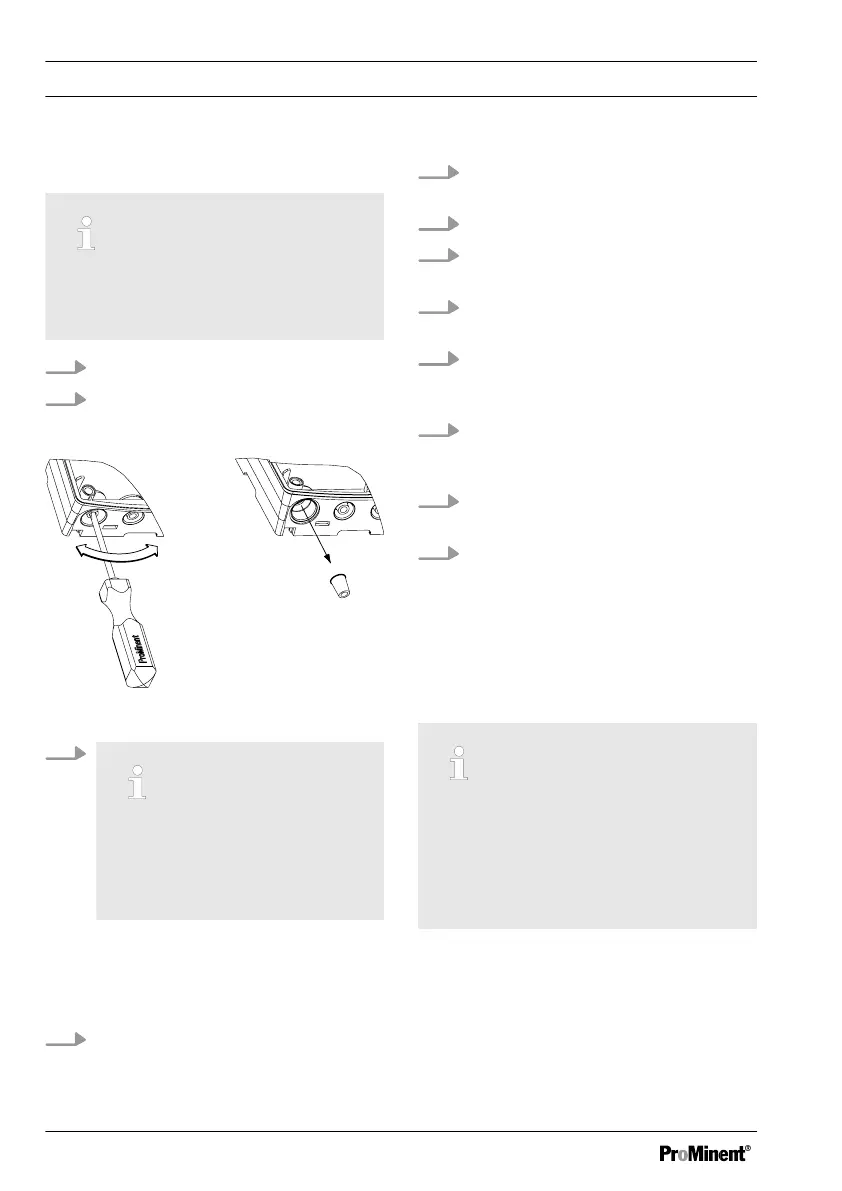

Fig. 14: Punch out threaded holes

3.

Large threaded connection (M

20 x 1.5)

Small threaded connection (M

16 x 1.5)

Punch out as many threaded con‐

nections on the bottom side of the

controller housing bottom section

as required

4. Guide the cable into the respective

reducing inserts.

5.

Insert the reducing inserts into the

threaded connectors

6. Guide the cable into the controller.

7. Connect the cable as indicated in

the terminal diagram

8. Screw the required threaded con‐

nections in and tighten

9. Tighten the clamping nuts of the

threaded connections so that they

are properly sealed

10. Click the controller housing top sec‐

tion on to the controller housing

bottom section

11. Manually tighten the housing

screws

12. Once again check the seating of the

seal. Only if the mounting is correct,

is protection class IP 67 (wall/pipe

mounting) or IP 54 (control panel

mounting) achieved

5.4 Switching of inductive loads

If you connect an inductive load, i.e. a

consumer which uses a coil (e.g. an

alpha motorised pump), then you

must protect your controller with a

protective circuit. If in doubt, consult

an electrical technician for advice.

The RC member protective circuit is a

simple, but nevertheless very effective,

circuit. This circuit is also referred to as a

snubber or Boucherot member. It is pri‐

marily used to protect switching contacts.

Assembly and installation

38

Loading...

Loading...