APPENDIX C

116 RCM - Sprayer and AIM Command FLEX™ II Calibration and Operation Manual

NOZZLE CONTROL VALVE MAINTENANCE PROCEDURE

AIM Command FLEX™ II nozzle control valves are designed to provide maintenance free operation with proper

equipment maintenance as recommended by the equipment or chemical manufacturer. However, the seals may

become worn or swollen due to chemical compounds, chemical formulations, or high operating pressures. This

may cause accelerated wear to the sealing surfaces. The following nozzle control valve maintenance procedures

should be performed on the nozzle control system or on individual NCVs if leaks are observed at a specific spray

tip.

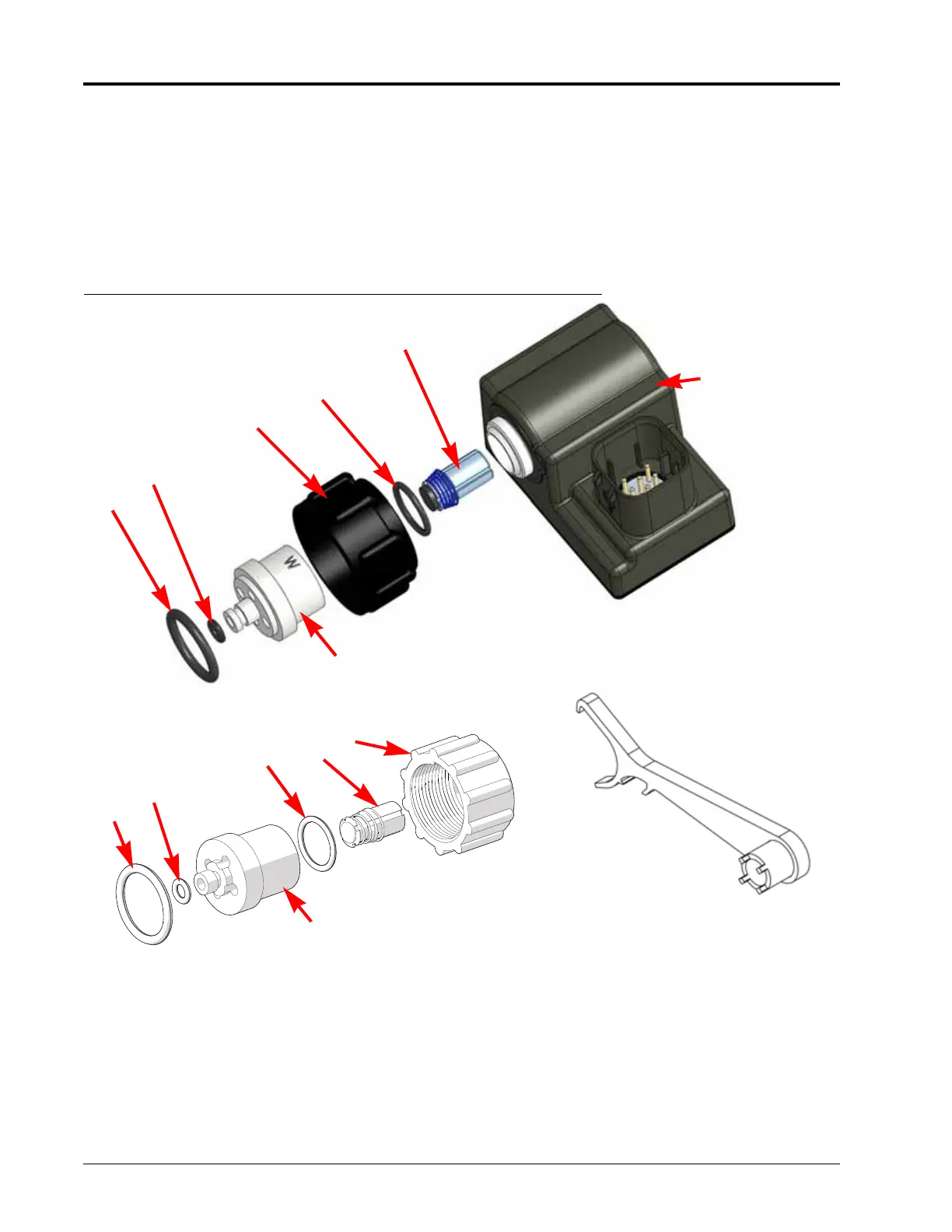

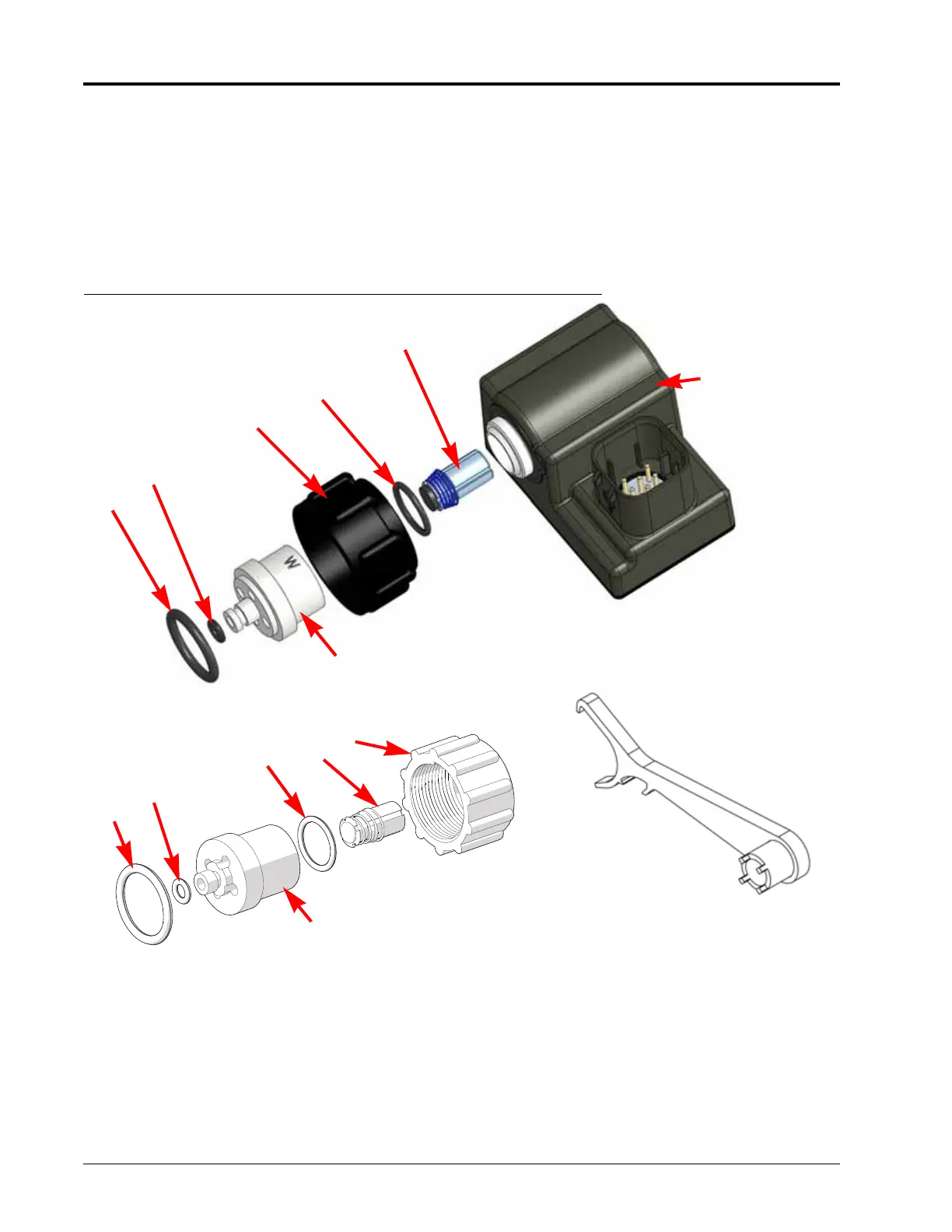

FIGURE 2. Nozzle Control Valve Maintenance Detail

1. Loosen the fly nut (item 1) and remove the AIM Command FLEX™ II nozzle control valve from the nozzle body.

2. Inspect the large o-ring (item 6) on the face of the valve body (item 4). Replace if necessary.

3. Inspect the small o-ring (item 5) on the tip of the valve body. Replace if necessary.

4. Using a valve body removal tool (P/N 321-0000-490), loosen and remove the valve body (item 4) from the AIM

Command FLEX™ II nozzle control valve.

1

2

3

4

5

6

Nozzle

Control Valve

1

2

3

4

5

6

Valve Body Removal Tool

(P/N 321-0000-490)

Loading...

Loading...