APPENDIX

C

: System Maintenance 113

APPENDIX C

MAINTENANCE SCHEDULE

AND REPLACEMENT PARTS

SYSTEM MAINTENANCE

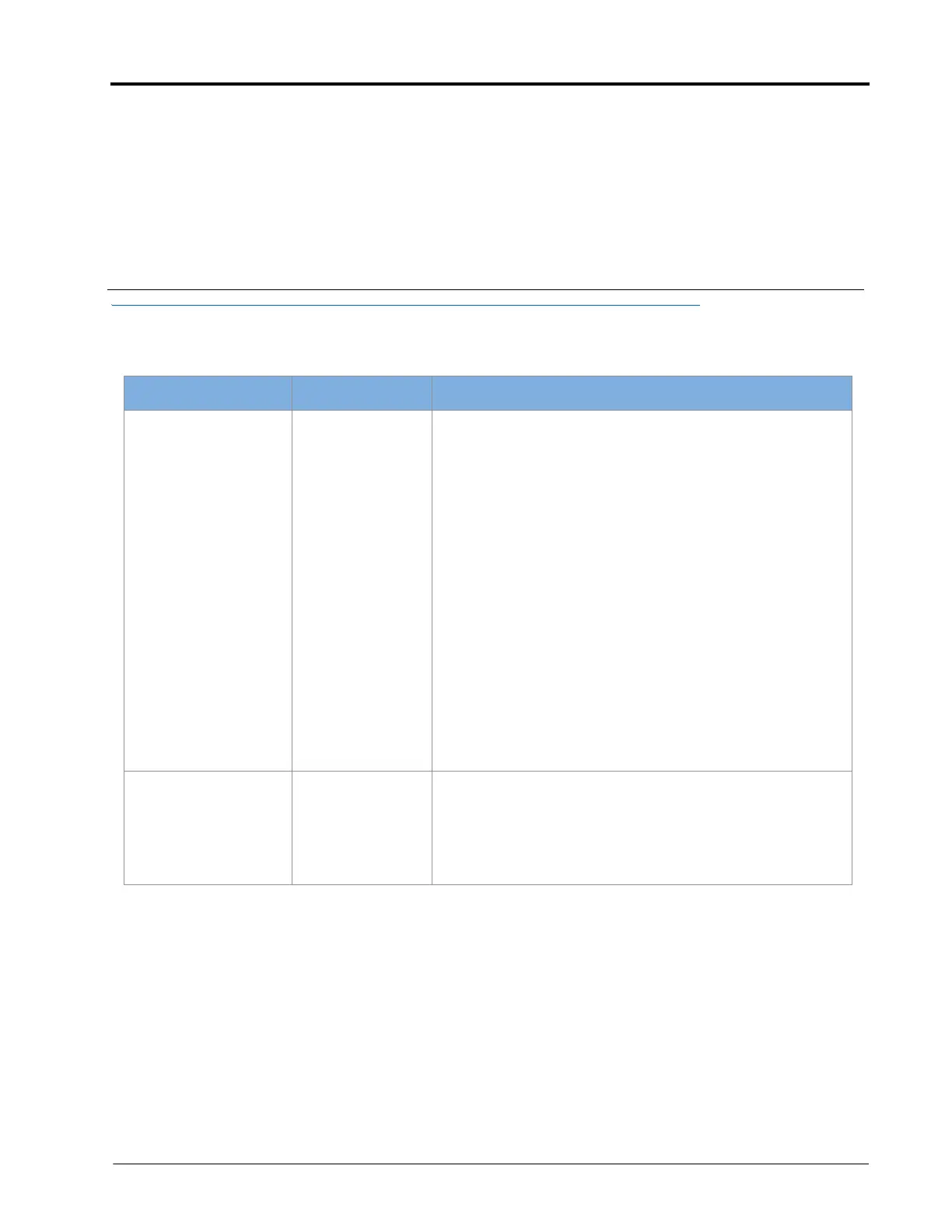

TABLE 1. Maintenance Schedule

Inspection Frequency Procedure

System Rinse Daily after use

1. Ensure the main product tank is cleaned and filled with at

least 100 gallons of fresh water or that the pump is

drawing fresh water from the vehicle rinse tank.

2. Park the sprayer in a safe location to unfold the booms

and spray.

3. Ensure the RCM - Sprayer product control mode is set to

Auto.

4. Enter a target pressure of 40-60 psi [275.8 - 413.7 kPa]

(for applicable NCV control modes) and an application

rate of 10-20 GPA [93.5 - 187.1 L/ha].

5. Set the test speed to 6 mph [9.7 km/h].

6. Enable the sprayer product pump.

7. Turn on all section switches and the master spray switch.

8. Continue to spray water out of the booms until all

chemical is flushed from the system or at least 30

seconds.

9. Turn off the Master Spray Switch.

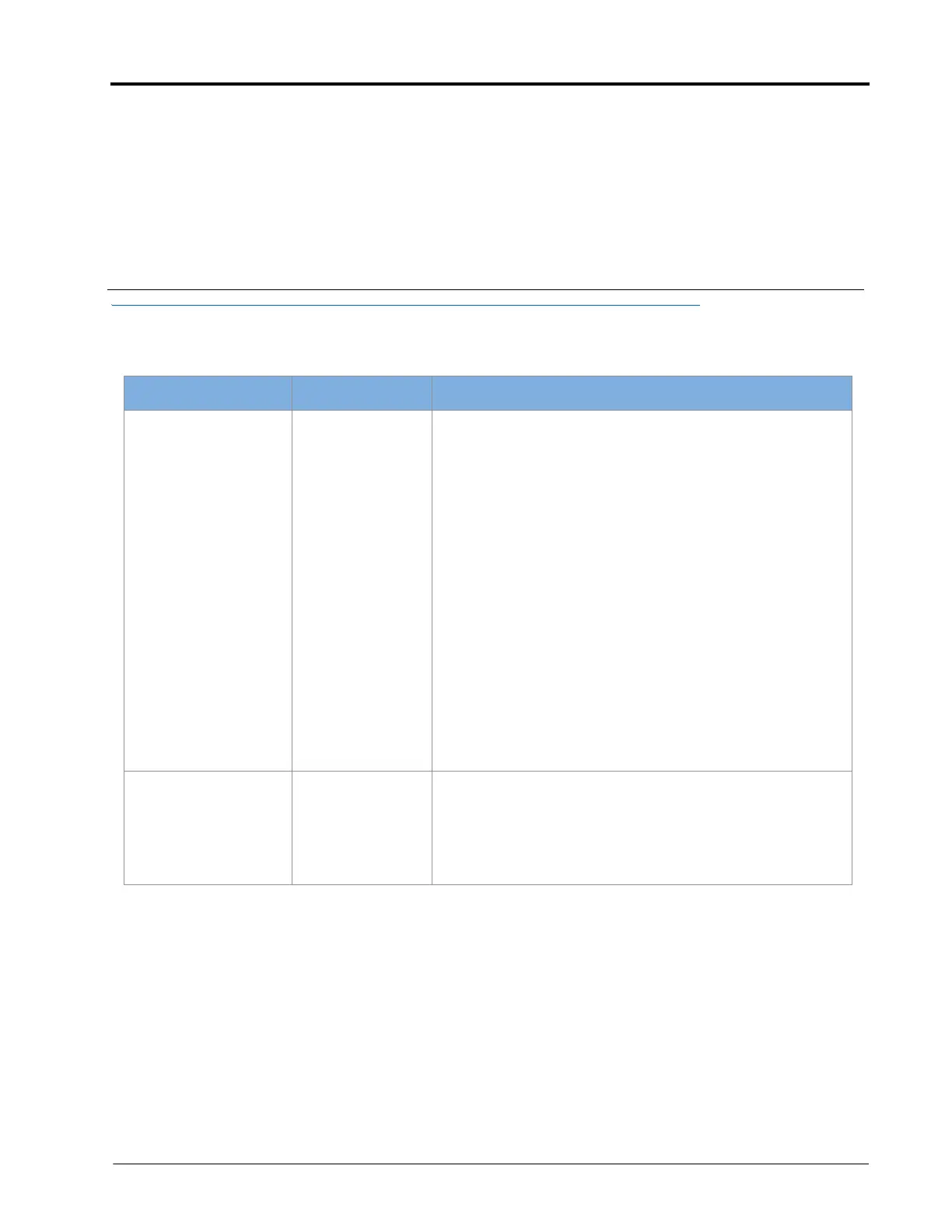

System Rinse (for

sprayers equipped

with Air Blow Out

systems)

Daily after use

1. Perform a system rinse.

2. Set the AIM Command FLEX™ II system to Manual mode.

3. Set the pump PWM to zero and NCV PWM to 50-75%.

4. Follow the vehicle manufacturer’s normal procedure for

the Air Blow-Out function.

Loading...

Loading...