APPENDIX

D

: Power and RCM - Sprayer ECU Harness Maintenance 121

APPENDIX D

CABLE AND CONNECTOR

MAINTENANCE

POWER AND RCM - SPRAYER ECU HARNESS MAINTENANCE

1. Disconnect the RCM - Sprayer ECU harness connector and inspect for signs of moisture or corrosion.

2. If moisture of corrosion is detected, use DeoxIT D5, brushes, and compressed air to clean and dry the

connector.

3. When clean, apply a coating of Corrosion X HD to the connector mating surfaces and contacts.

4. Reattach the connectors.

BOOM HARNESS CONNECTOR MAINTENANCE

Prior to connecting the AIM Command FLEX™ II boom cable to the AIM Command FLEX™ II Nozzle Control Valves

(NCV), perform the following steps to all 8-pin NCV connectors and 19-pin circular connectors between the boom

cables and RCM - Sprayer ECU cable connections to ensure high quality connections:

1. Verify the NCV connectors and the accompanying boom cable connectors are free of moisture, contamination,

or oxidation. Oxidation will appear as a dry, white coating on the contacts. If any connectors show signs of

moisture, contamination, or oxidation, perform Step 2 - Step 6. If this is a new installation, skip to Step 7. All

components listed below can be ordered in the AIM Command FLEX™ II NCV Connection Maintenance Kit (P/

N 117-0171-692).

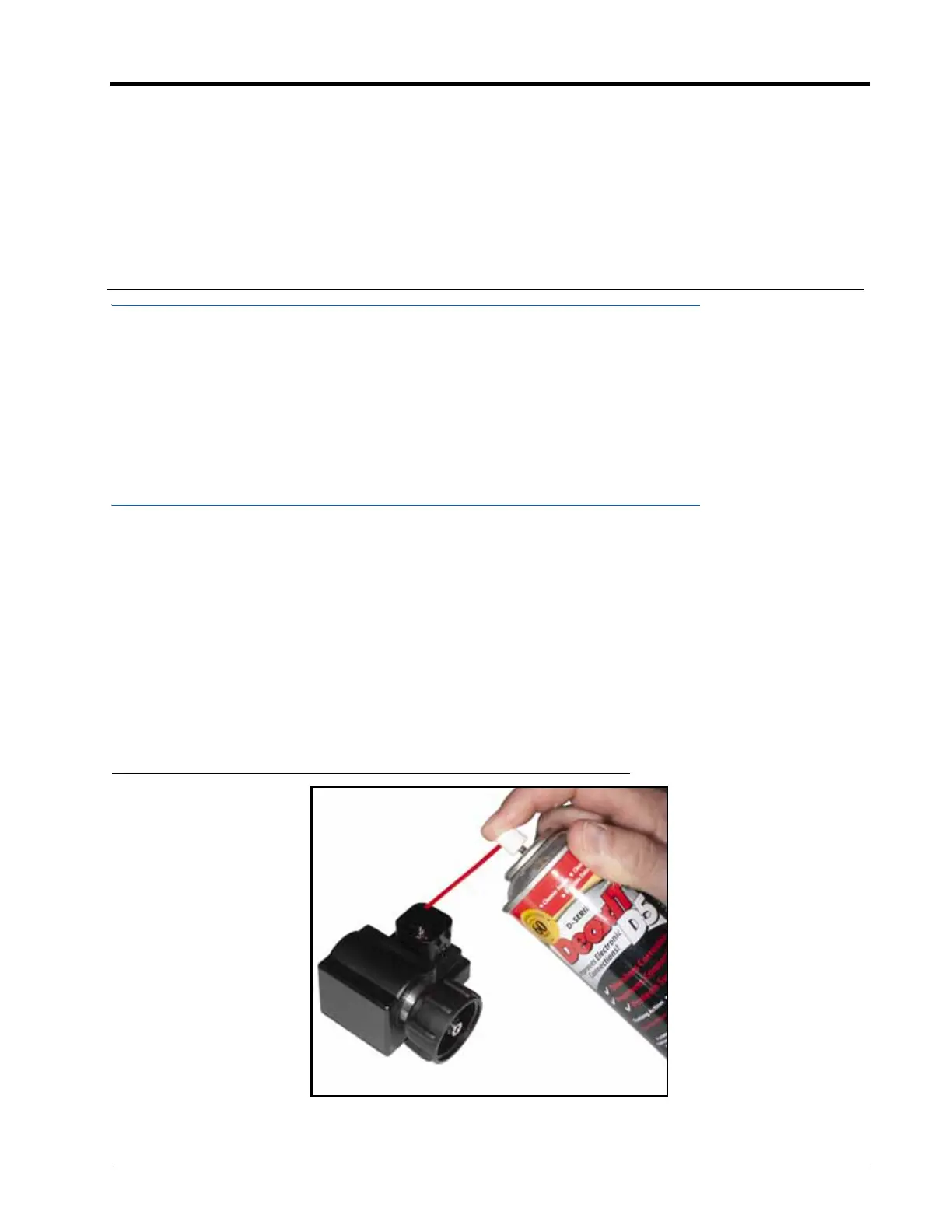

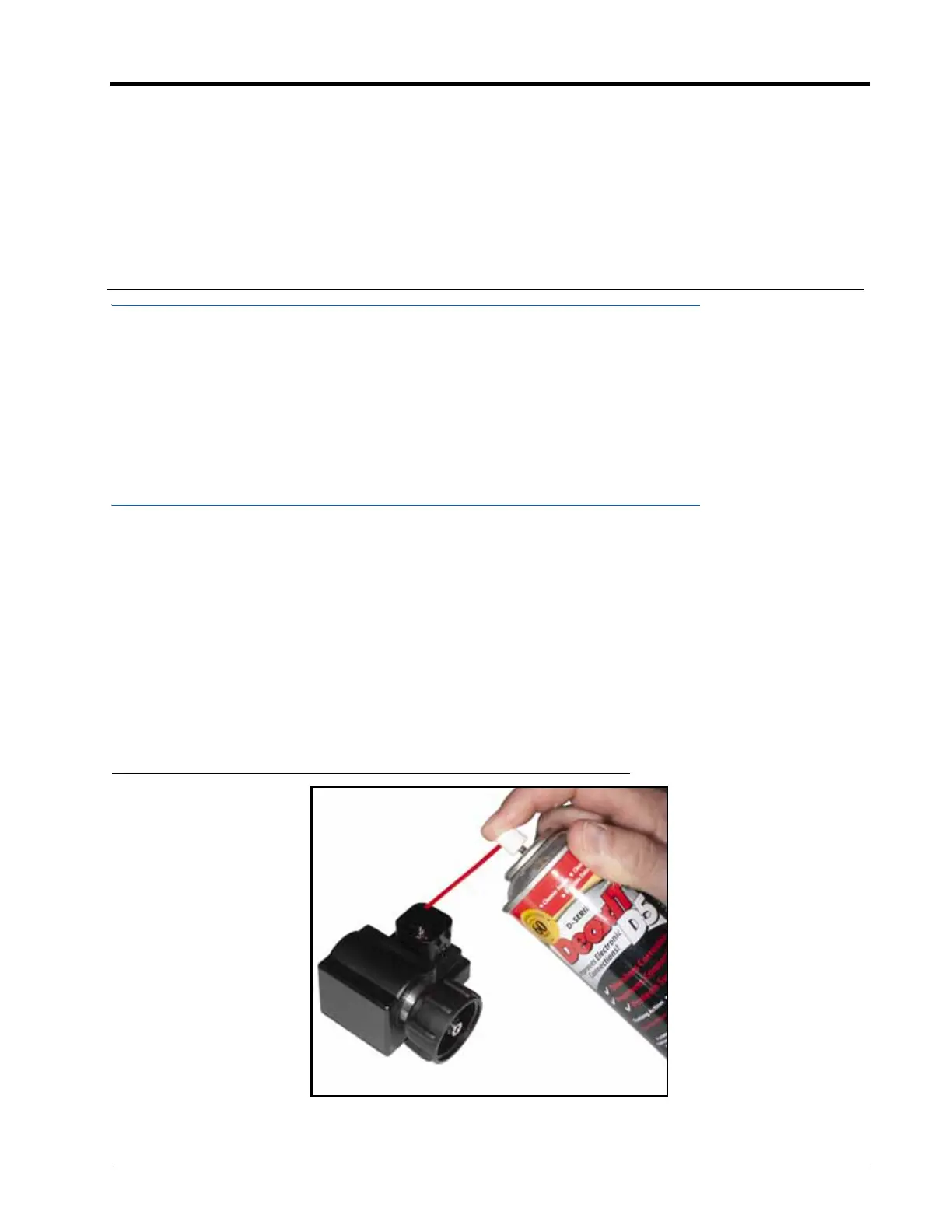

2. Spray the connection with a deoxidizing agent such as the recommended DeoxIT D5 (P/N 222-4001-006).

FIGURE 1. DeoxIT D5 Recommended

3. Clean contacts with a small wire brush (P/N 321-0000-477).

Loading...

Loading...