CHAPTER 9

96 RCM - Sprayer and AIM Command FLEX™ II Calibration and Operation Manual

5. Return to the Home page and note the existing volume in the tank.

6. Toggle at least one section switch and the master switch to the on position.

7. Use a small jumper wire (e.g. paper clip) to short the ground and signal sockets with a “short-no short” motion.

Each time the short is made, the total tank volume value should change by increments of one or more.

8. If the tank level does not decrease, disconnect the flow meter extension cable if installed and repeat this test at

the next connector closest to RCM - Sprayer ECU. Replace defective cable as required.

9. If all cables test good, replace the flow meter.

10. After testing is complete, re-enter correct meter cal value, units, and tank level.

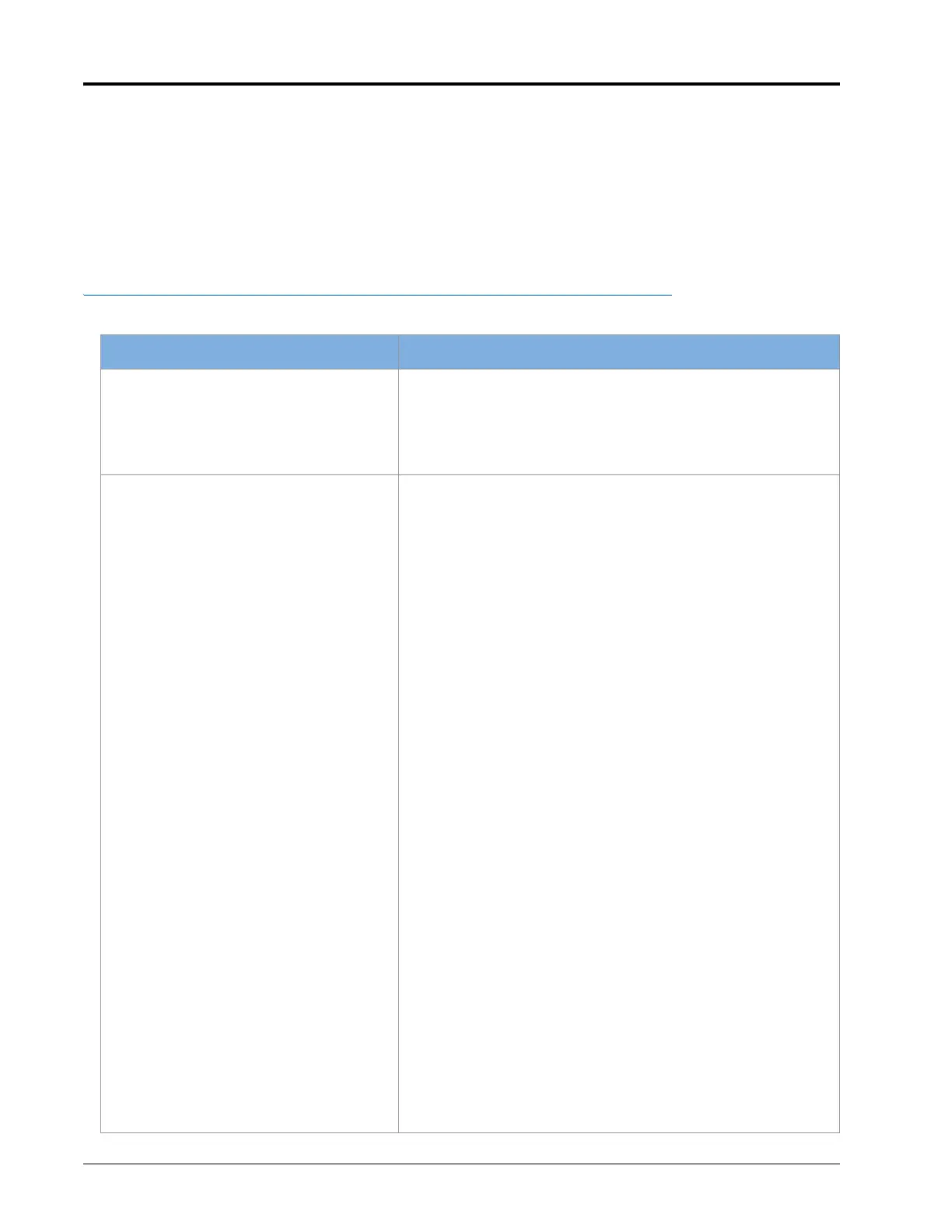

GENERAL TROUBLESHOOTING

Problem Action

Rate reads “0.” •Verify SPEED is registering accurately. If SPEED is zero, refer to

the UT display troubleshooting procedure.

•Verify TOTAL VOLUME is registering flow.

•Confirm the boom section status shows on the display changes

when section switches are activated in manual operation.

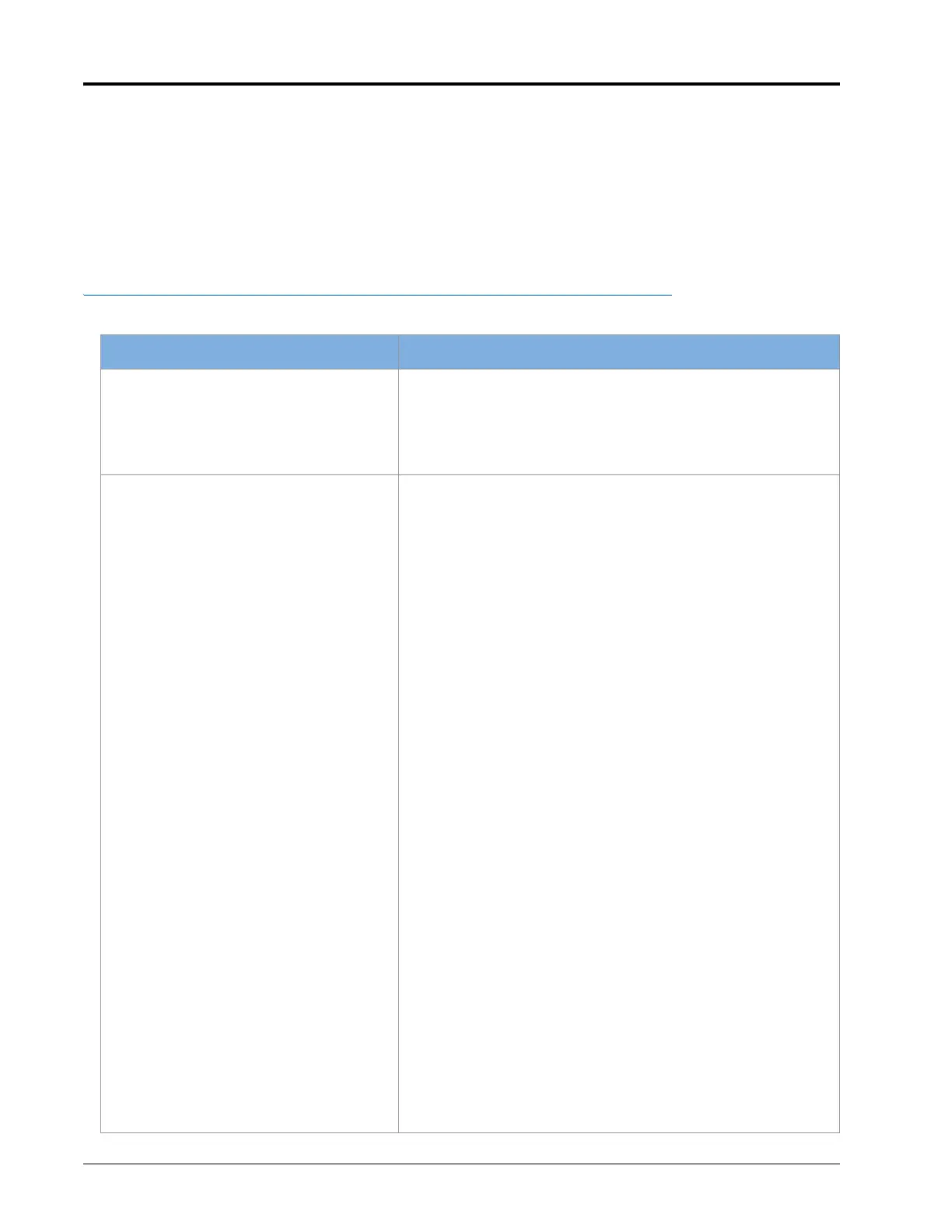

Pressure or rate inaccurate or unstable. •Verify that all calibration numbers and settings are correct.

Verify SPEED is registering accurately. If SPEED is inaccurate,

refer to the UT display troubleshooting procedure.

•Verify that all air has been removed from the boom by priming

the boom or recirculating. See “Automated Boom Prime” on

page 56 or “Boom Recirculation” on page 39 for more

information.

•Verify the pressure transducer is selected correctly.

•Verify Flow Meter calibration value and target rate is within

overall flow range.

•Verify control valve is operating correctly. Perform the PWM

health test described in “Perform the PWM Health Test” on

page 64 to inspect control range.

•In MAN (manual) operation, verify that Pressure and Rate

display holds constant.

•Confirm that boom section status shown on the display is not

changing.

•Verify ECU Inertial sensors are calibrated and performing

correctly. Refer to “Enable Turn Compensation” on page 38 or

“Turn Compensation Feature Inspection” on page 127 for more

information. Disable Turn Compensation if necessary to see if

pressure or rate stabilizes.

•Perform a self-test with boom master switches on to verify the

rate, pressure, and area/hour are steady while sitting still.

•In MAN (manual) operation, check low end and high end

pressure and flow range.

•In the Control Valve menu, decrease the Valve Response Rate if

pressure and rate oscillate greatly in AUTO mode. Increase the

valve response rate if control is unresponsive.

•In the Control Valve Settings menu, decrease the NCV response

sensitivity if system pressure and rate oscillate slightly in AUTO

mode. Increase if the system is unresponsive. Avoid setting both

the Valve Response Rate and NCV Response Sensitivity above

70.

Loading...

Loading...