4

System Setup: System Settings Tab 33

SYSTEM SETUP

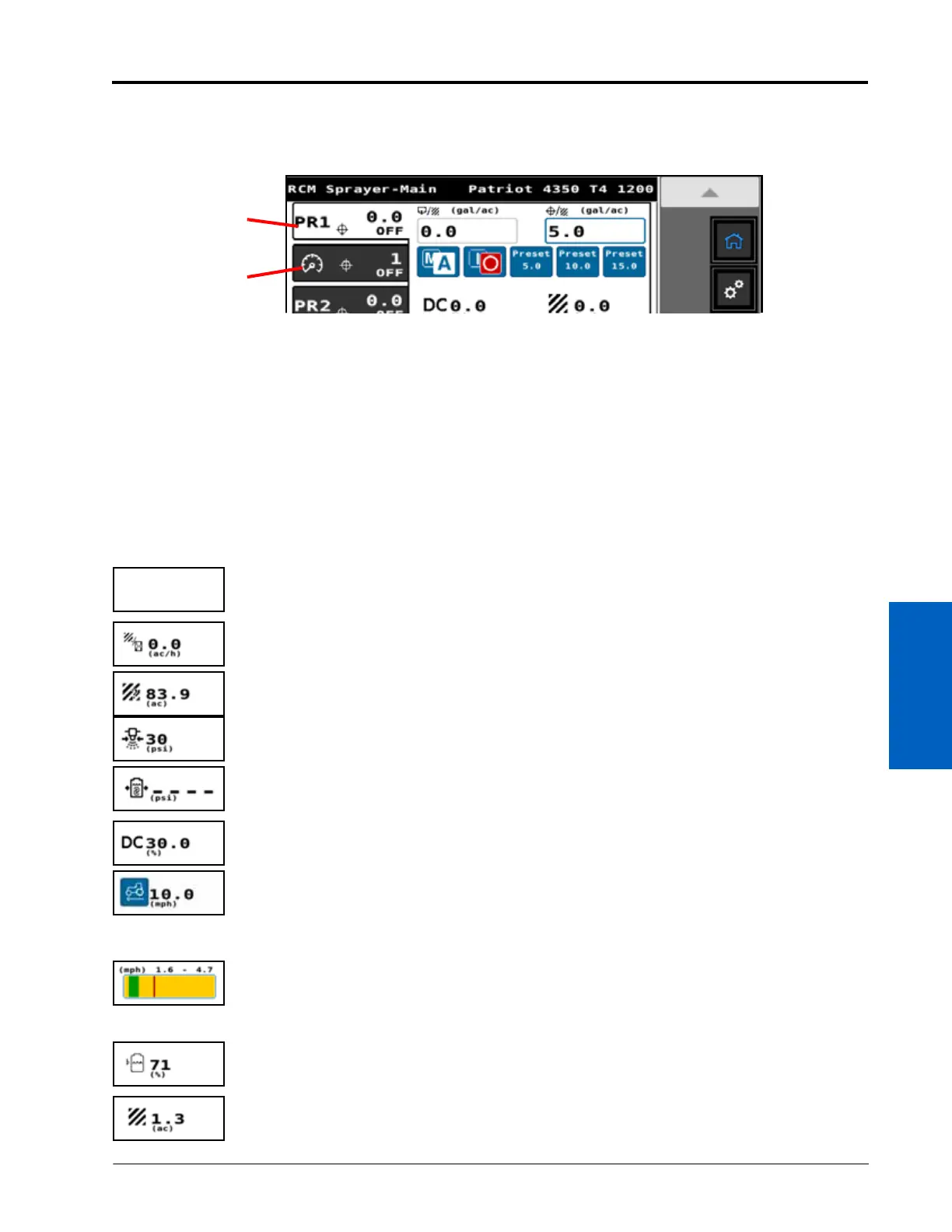

5. Use the Tab Selection buttons starting in the upper, left area of the Display Setup page to select which Home

page tab to customize.

NOTE: Slots for the Product 1 and Pressure tabs are reserved and will display readouts regardless of control

mode. Additional products (e.g. injection) will take up slots in the left column and bottom of the

“Display Setup” page.

6. Next, select the readout area and use the drop down list to set the readout to display in the selected area.

7. Enable Advanced Mode view to display up to 9 configurable readout area buttons. The default display mode is

the Basic view, which only allows 3 configurable readout buttons. Basic display view is not available when

chemical injection is configured.

8. Enable the Analog Gauges option to toggle product information on the rate control tabs as gauges.

9. Touch the Accept button in the lower, right corner of the page to accept the current readout selections and

return to the System Settings tab.

READOUT DESCRIPTIONS

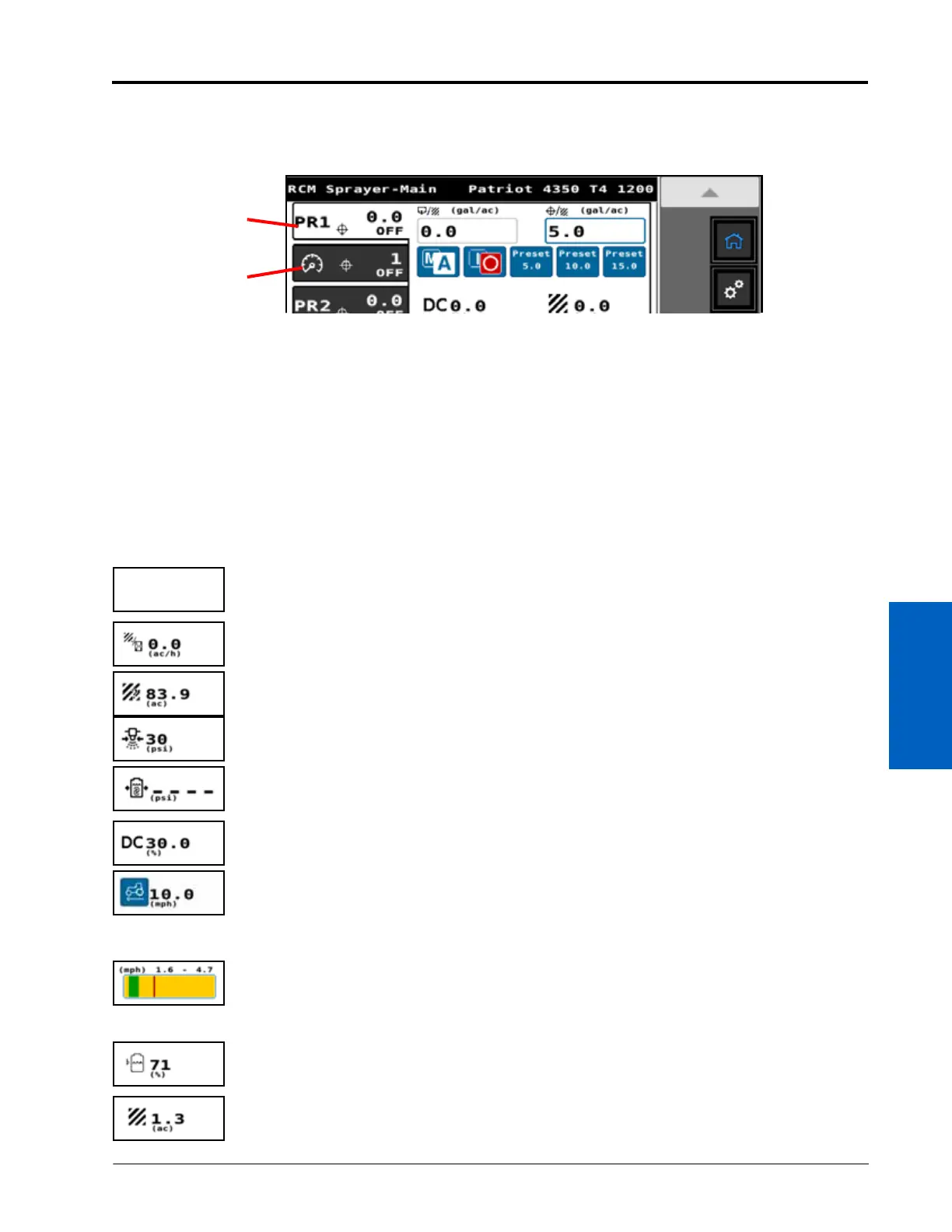

No Readout. Select the No Readout option to leave the selected area empty.

Area per Hour. Uses the implement width and current implement speed to calculate the rate at

which field area is covered.

Area Remaining. The field area remaining for the current job in progress.

Boom Pressure. Monitored pressure of the spray boom. This pressure is used as the control

system pressure for spraying and alarm conditions.

Sparge Pressure. The current pressure of the sparge or tank agitation system.

PWM Readout. The control duty cycle of the PWM control valve which controls the product

pump.

Speed Readout. The current speed over ground of the machine.

NOTE:Press and hold the machine button to enter a self test speed. Review the “Test Speed” on

page 26 for additional information on using this feature.

Recommended Speed. The optimal speed range to maintain the target rate and pressure

settings. If the equipment speed is outside of the optimal speed range, an alarm condition may

be encountered and the control system may be unable to maintain the desired application rate

or pressure.

Tank Level Percentage. Percentage of the total tank volume remaining in the product tank.

Area. The field area covered during the current field application.

Pressure Display

Tab

Product Rate

Control Tab

Loading...

Loading...