page 35 of 91 USB-QFLCII-14804/0

Inspection and

maintenance

WARNING

The wear and tear sensor does not eliminate the need for inspection

and maintenance at regular intervals!

Preventive and thorough inspection and maintenance is essential for the

safety of personnel working within range of the inlet isolation device. In

addition, preventive and thorough maintenance ensures the proper

operation of the system. Please have only qualified staff perform the

inspection, maintenance and service work!

Information and specifications regarding maintenance work and its intervals

stated in the operating instructions

are only recommendations. The

manufacturer does not have practical, long-term data under the specific

operating conditions of each customer. The information stated in the operating

instructions is to be supplemented with your own practical experience.

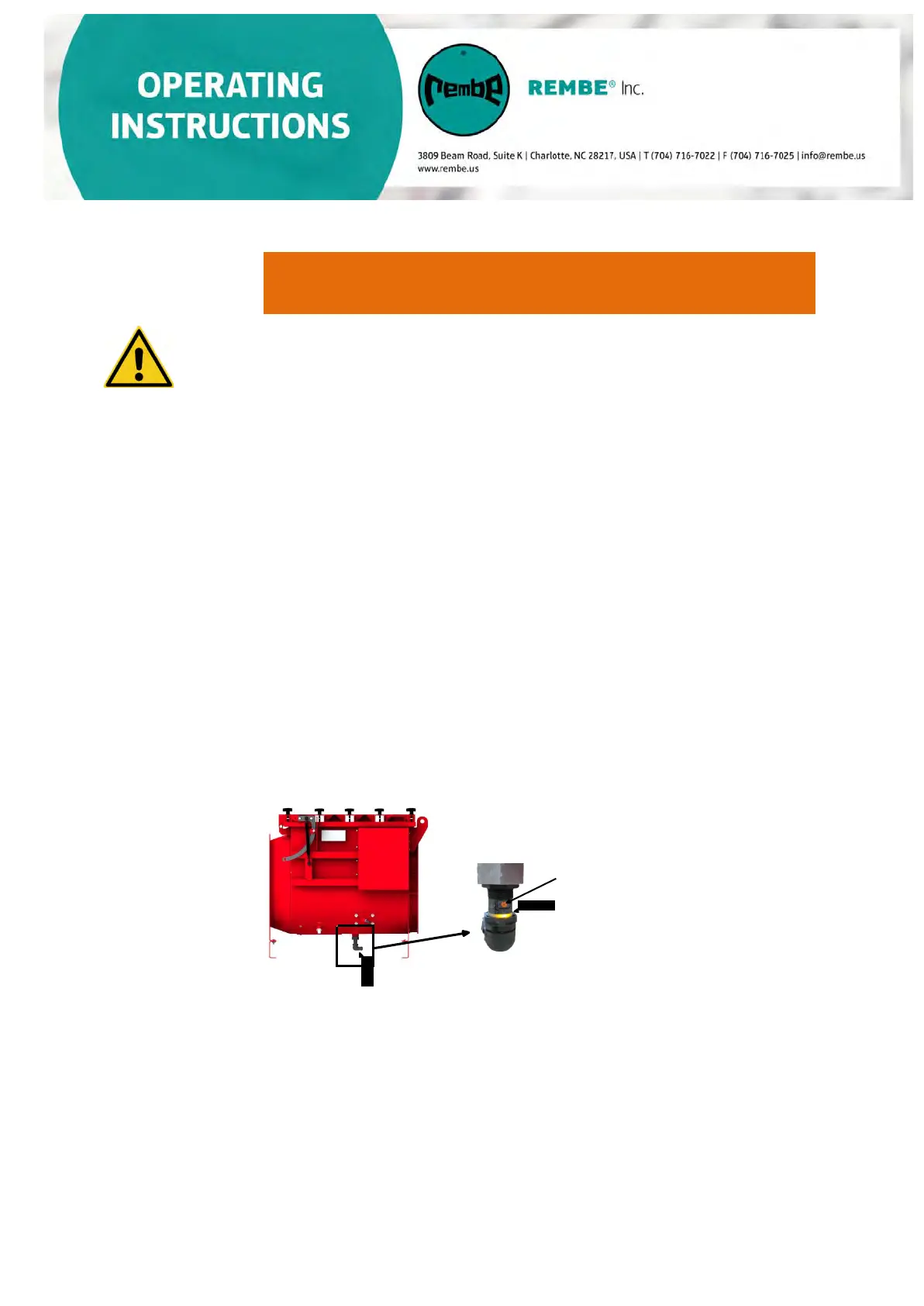

4.3 Optional Level sensor (optional sensor for

Q-FlapCompact II or Q-FlapCompact II Plus)

Level sensor Since deposits in the inlet isolation device cannot be excluded completely, there al-

ways exists a risk of fire and explosion in the flap. To reduce this risk, and to detect

deposits very early, the inlet isolation device may be equipped with a level sensor as

an option. The level sensor is attached below the flap blade and is active during

system operation.

Potentiometer

LED ring

Level sensor

The level sensor is a capacitive sensor which is able to detect deposits of

various process materials. The response behavior can be adjusted via a

potentiometer or individually with the process material (see Section 9.15 ,

Optional feature: adjusting the level sensor)

Response if sediments

detected

If the level sensor detects deposits, it will be indicated as a malfunction

message sent to the monitoring panel

. In addition, the LED ring will light

up, indicating the level sensor is detecting deposits. The system can

continue processing, without an emergency shutdown, but the system

must be shut down as soon as possible to determine the reason for the

deposits, correct any issues and to inspect/clean the inlet isolation device.

Loading...

Loading...