page 56 of 91 USB-QFLCII-14804/0

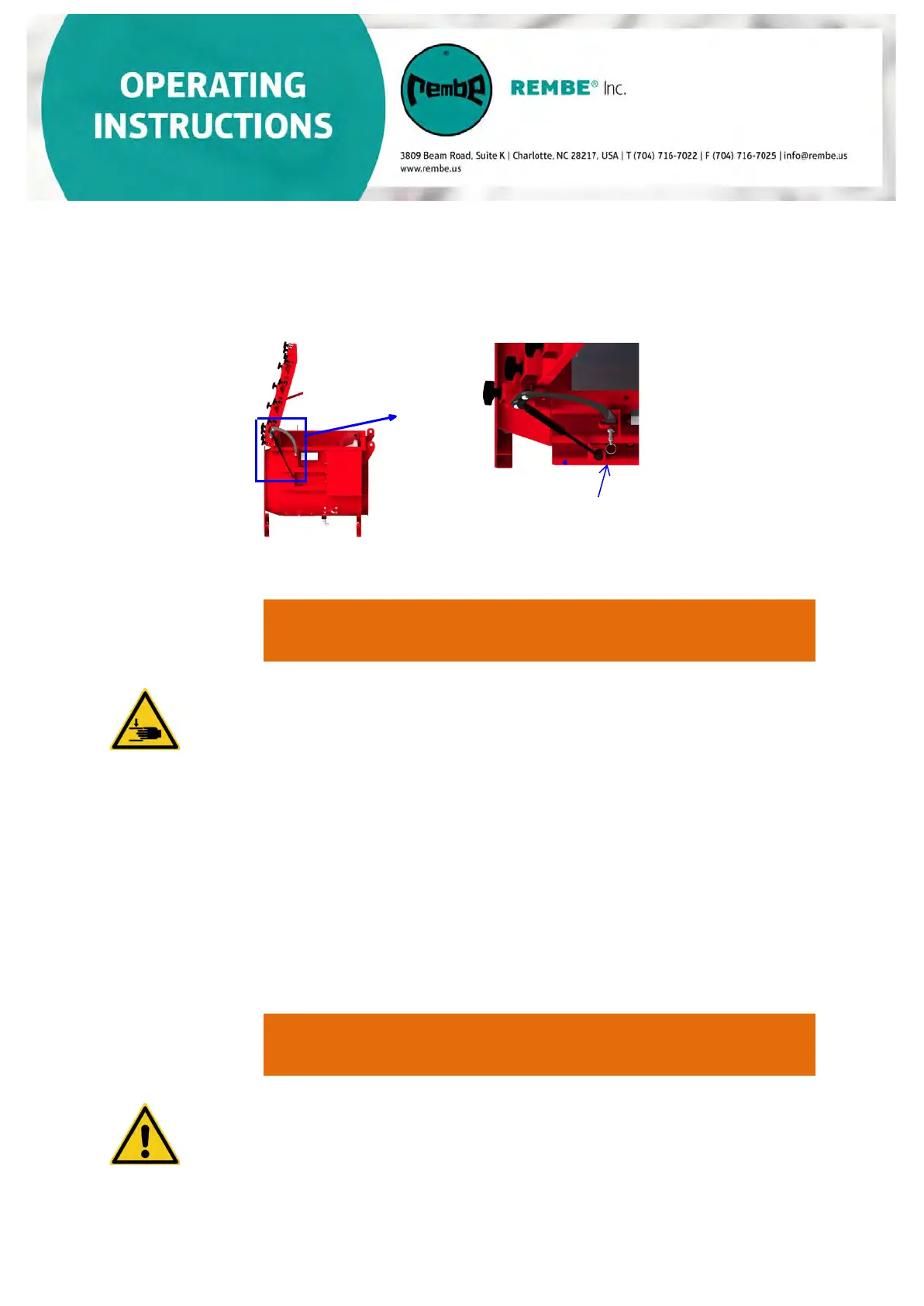

Inspection lid

closure with inlet

isolation devices

DN 630 and

larger

a) Hold the inspection lid with one hand on the handle which is attached out-

side.

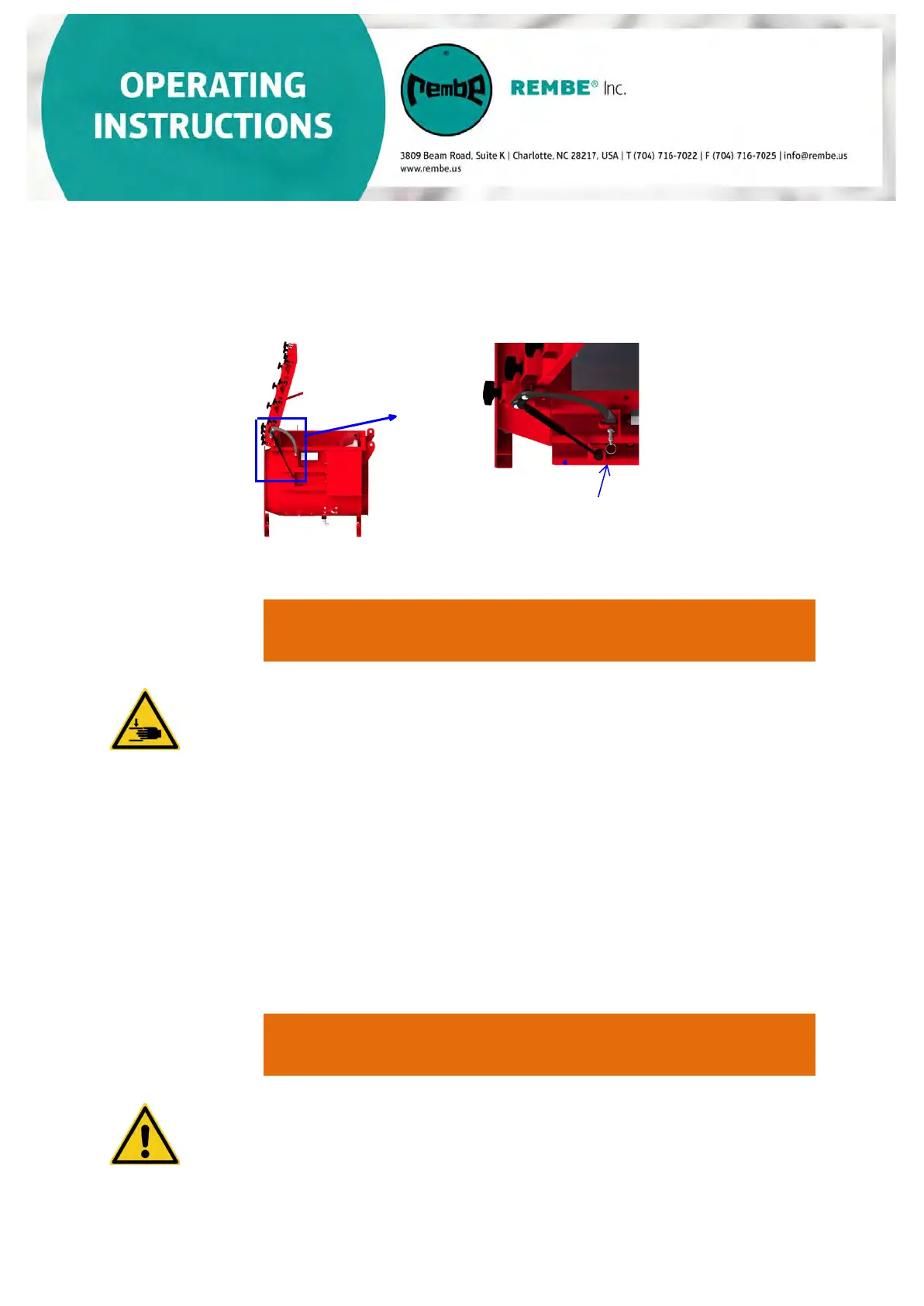

b) Pull the latch pin's ring to unlock the holding device.

Latch pin ring

c) Swivel the inspection door from opened position into closed position.

WARNING

Danger of crushing hazard due to inspection lid that is slammed closed.

Hold the inspection lid with one hand on the handle. Carefully swivel the inspection lid

into the closed position. Do not let the inspection door fall freely!

--------------------------------------------------------------------------------------------------------

d) Tighten the inspection lid locks (fasteners) clockwise

9.5 Inspection for wear and material deposits

Inspect the flap blade, the slanted pipe socket and the housing of the inlet isolation

device for deposits, material build up and wear. Please proceed as follows:

Ensure that the system is safely shut down and disconnected.

a) Open the inspection lid (see Section 9.4, Inspection lid opening and closing)

WARNING

Danger of head injuries due to protruding flap stopper when inspection

lid is opened!

Please watch out for the protruding flap blade stopper while working inside the inlet

isolation device. If necessary, equip the stopper with a bumper during the maintenance

process. The bumper must be removed prior to closing the inspection lid.

--------------------------------------------------------------------------------------------------------

Loading...

Loading...