page 63 of 91 USB-QFLCII-14804/0

WARNING

Crushing hazard/risk of injury to extremities from a falling/closing flap

blade!

Be

careful that all persons are some distance from the inlet isolation device

pipe socket, flap blade, locking unit and locking lever before dropping the flap

blade! Dangerous injuries could otherwise result.

--------------------------------------------------------------------------------------------------------

e) Wait until the flap rests on the pipe socket.

f) Try to lift the flap blade up without actuating the locking unit once again.

If the flap blade is not snapped in, or if it can be lifted up, the locking unit must

be readjusted (see Section 9.10, Adjustment of the locking unit).

g) Re-attach the cover of the locking mechanism with the corresponding

screws.

h) Close the inspection lid (see section 9.4, Inspection lid opening and closing).

9.10 Adjusting the locking mechanism

DANGER

If the locking mechanism is not adjusted correctly, there is a risk that

the flap blade will not lock tight and be kept closed in the event of an

explosion!

Explosion pressure/flame passage to upstream system areas could be the

result. Only trained personnel should adjust the locking mechanism!

--------------------------------------------------------------------------------------------------------

• Ensure that the system is disconnected safely.

• The locking mechanism settings should only be adjusted if, during

inspection and testing, the flap is not properly locking shut or if there is too

much distance between the locking unit and the locking lever.

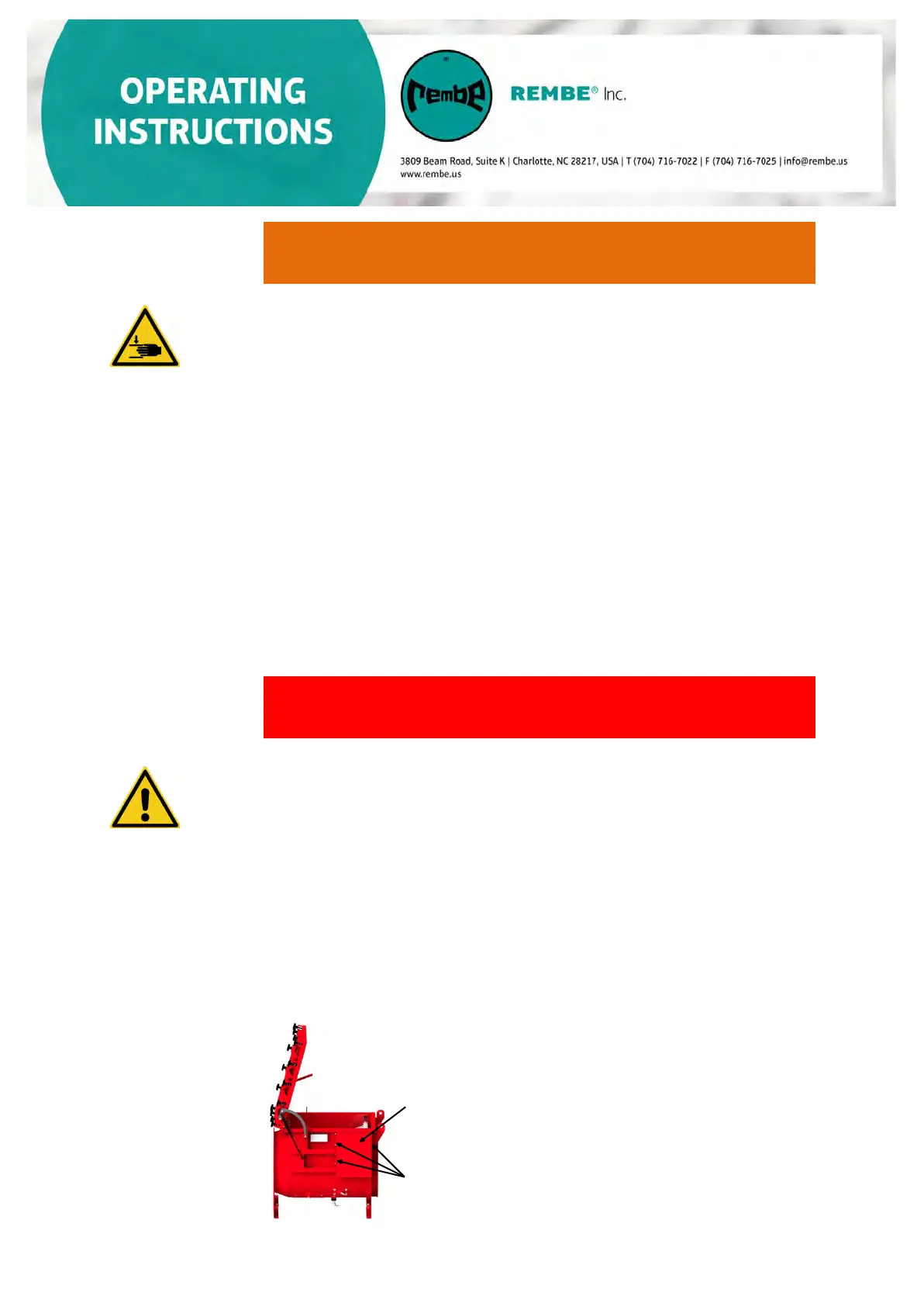

a) Remove the locking mechanism cover which is attached to the inlet isolation

device. All screws must be loosened and removed to remove the cover.

Cover of the

locking mechanism

Screws

Loading...

Loading...