Weighing Function

Purpose

The MA100/MA50 moisture analyzer

can be used for quick and reliable

determination of the moisture content

of materials of liquid, pasty and solid

substances according to the method of

thermogravimetry.

Notes on Models MA100C-0CE230V1,

MA100H-0CE230V1:

The models MA100C-0CE230V1,

MA100H-0CE230V1 are delivered with

initial calibration ex factory.

Do not exceed the given ambient

temperature range (+15° to +25°C) stated

on the manufacturer’s ID label. The

verifiable weighing program is designated

by the Q symbol in the display.

To ensure reliable measurements, allow

the analyzer to warm up before switching

to the verifiable weighing program.

An internal calibration/adjustment must

be conducted before each measurement

series (see page 54). This applies until

the analyzer has cooled down to ambient

temperature.

25

Operating the Moisture Analyzer

Basics

The moisture of a material is often

mistakenly equated with its water

content. In fact, the moisture of a

material includes of all the volatile

components which are given off when

the sample is heated, resulting in a

decrease in sample weight. Among

such volatile substances are:

– water

– fats

– oils

– alcohols

– organic solvents

– flavorings

– products of decomposition (when a

sample is overheated)

There are many methods to determine

the moisture content of a substance.

Basically, these methods can be divided

into two categories:

When absolute methods are used, the

moisture content is directly determined

(for example, as a weight loss registered

during the drying routine). These

methods include oven drying, infrared

drying, and microwave drying. All

three of these methods are thermogravi-

metric.

When deductive methods are used, the

moisture content is indirectly determined.

A physical property, which is related to

the moisture in the substance, is measured

(e.g., absorption of electromagnetic rays).

These methods include Karl-Fischer

titration, infrared spectroscopy, microwave

spectroscopy, etc.

Thermogravimetry is the process of deter-

mining the loss of mass that occurs when a

substance is heated. In this process, the

sample is weighed before and after being

heated, and the difference between the

two weights is calculated.

In a conventional drying oven, circulating

hot air warms the sample from the outside

to the inside. Efficiency is lost during

drying because as the moisture evaporates,

it cools the sample surface.

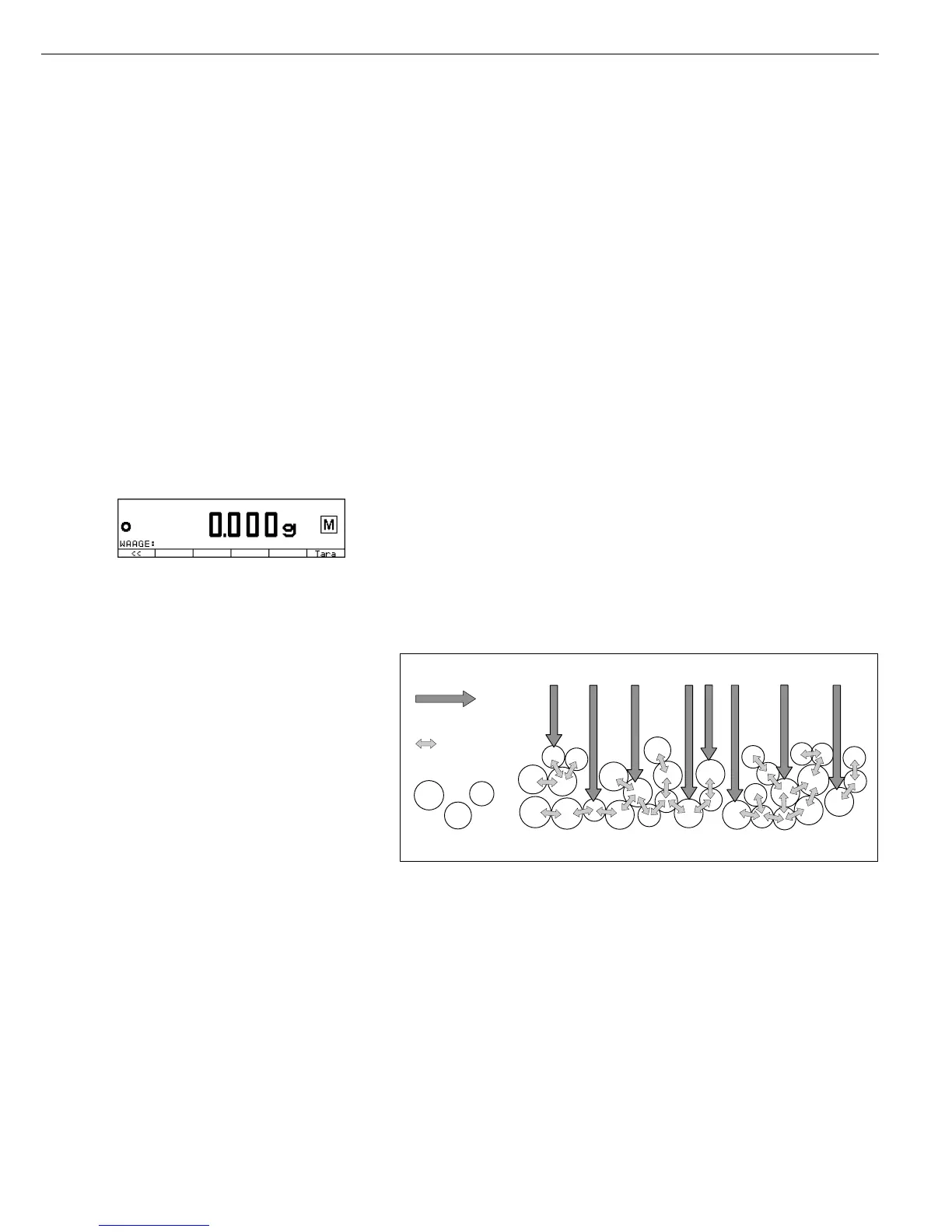

By contrast, infrared rays (IR rays) pene-

trate a sample without being impeded.

Having reached the interior of a sample,

they are converted into heat energy, which

stimulates evaporation, thus drying the

sample. A small part of the IR rays is

reflected from the surface of the substance.

Loading...

Loading...