2.19

configuration analyser. These include needle valves to regulate the flow through the

Gfx transducer. The flow through the Gfx transducer should not exceed 2.0 l/min.

Where the optional needle valves are not used then external provision to limit the

sample flow to 2.0 l/min should be provided.

The dual stream analyser configuration may only be used with external calibration

valves. It is not possible to use the optional internal calibration manifold in this

configuration.

2.10 Sample gas condition

WARNING

C Verify that connections are leak free at full operating pressure before

applying sample or calibration gases. These gases may be toxic or

asphyxiant.

C Consideration should be given to the toxicity and asphyxiant nature of

the sample gas when selecting a vent location.

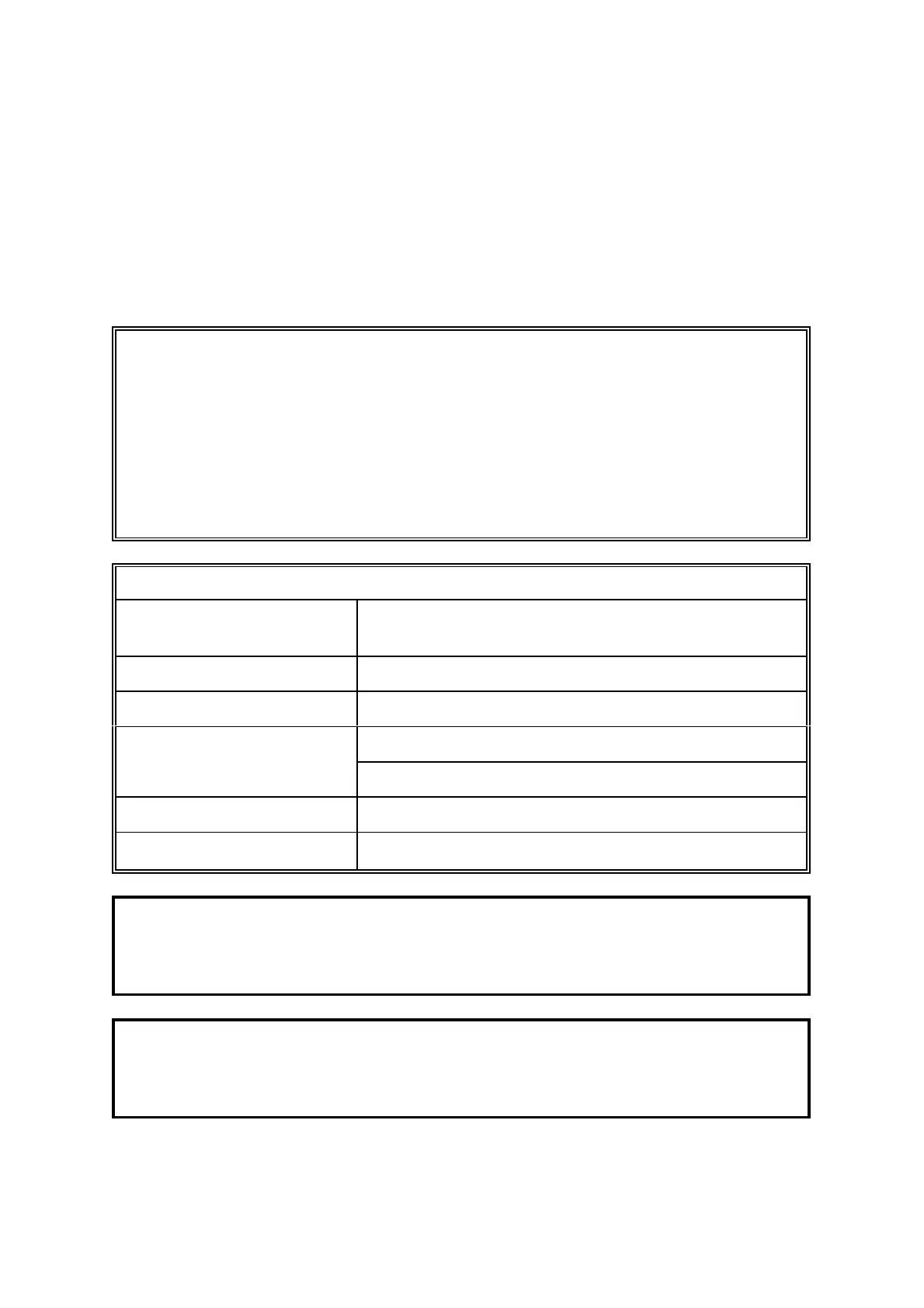

Table 2.9 Sample gas conditions

Sample pressure 1-5 psig / 7 - 34 kPag. Externally regulated to

provide correct transducer flow rate.

Temperature Up to 60 °C

Conditions Oil free, non-corrosive, non-condensing

Flow rate Paramagnetic transducer 50-250 ml/min

Gfx transducer 500-1500 ml/min

Particulates Filtered to remove particles exceeding 1 µm

Dew point 5 °C / 9 °F below lowest ambient temperature

CAUTION

Do not exceed the rated flow or pressure as transducer damage may result! This

is especially important for paramagnetic transducers!

NOTE

For best performance the flow, or pressure, supplied to the analyser should be

kept at a constant value for both normal sampling and for calibration gas input.

Loading...

Loading...