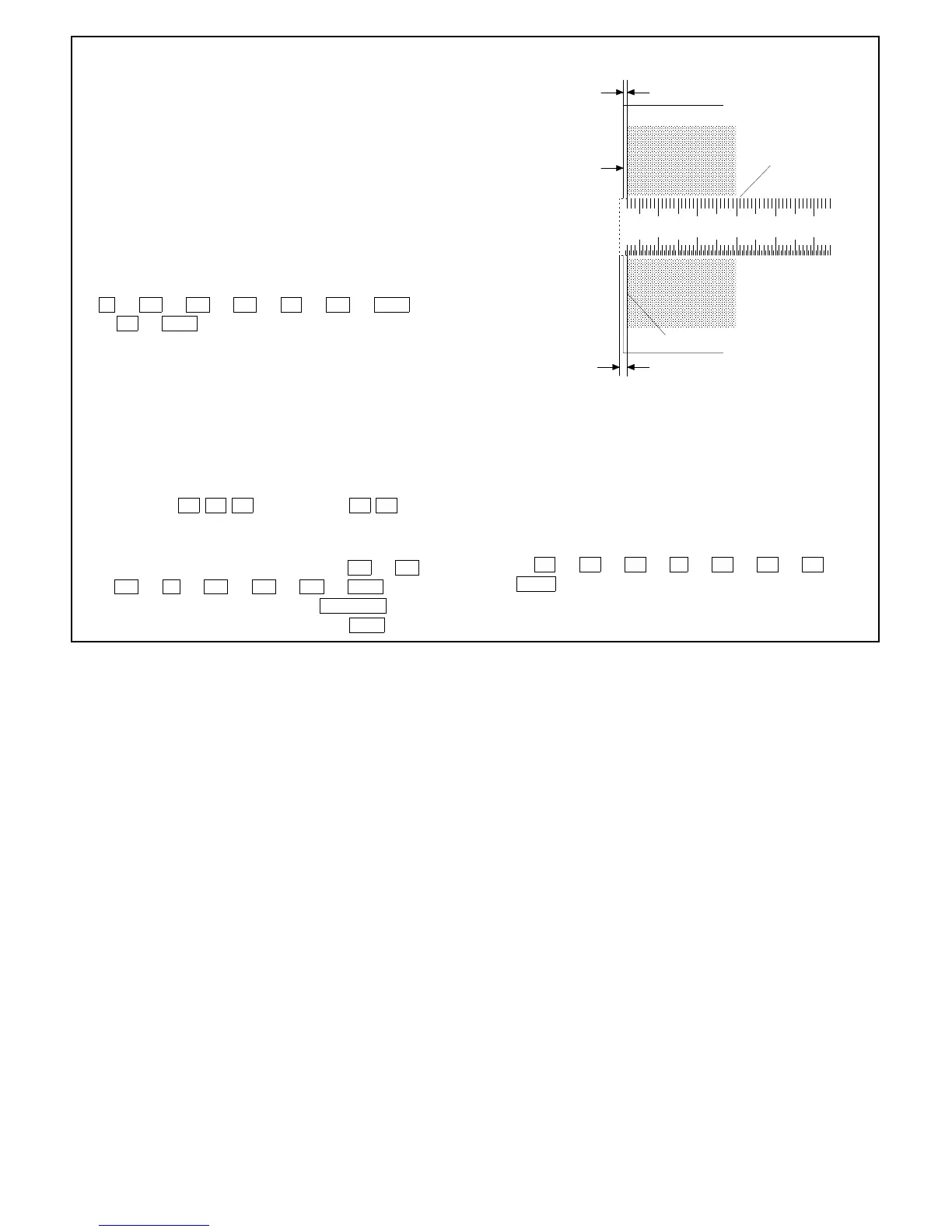

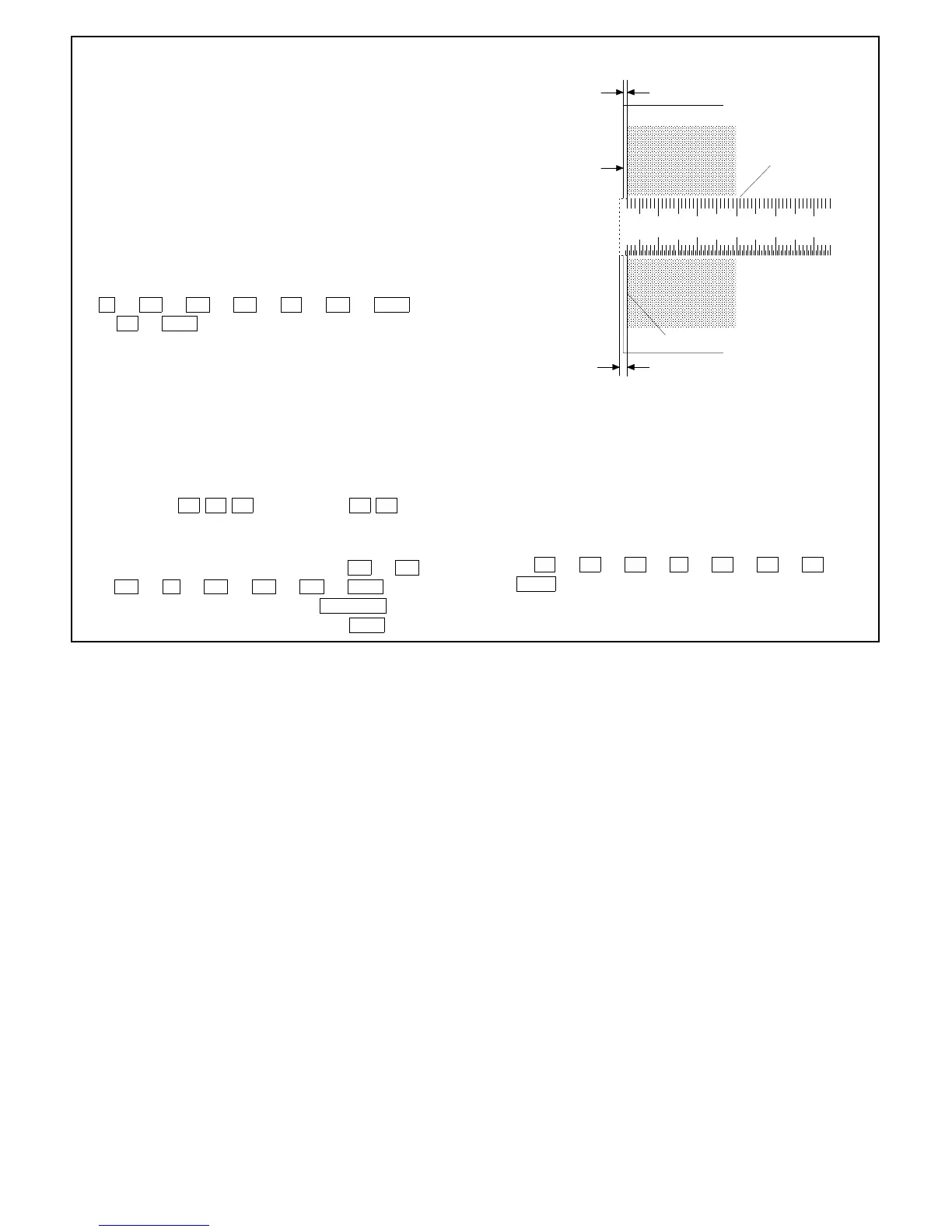

G Take a full-size copy and check if the image loss and the void

area meet the following standards:

(Standard value)

Image loss: 0 ~ 4 mm

Void area: 1 ~ 4 mm

H Press the clear key to clear Simulation 50-01.

Note: After changing the RRC-A and RRC-B settings, al-

ways adjust the void area of copy end.

(When using Simulation 50-02)

The key and indicator functions in Simulation 50-02 are the same

as those in Simulation 50-01.

Simulation 50-02 permits the values of L1 and L2 to be directly

input and the end adjustment to be easily performed.

Adjusting Procedure

1 Set a scale on the original table.

2 C → =↵ → 0/◊ → =↵ → 5 → 0/◊ → PSW

→ 2 → PSW to enter the Simulation 50-02 mode.

The machine starts warm-up operation.

3 Display example:

LEAD EDGE IMAGE POSITION ADJUSTMENT (CALCULATION FORMULA)

L1 L2: VOID:

• L1: Lead edge deviation at 200% magnification (FFF mm:

3-digit)

• L2: Lead edge deviation at 100% magnification (✕✕✕ mm:

3-digit)

Indication example of copy quantity indicator

42.5 mm → 4 2 5 → indicated as 2 5

4 Using the scrol display key and ten keys, set both A and B

values to 0 and take a copy at magnification 100% and 200%

respectively.

• An 100% copy can be taken by typing 0/◊ → 0/◊ →

0/◊ → ➡ → 0/◊ → 0/◊ → 0/◊ → PSW .

• A 200% copy can be taken by typing ENLARGE →

(After the lens moves, ready lamp ON) → PSW .

5 Measure the distance from the paper end to image(scale) end of

the 200% and 100% copy, and using the scrol display key and

the ten keys, type the L1 and L2 values. Type all three digits.

The RRC-A and RRC-B values of Simulation 50-01 are automat-

ically calculated and stored in memory.

Input Procedure

Assuming the L1 is 25.4 mm and L2 is 15.0 mm:

After checking that the last digit of the magnification indicator is

A, 2 → 5 → 4 → ➡ → 1 → 5 → 0 →

PSW .

6 Adjust and check the deviation, image loss and void area in the

same manner as in case of Simulation 50-01.

10 20 30 40

50

Void area

1~4mm

Paper end

Scale image

Solid edge

Image loss

0~4mm

Full-size(100%) copy

7 – 17

Loading...

Loading...