3 Functions Issue 07/04

MICROMASTER 420 Operating Instructions

72 6SE6400-5AA00-0BP0

3.5.5 Commissioning the application

After the motor – drive inverter combination was commissioned using the quick or

series commissioning, in the following step parameters should be adapted and set

according to the technological requirements. As an example, the following points

should be considered:

Functional requirements of the drive inverter (e.g. process control with PID

controller)

Limit values

Dynamic requirements

Starting torques

Load surge requirement

Overload

Diagnostics

If the application includes a function, which is not covered by the quick or series

commissioning, then the following sections of the function description or the

parameter list should be considered.

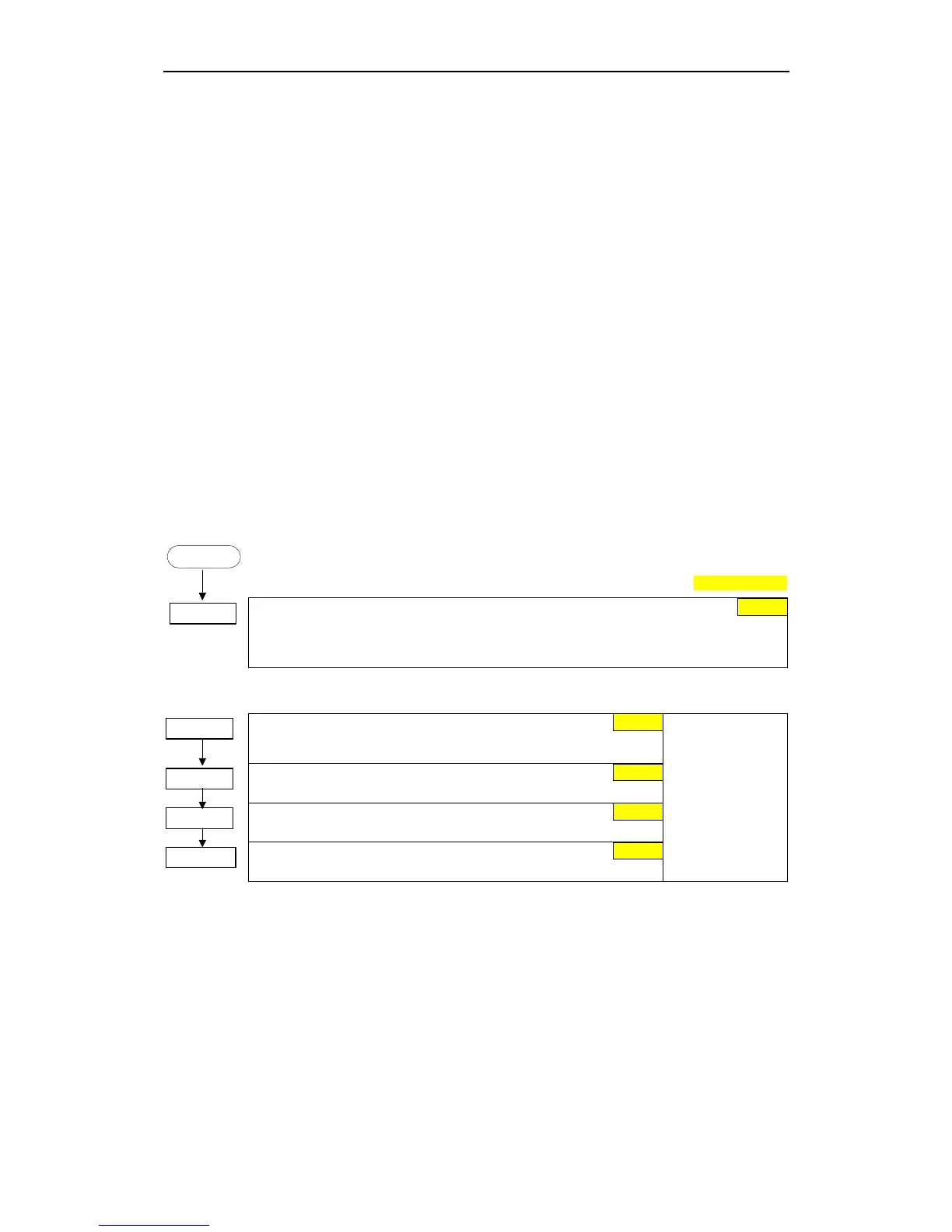

Adapting the drive inverter to the application

The parameters designated with * offer more setting possibilities than are listed

here. Refer to the parameter list for additional setting possibilities.

START

Factory settin

P0003 = 3

User access level *

1 Standard (Allows access into most frequently used parameters)

2 Extended (Allows extended access e.g. to inverter I/O functions)

3 Expert (for expert use only)

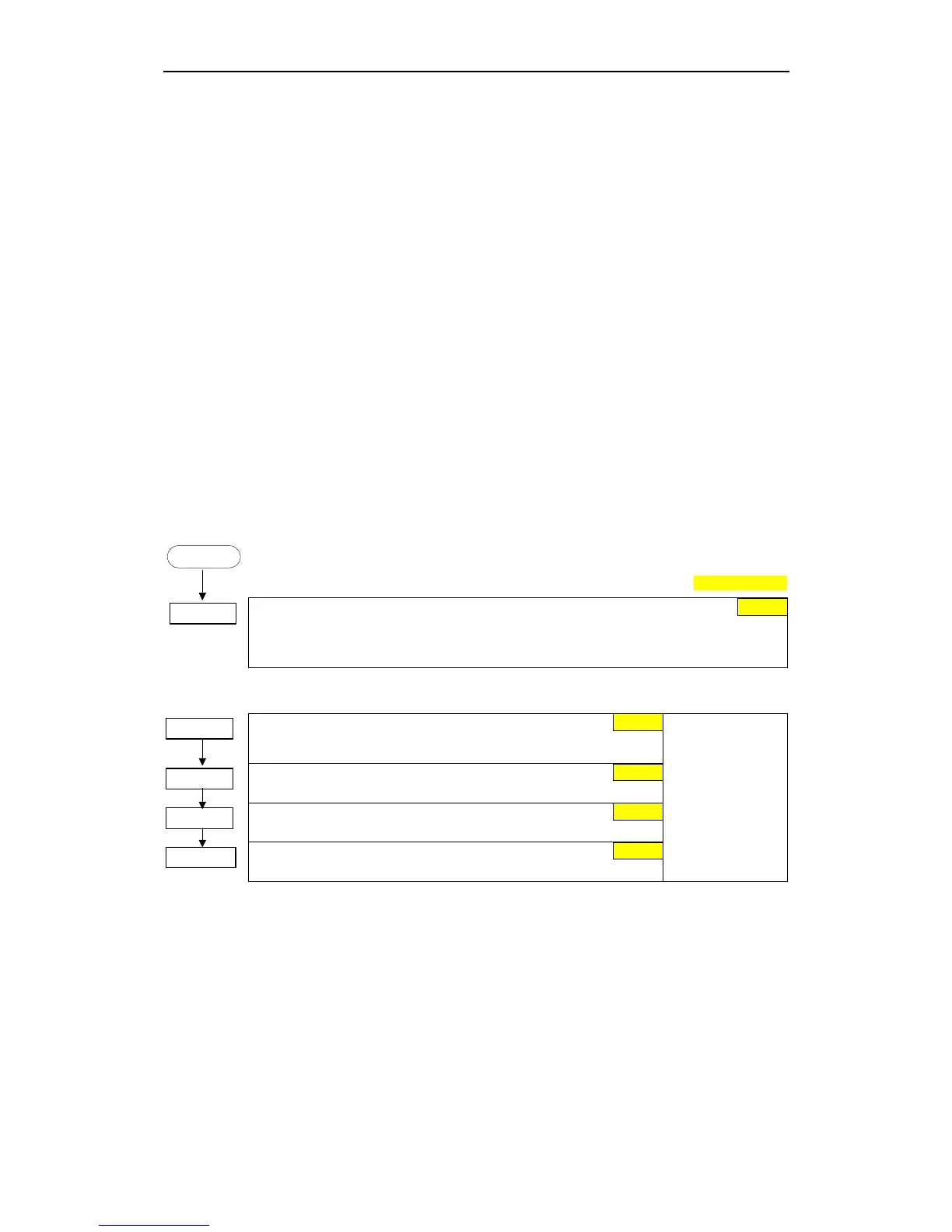

3.5.5.1 Serial Interface (USS)

P2010 =...

USS baud rate

Sets baud rate for USS communication.

P2011 =...

USS address

Sets unique address for inverter.

P2012 =...

USS PZD length

Defines the number of 16-bit words in PZD part of USS telegram.

P2013 =...

USS PKW length

Defines the number of 16-bit words in PKW part of USS telegram.

Possible

Settings:

3 1200 baud

4 2400 baud

5 4800 baud

6 9600 baud

7 19200 baud

8 38400 baud

9 57600 baud

1

6

0

2

127

Loading...

Loading...