Functions

2.7 Motor Protection (Motor Starting Protection 48, Motor Restart Inhibit 66, Load Jam Protection)

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

123

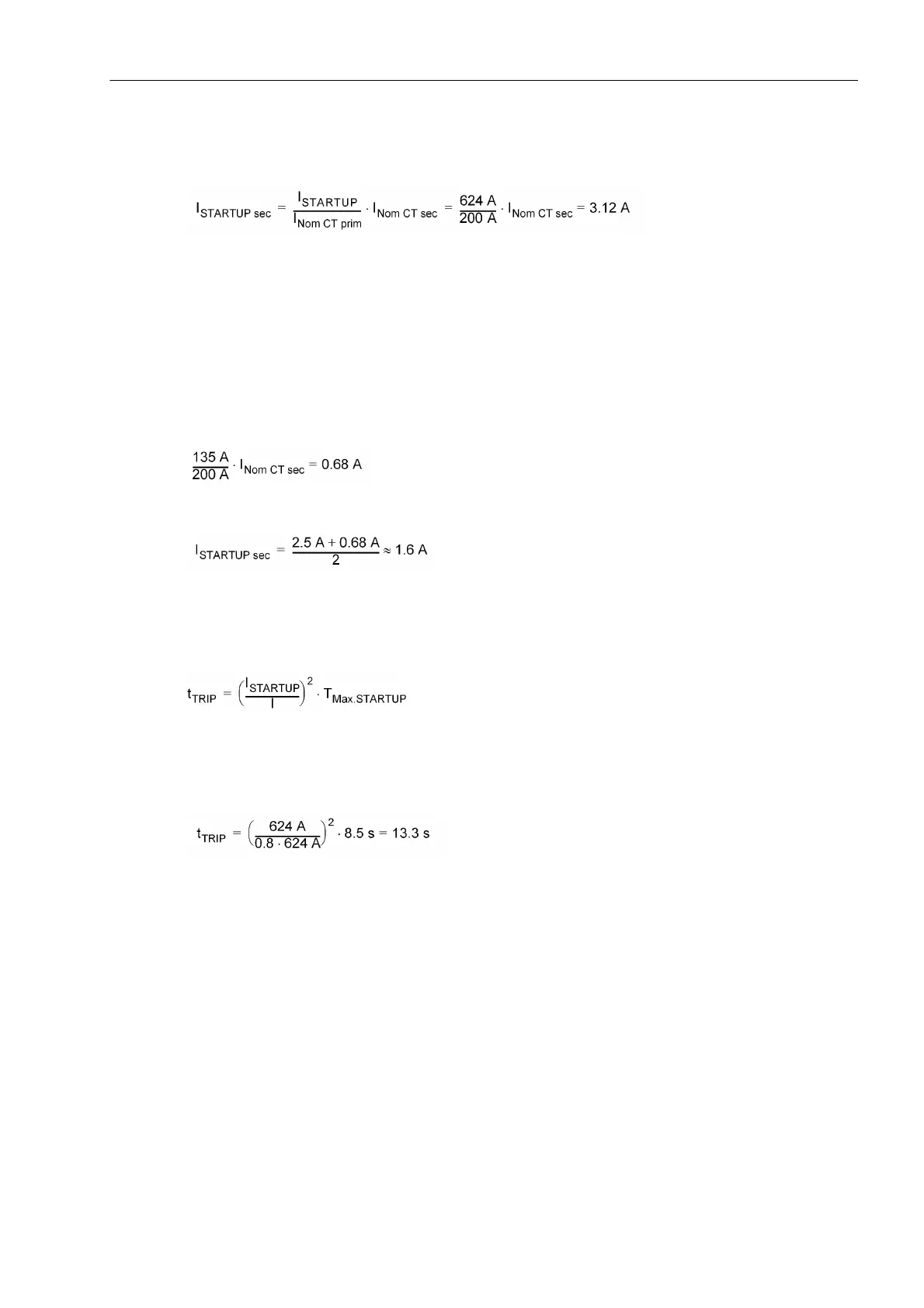

The setting for address STARTUP CURRENT (I

STARTUP

) as a secondary value is calculated as follows:

For reduced voltage, the startup current is also reduced almost linearly. At 80 % nominal voltage, the startup

current in this example is reduced to 0.8 · I

STARTUP

= 2.5.

The setting for detection of a motor startup must lie above the maximum load current and below the minimum

start-up current. If no other influencing factors are present (peak loads), the value for motor startup I MOTOR

START set at address 1107 may be an average value:

Based on the Long-Term Current Rating:

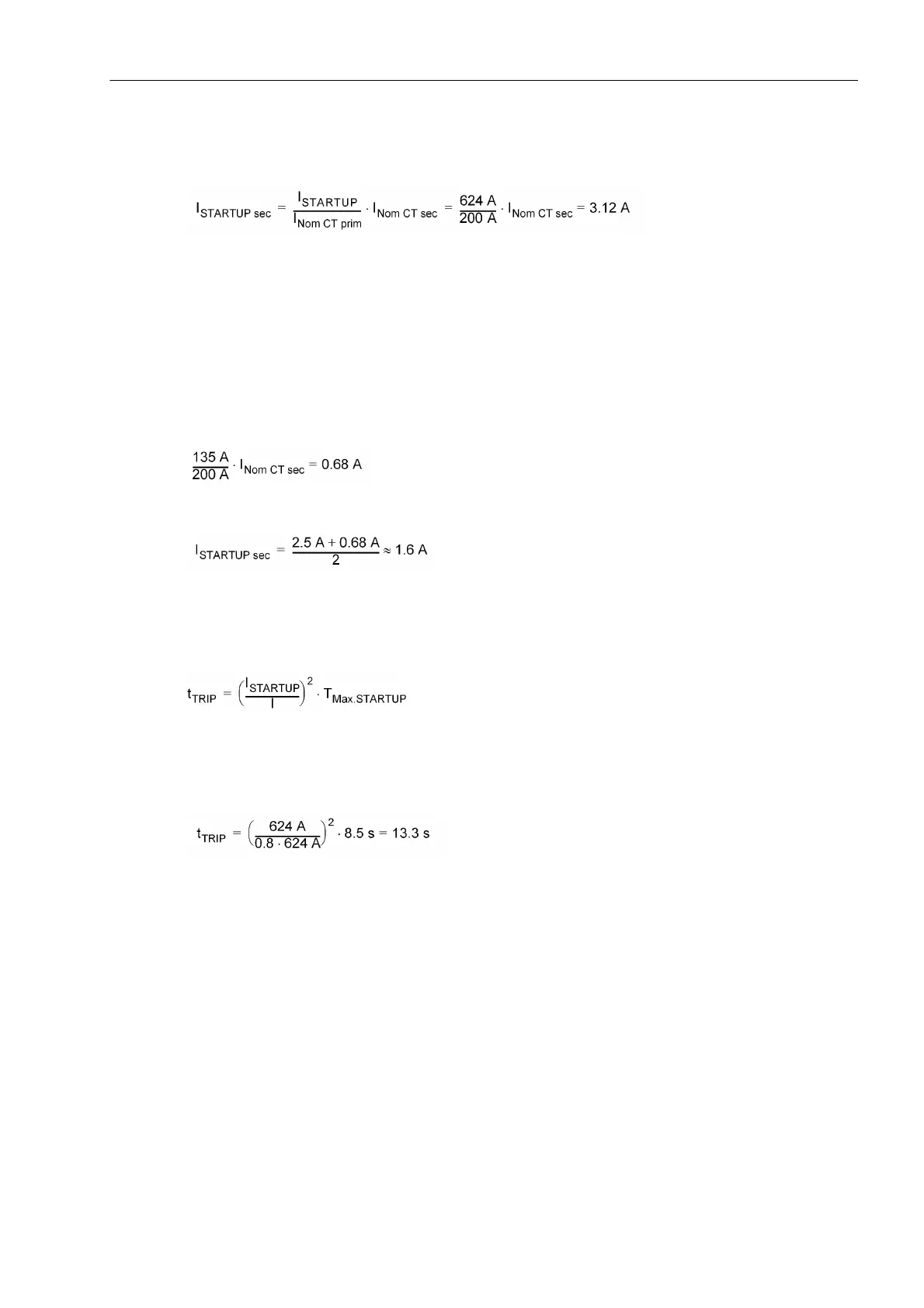

For ratios deviating from nominal conditions, the motor tripping time changes:

At 80% of nominal voltage (which corresponds to 80% of nominal starting current), the tripping time is:

After the time delay (4104 LOCK ROTOR TIME) has elapsed, the binary input becomes effective and generates

a trip signal. If the locked rotor time is set just long enough that during normal startup the binary input „>48

Rot. locked“ (FNo. 6805) is reliably reset during the delay time LOCK ROTOR TIME, faster tripping will be

available during motor starting under locked rotor conditions.

Loading...

Loading...