Mounting and Commissioning

3.3 Commissioning

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

317

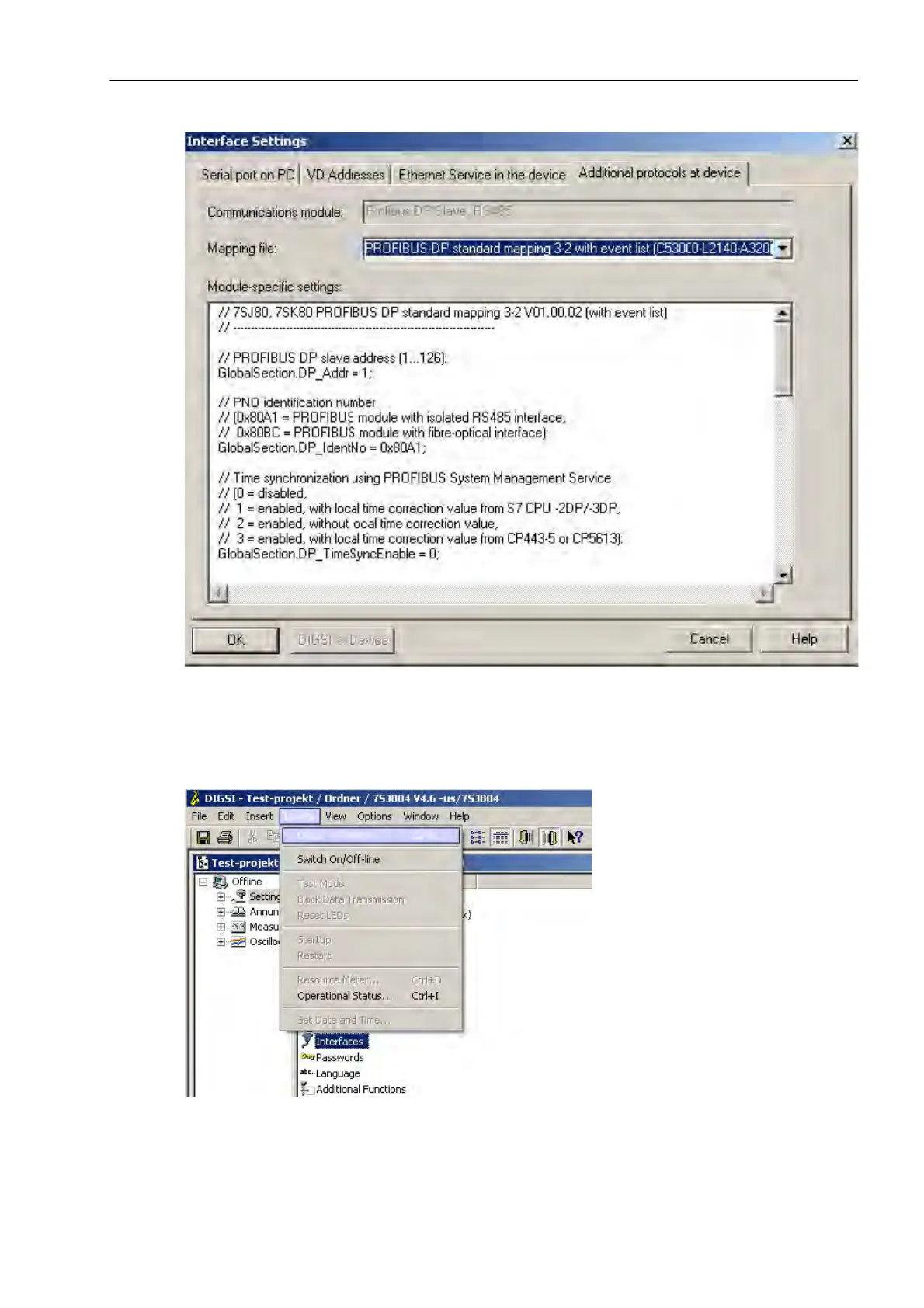

Figure 3-25 Module-specific settings

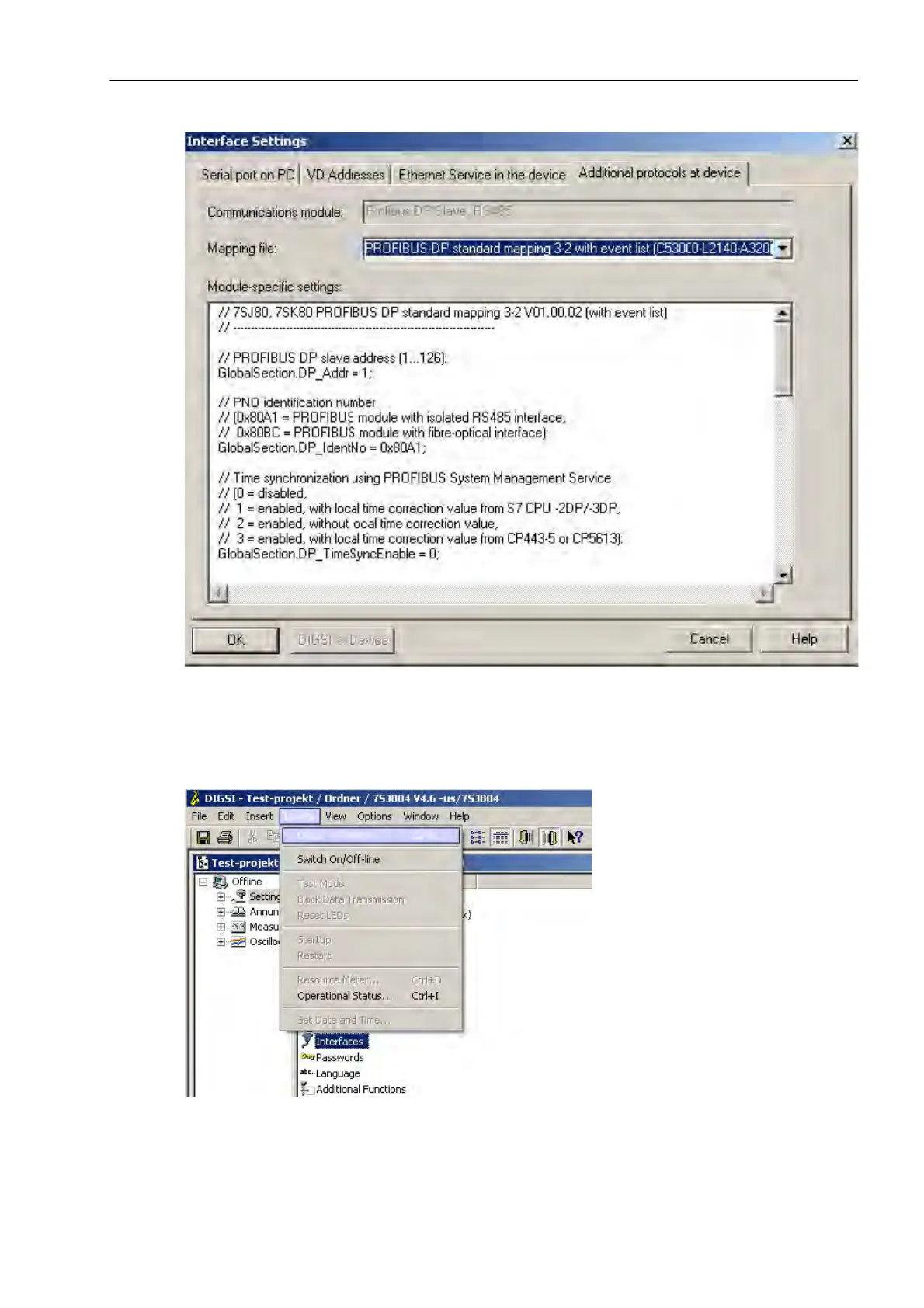

Then, transfer the data to the protection device (see the following figure).

Figure 3-26 Transmitting data

Loading...

Loading...