3.3 Commissioning

417

7UT613/63x Manual

C53000-G1176-C160-2

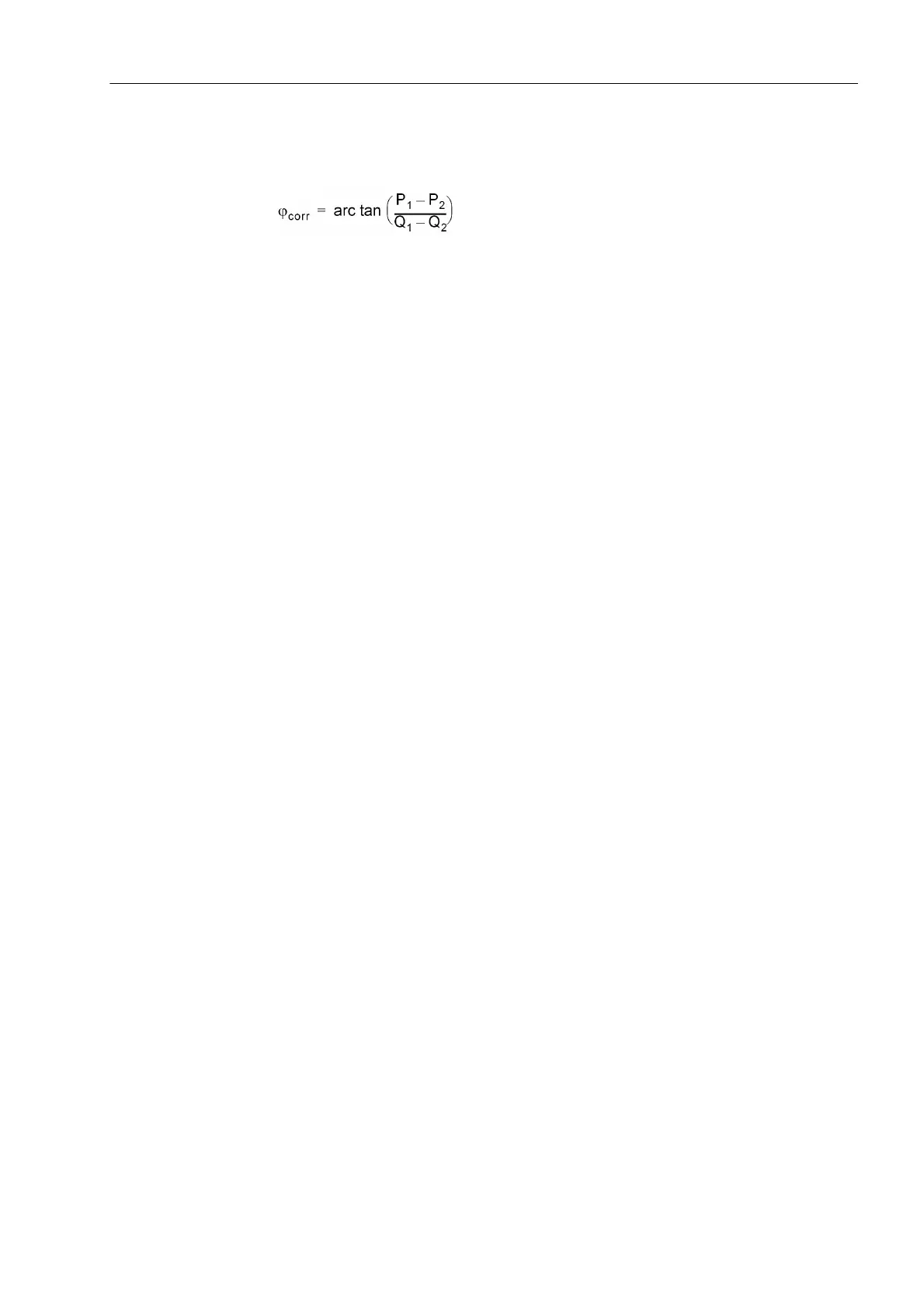

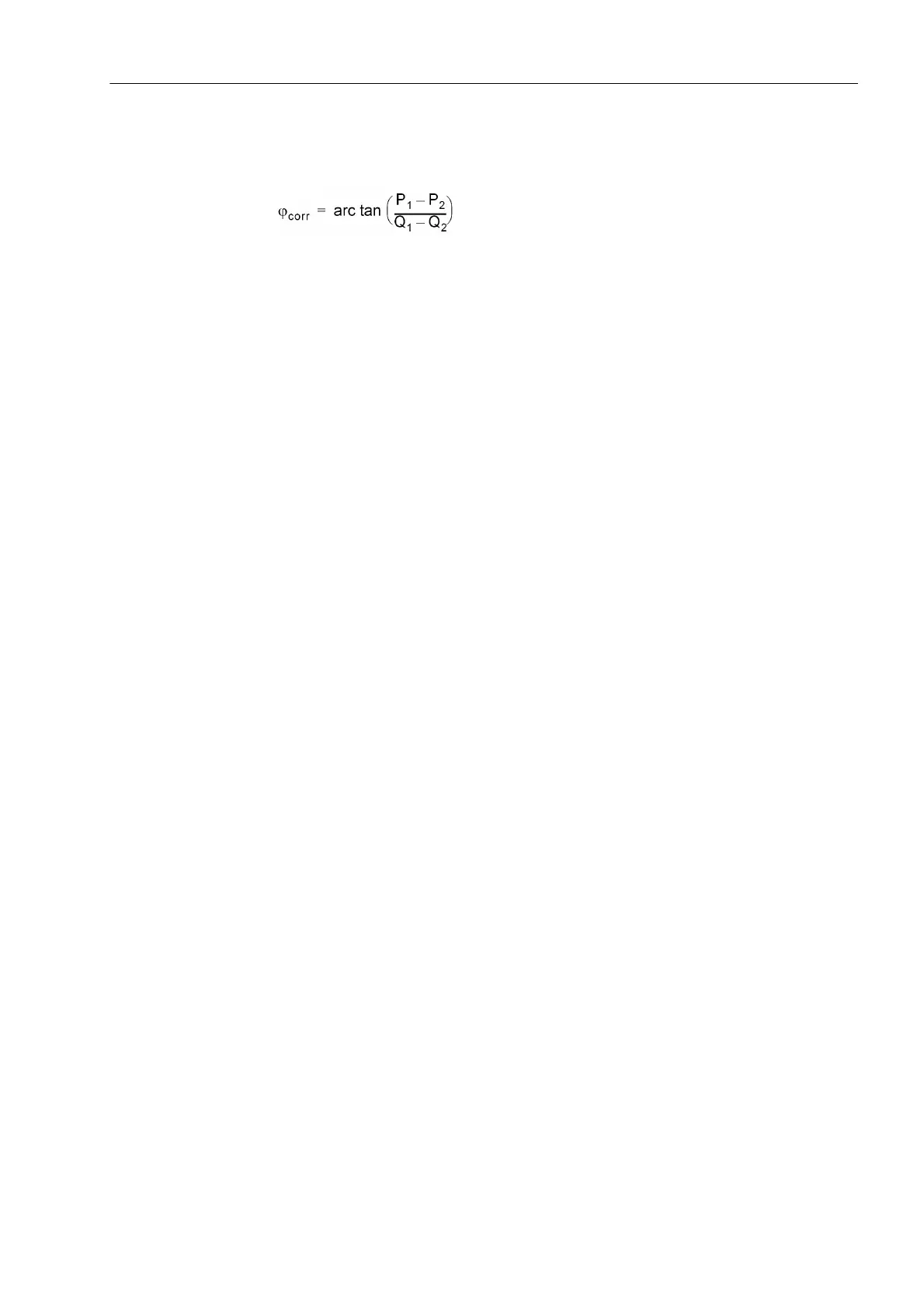

The read-out measured values P1 and P2 are now used to carry out CT angle error

correction: First calculate a correction angle from the measured value pairs according

to the following formula:

The power values must be inserted with their correct polarity as read out! Oth-

erwise faulty result!

This angle ϕ

corr

is entered with reversed sign as the new correction angle under

address 803 CORRECT. U Ang:

Setting Value CORRECT. U Ang =–ϕ

corr

Reverse Power Pro-

tection Setting for

Generator

If an exact reverse power protection is used on a generator, you can now calculate

the optimum setting value. If a generator is connected with the network, reverse power

can be caused by

• closing of the regulating valves,

• closing of the stop valve

For the first case, the motoring power has already been determined from the pre-

scribed measurements. As the pickup value of the reverse power protection corre-

sponds to approximately half the motoring power, set the pickup value of the reverse

power protection P> REVERSE in address 5011 (in Watt) or 5012 (referred to the

nominal current of the generator) to a quarter of the sum of the read-out measured

values P

1

and P

2

– also with negative sign –.

Because of possible leakages in the valves, the reverse power test should be per-

formed with emergency tripping.

• Start up generator and synchronise with network, if not yet done.

• Close stop valve.

• From the operational measured value for the active power, the motoring power

measured with the protection device can be derived.

• If that value should be found to be unexpectedly less than the reverse power with

the stop valves closed, 50% of that value should be taken as the setting for the

reverse power protection.

• Re-open stop valve.

• Shut down the generator.

3.3.13 Testing User-defined Functions

The device has a vast capability for allowing functions to be defined by the user, es-

pecially with the CFC logic. Any special function or logic added to the device must be

checked.

A general procedure cannot in the nature of things be specified. Configuration of these

functions and the set value conditions must be actually known beforehand and tested.

Especially, possible interlocking conditions of the switching devices (circuit breakers,

isolators, grounding electrodes) must be observed and checked.

Loading...

Loading...