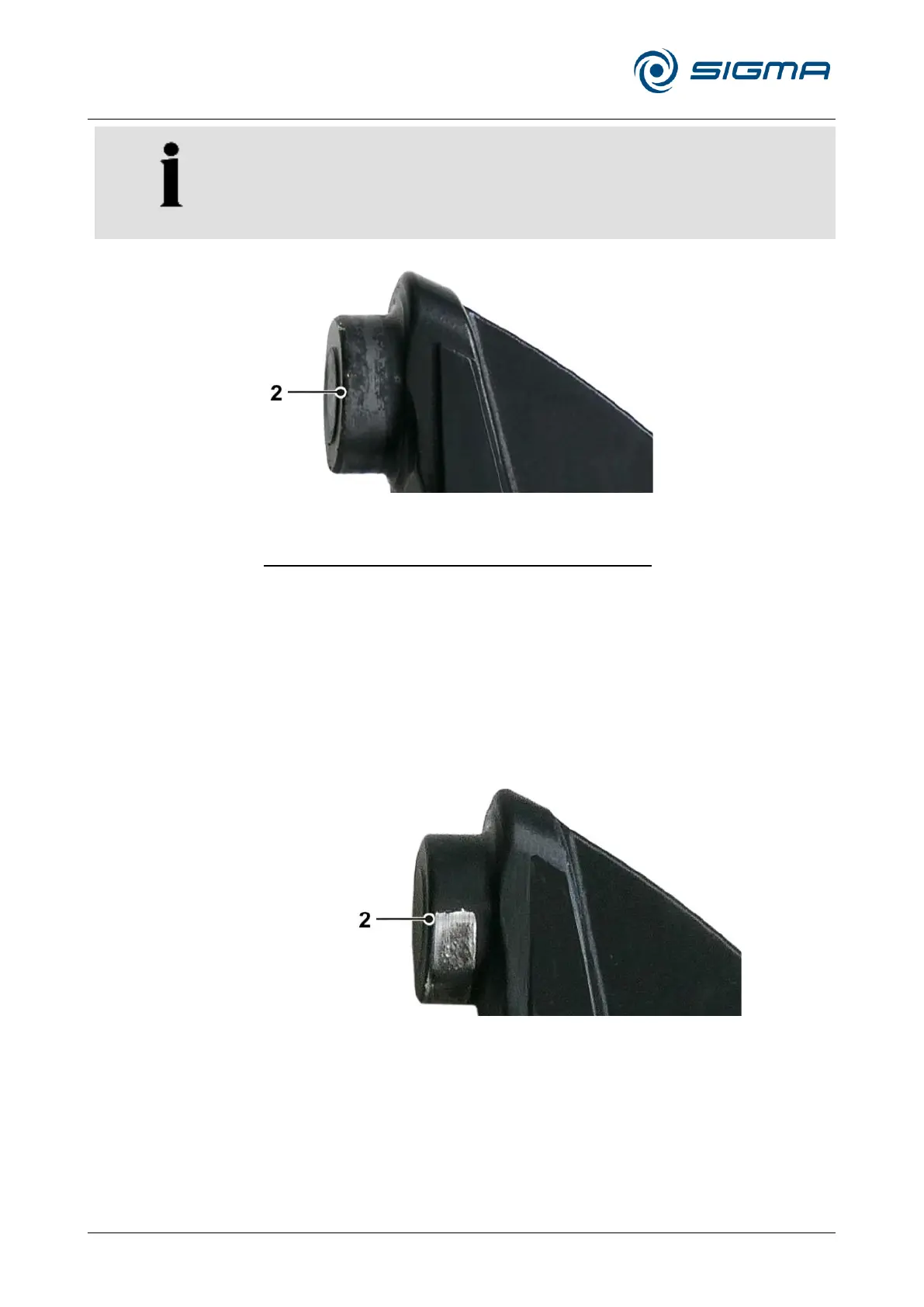

Traces of use on the black coating do not affect the anti-friction properties

(see the following illustration).

Fig. 7: Load-bearing bolt with traces of use – no greasing required

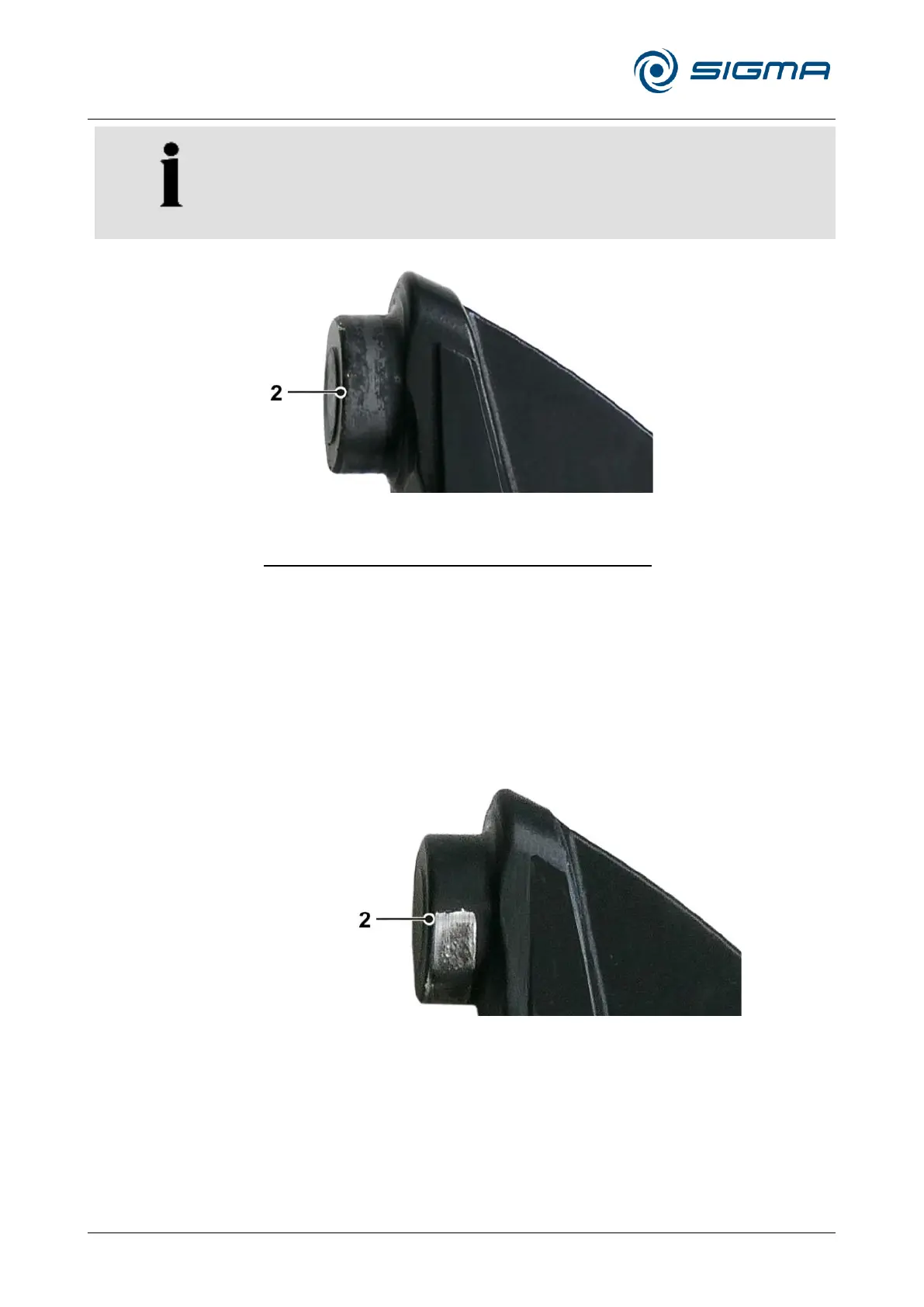

End of the service life of the "Comfort" rotor coating

When the coating has worn off nearly completely and the metallic surface

of the load-bearing bolt becomes visible (see the following illustration), the

anti-friction effect decreases. As a result, the buckets will swing out

irregularly, thereby potentially resulting in unwanted imbalance.

• From this moment on, the rotor must be used with greased load-bearing

bolts (heavy-duty grease for load-bearing bolts, ref. no. 71401) until it

reaches the end of its service life.

• Mark the rotor accordingly to prevent it from being used without grease

on the load-bearing bolts.

Fig. 8: Load-bearing bolt with completely worn-off coating – greasing required

Pos: 65 /010 Univers almodule/ Seitenw echsel @ 0\m od_1202116244 312_0.docx @ 105 @ @ 1

Loading...

Loading...