Pos: 64 /100 Sig ma/100 BA Zentrif ugen Sigma (S tandardmod ule)/030 Sicher heit/030-0060-0 070-0040 L ebensdauer Sigm a Comfort Rot orbeschichtung @ 105\mod_ 16953752519 61_68.docx @ 1222758 @ 4 @ 1

3.6.7.4 Service life of the Sigma "Comfort" rotor coating

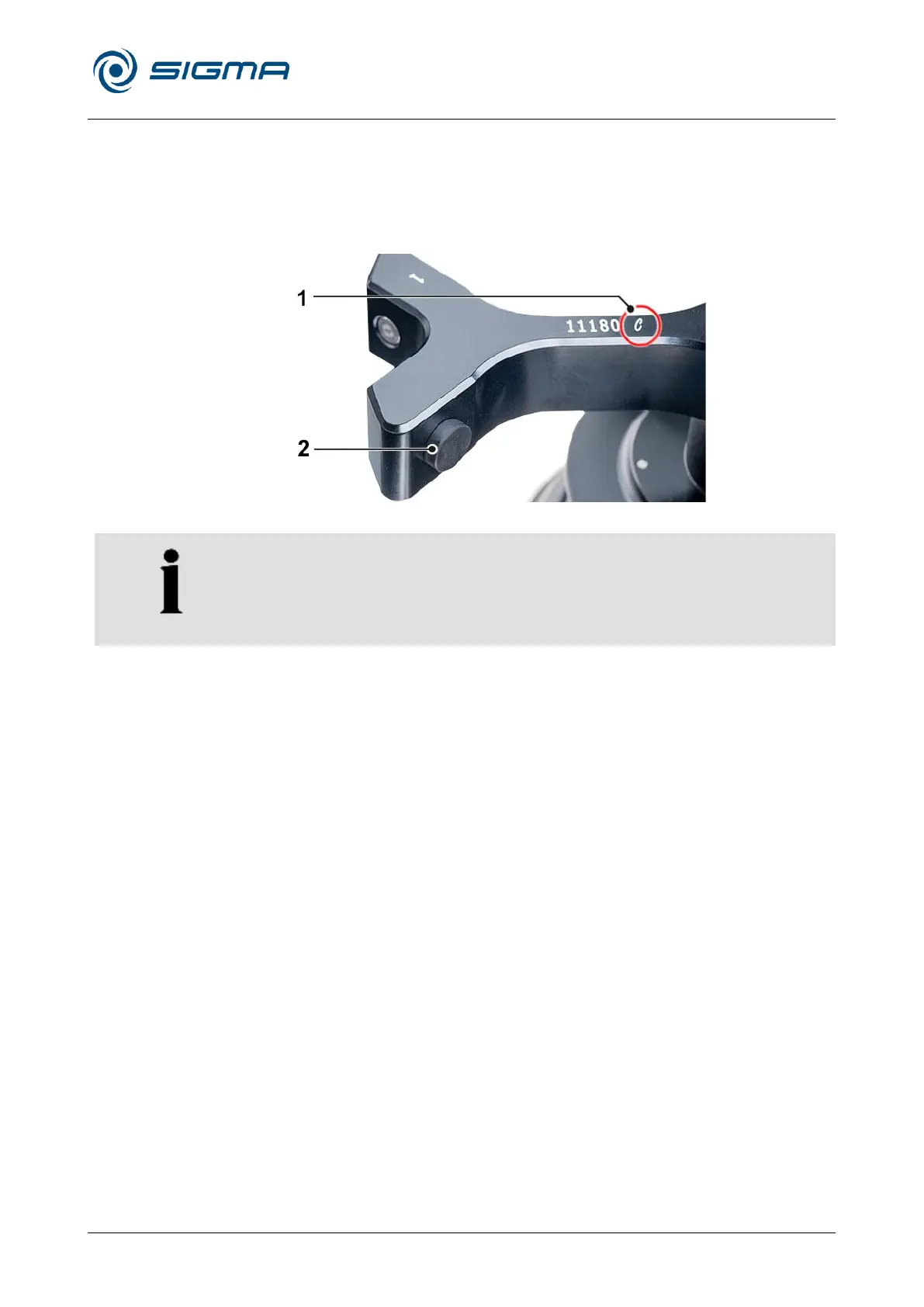

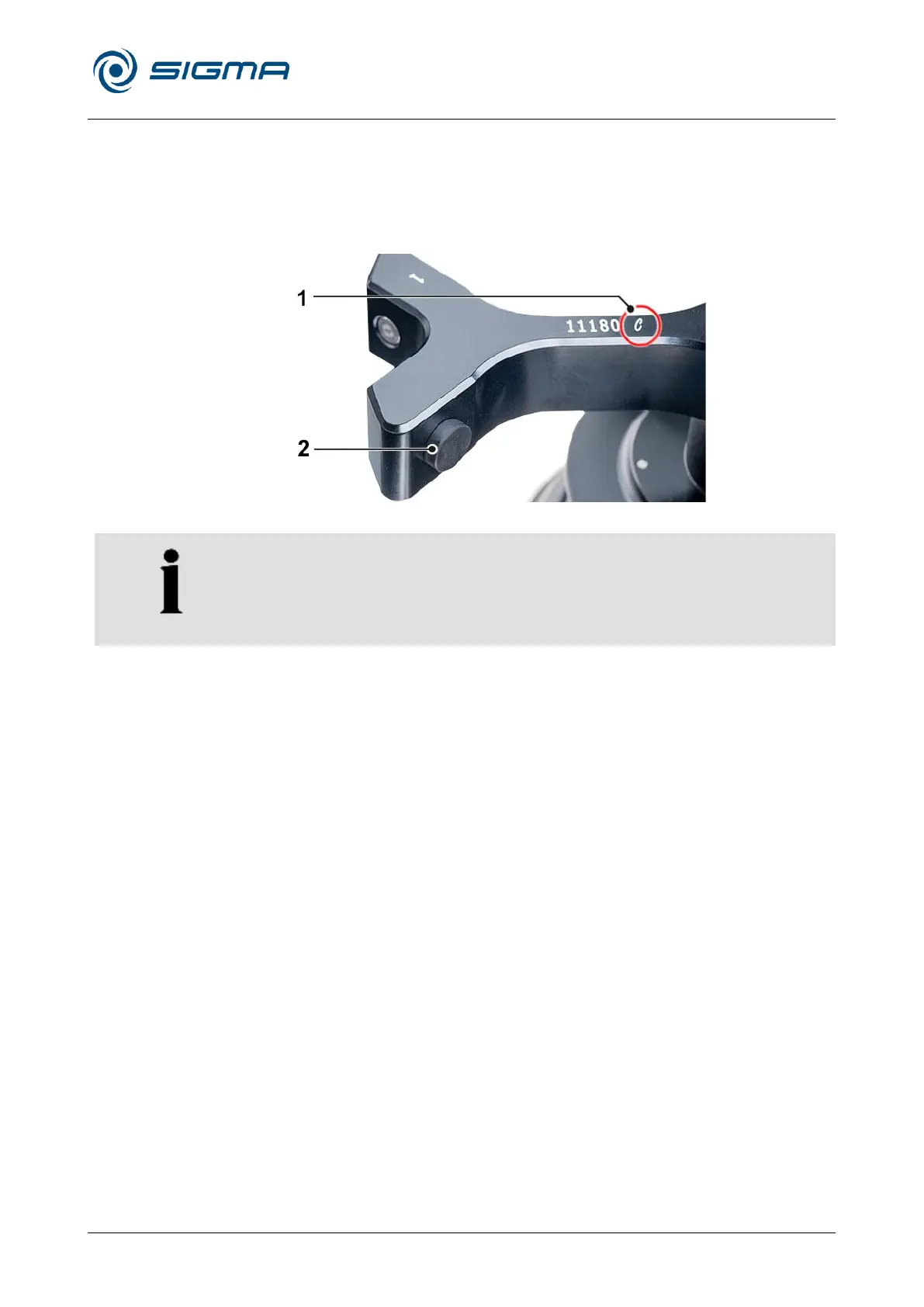

Marking

ll "Comfort" coated swing-out rotors have a "C" shown after their number.

The bolts of these rotors do not require any greasing during the service life

of the coating.

A portfolio of the available rotors with "Comfort" rotor coating and

information on the service life of the coating can be found in the document

"Sigma Comfort rotor coating", which is provided with every rotor with

"Comfort" rotor coating.

Service life

The service life of the coating varies and depends on the degree of

utilisation of the rotor. Tests have shown a service life of 7,000 to 40,000

cycles. The service life of the "Comfort" rotor coating can be increased by

way of specific measures:

The following factors have an influence on the service life:

• Speed/load:

The service life of the coating can be increased by a factor of 3.5 if the

speed or load is decreased by approximately 15%. In case of a load

decrease by 20%, the service life increases approximately by a factor of

5.5.

• Temperature:

The service life of the coating decreases by approximately 30% at lower

temperatures (approximately 4°C) compared to room temperature

(approximately 20°C).

• Use of buckets:

The buckets and the rotor form a joint unit. For the coating to reach the

maximum possible service life, ensure to always use the same set of

buckets and to install the individual buckets in their specific position

within the rotor.

• Cleaning frequency:

Regular cleaning of the accessories is indispensable. The more

frequently the rotor needs to be cleaned, the shorter the service life of

the coating will be.

Loading...

Loading...