Laboratory Centrifuge Sigma 3-16L

Laboratory Centrifuge Sigma 3-16L IVD

8 Maintenance and service

Version 03/2014, Rev. 2.22 of 24/10/2023 • sb

Original operating manual, part no. 0700902

Pos: 184 /100 Sigm a/100 BA Ze ntrifugen Sigma ( Standardmo dule)/080 Wartu ng und Instandh altung/080-0 010-0040-0 010 Tragbolze n mit Comfort Rot orbeschichtung (a ußer 2-7, 2- 16P, 2-16KL) @ 90\mod_1651 133147973_6 8.docx @ 9497 68 @ 4 @ 1

→

8.1.3.1 Load bearing bolts

Rotors with Sigma "Comfort" rotor coating

The load-bearing bolts of some of the swing-out rotors offered by Sigma

Laborzentrifugen GmbH have an anti-friction coating. This coating

prevents friction between the buckets and bolts.

The bolts do not require any greasing during the service life of the coating

(see chapter 3.6.7.4 - "Service life of the Sigma "Comfort" rotor coating")!

All "Comfort" coated swing-out rotors have a "C" shown after their number

(see chapter 3.6.7.1 - "Marking of rotors and accessories").

A portfolio of the available rotors with "Comfort" rotor coating and

information on the service life of the coating can be found in the document

"Sigma Comfort rotor coating", which is provided with every rotor with

"Comfort" rotor coating.

Rotors without Sigma "Comfort" rotor coating

For rotors that do not have or no longer have an anti-friction coating, the

load-bearing bolts must be greased. Only greased load-bearing bolts

ensure a uniform swing-out of the buckets and, therefore, the smooth

operation of the centrifuge. Load-bearing bolts that are insufficiently

greased may cause the centrifuge to stop due to an imbalance.

• Clean the load-bearing bolts and bucket groove in order to remove the

old grease.

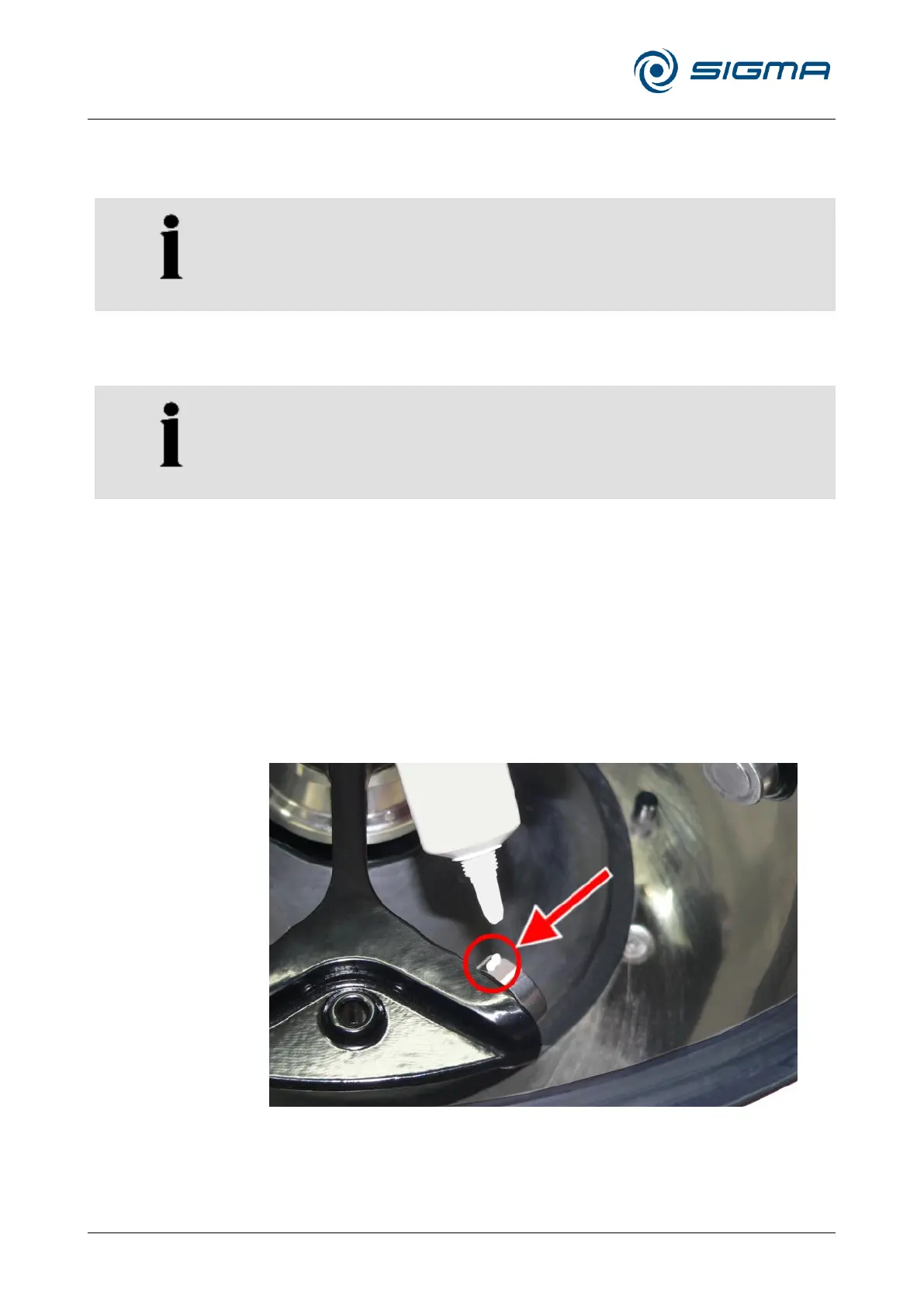

• Apply a small amount of heavy-duty grease for load-bearing bolts (ref.

no. 71401, see the following picture) to both load-bearing bolts of a

bucket.

Fig. 32: Sufficient quantity of grease for one bolt

• Install the bucket and swing it manually back and forth once in order to

distribute the grease.

• Repeat this process with all the other buckets.

Loading...

Loading...