65

EN

2

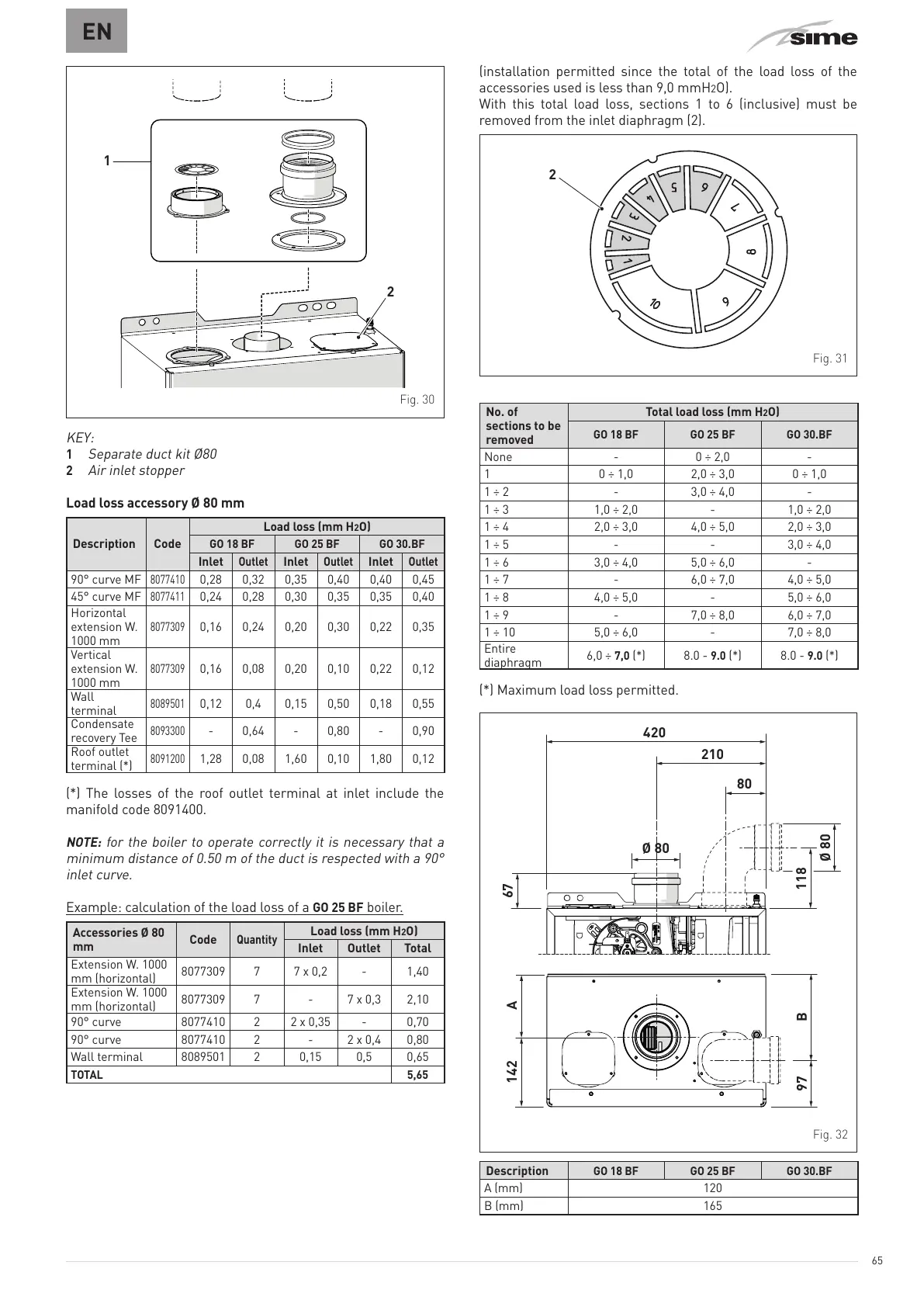

Fig. 30

KEY:

1

Separate duct kit Ø80

2

Air inlet stopper

Load loss accessory Ø 80 mm

Description Code

Load loss (mm H

2

O)

GO 18 BF GO 25 BF GO 30.BF

Inlet

Outlet

Inlet

Outlet

Inlet

Outlet

90° curve MF

8077410

0,28 0,32 0,35 0,40 0,40 0,45

45° curve MF

8077411

0,24 0,28 0,30 0,35 0,35 0,40

Horizontal

extension W.

1000 mm

8077309

0,16 0,24 0,20 0,30 0,22 0,35

Vertical

extension W.

1000 mm

8077309

0,16 0,08 0,20 0,10 0,22 0,12

Wall

terminal

8089501

0,12 0,4 0,15 0,50 0,18 0,55

Condensate

recovery Tee

8093300

- 0,64 - 0,80 - 0,90

Roof outlet

terminal (*)

8091200

1,28 0,08 1,60 0,10 1,80 0,12

(*) The losses of the roof outlet terminal at inlet include the

manifold code 8091400.

NOTE:

for the boiler to operate correctly it is necessary that a

minimum distance of 0.50 m of the duct is respected with a 90°

inlet curve.

Example: calculation of the load loss of a

GO 25 BF

boiler.

Accessories Ø 80

mm

Code

Quantity

Load loss (mm H

2

O)

Inlet Outlet Total

Extension W. 1000

mm (horizontal)

8077309 7 7 x 0,2 - 1,40

Extension W. 1000

mm (horizontal)

8077309 7 - 7 x 0,3 2,10

90° curve 8077410 2 2 x 0,35 - 0,70

90° curve 8077410 2 - 2 x 0,4 0,80

Wall terminal 8089501 2 0,15 0,5 0,65

TOTAL 5,65

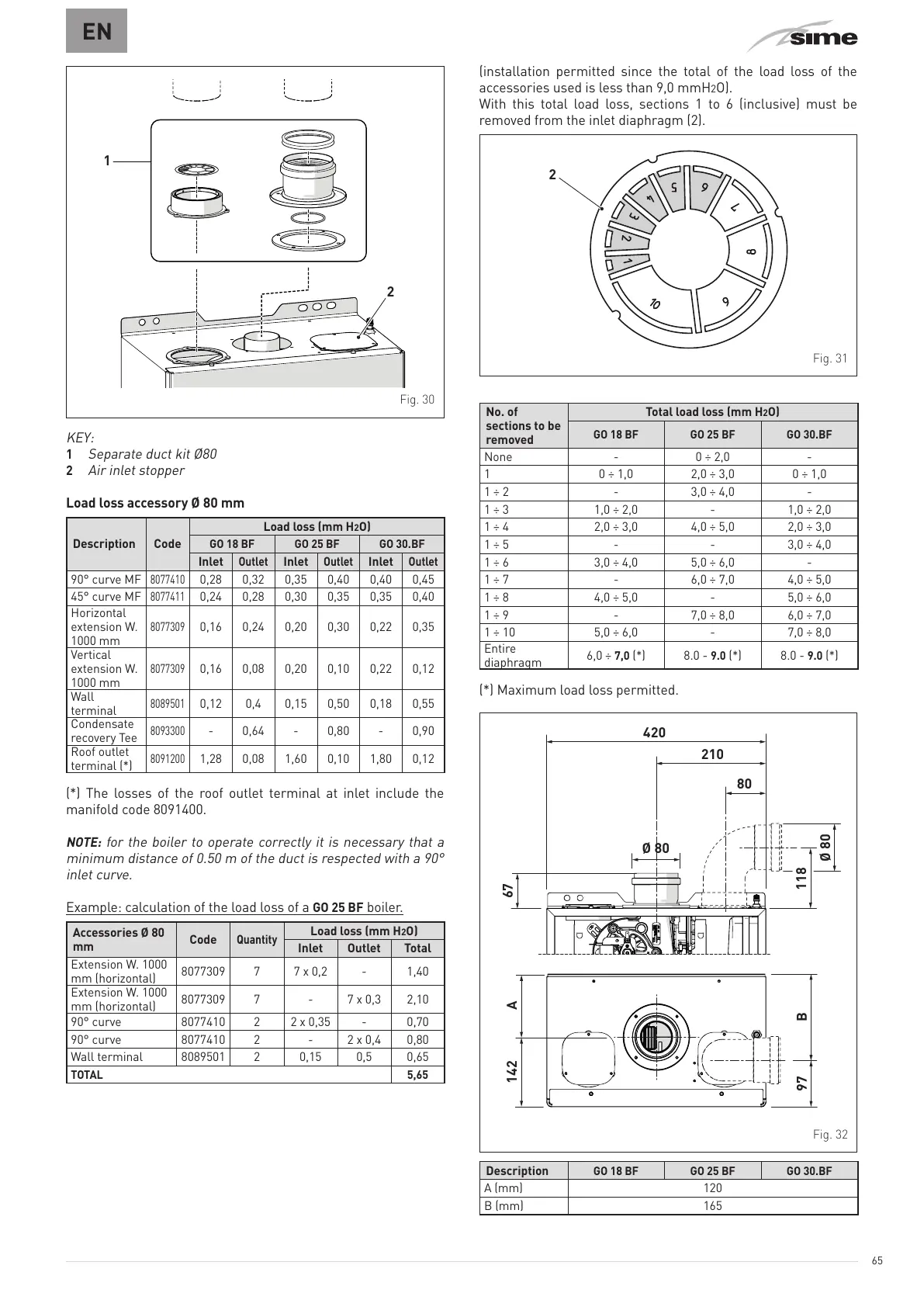

(installation permitted since the total of the load loss of the

accessories used is less than 9,0 mmH

2

O).

With this total load loss, sections 1 to 6 (inclusive) must be

removed from the inlet diaphragm (2).

Fig. 31

No. of

sections to be

removed

Total load loss (mm H

2

O)

GO 18 BF GO 25 BF GO 30.BF

None - 0 ÷ 2,0 -

1 0 ÷ 1,0 2,0 ÷ 3,0 0 ÷ 1,0

1 ÷ 2 - 3,0 ÷ 4,0 -

1 ÷ 3 1,0 ÷ 2,0 - 1,0 ÷ 2,0

1 ÷ 4 2,0 ÷ 3,0 4,0 ÷ 5,0 2,0 ÷ 3,0

1 ÷ 5 - - 3,0 ÷ 4,0

1 ÷ 6 3,0 ÷ 4,0 5,0 ÷ 6,0 -

1 ÷ 7 - 6,0 ÷ 7,0 4,0 ÷ 5,0

1 ÷ 8 4,0 ÷ 5,0 - 5,0 ÷ 6,0

1 ÷ 9 - 7,0 ÷ 8,0 6,0 ÷ 7,0

1 ÷ 10 5,0 ÷ 6,0 - 7,0 ÷ 8,0

Entire

diaphragm

6,0 ÷

7,0

(*) 8.0 -

9.0

(*) 8.0 -

9.0

(*)

(*) Maximum load loss permitted.

210

97 B

Ø 80

118

80

67

Ø 80

A142

Fig. 32

Description

GO 18 BF GO 25 BF GO 30.BF

A (mm) 120

B (mm) 165

Loading...

Loading...